Продукт, похожий на:

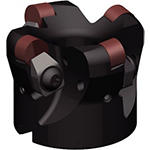

KSSR - RN • Shell Mills • Inch

Shell Mills

Номер материала1244356

Идентификатор каталога ISO4.00503R232Идентификатор каталога ANSI4.00503R232

- P Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Face Milling

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Обзор

- Режимы резания

- Загрузки

- Совместимые детали со стороны машины

- Совместимые детали со стороны заготовки

- Запчасти

- Обзор

- Вопросы и ответы

| Номер материала | 1244356 |

| Идентификатор каталога ISO | 4.00503R232 |

| Идентификатор каталога ANSI | 4.00503R232 |

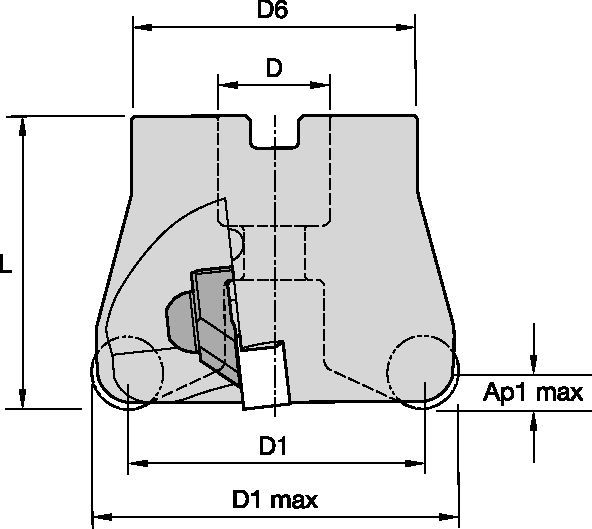

| [D1MAX] Maximum Cutting Diameter | 50 mm |

| [D1MAX] Maximum Cutting Diameter | 1.968 in |

| [D1] Effective Cutting Diameter | 37.3 mm |

| [D1] Effective Cutting Diameter | 1.468 in |

| [D] Adapter / Shank / Bore Diameter | 16 mm |

| [D] Adapter / Shank / Bore Diameter | .6299 in |

| [D6] Hub Diameter | 33 mm |

| [D6] Hub Diameter | 1.299 in |

| [L] Overall Length | 50 mm |

| [L] Overall Length | 1.968 in |

| [AP1MAX] 1st Maximum Cutting Depth | 3 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .1181 in |

| Number of Inserts | 3 |

| Gage Insert | RN__1207 |

| Weight Pounds | 1.1 |

Обрабатываемый материал

- Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Использование и область применения

Face Milling

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

Milling - Side and Face

Характеристики и преимущества

- First choice for face milling high-temp alloys and hard or hardened materials up to 60 HRC.

- Excellent productivity through massive reduction of machining time.

Создать решение для расчета подачи и скорости

После создания решения просто выберите значок Подача и Скорость, и наша система предоставит рекомендации. Вы можете настроить информацию, добавив свою машину и характеристики или внести изменения с помощью слайдеров.

Выбор пластины

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | – | (Sert geometri) | |||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | ..T.. | KY2100 / KYSM10 | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | ..T.. | KY2100 / KYSM10 | ..T.. | KY2100 / KYSM10 | ..T.. | KY2100 / KYSM10 |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | ..E | KY4300 / KYHS10 | ..T.. | KYS30 | ..T.. | KY2100 / KYSM10 |

| S3 | ..T.. | KYS30 | ..T.. | KYS30 | ..T.. | KY4300 / KYHS10 |

| S4 | – | – | – | – | – | – |

| H1 | ..E | KY4300 / KYHS10 | ..T.. | KY4300 / KYHS10 | – | – |

Подача

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .004 | .004 | .005 | .003 | .003 | .003 | .002 | .003 | .003 | .002 | .003 | .003 | .002 | .002 | .003 | ..E |

| ..T.. | .007 | .010 | .011 | .005 | .008 | .009 | .004 | .007 | .007 | .004 | .006 | .007 | .004 | .006 | .007 | ..T.. |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .004 | .005 | .005 | .003 | .004 | .004 | .003 | .003 | .003 | .003 | .003 | .003 | .003 | .003 | .003 | ..E |

| ..T.. | .008 | .012 | .013 | .006 | .009 | .010 | .005 | .008 | .009 | .005 | .007 | .008 | .005 | .007 | .008 | ..T.. |

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .008 | .009 | .009 | .006 | .006 | .007 | .005 | .006 | .006 | .005 | .005 | .006 | .005 | .005 | .006 | ..E |

| ..T.. | .014 | .022 | .024 | .010 | .016 | .018 | .009 | .014 | .015 | .008 | .013 | .014 | .008 | .013 | .014 | ..T.. |

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| ..E | .006 | .006 | .007 | .004 | .005 | .005 | .004 | .004 | .004 | .003 | .004 | .004 | .003 | .004 | .004 | ..E |

| ..T.. | .010 | .016 | .017 | .008 | .012 | .013 | .007 | .010 | .011 | .006 | .010 | .010 | .006 | .009 | .010 | ..T.. |

Скорость

Рекомендуемые начальные скорости резания [фут/мин]

| Malzeme grubu | KYS30 | KY2100 | KY4300 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | 3000 | 2400 | 1800 | 3960 | 3200 | 2380 | – | – | – | |

| 6 | 3000 | 2400 | 1800 | 3960 | 3200 | 2380 | – | – | – | |

| M | 1 | – | – | – | 3960 | 3200 | 2380 | – | – | – |

| 2 | – | – | – | 3740 | 3000 | – | – | – | – | |

| 3 | – | – | – | 2760 | 2400 | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 2640 | 2160 | 1680 | 3490 | 2860 | 2220 | 1680 | 1320 | 960 |

| 2 | 2640 | 2160 | 1680 | 3490 | 2860 | 2220 | 1680 | 1320 | 960 | |

| 3 | 3840 | 3120 | 2400 | 5080 | 4130 | 3180 | 2400 | 2040 | 1680 | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | 1200 | 1020 | 780 |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use