Q: How does Conforma Clad’s ability to extend wear life save end users time and money?

Jim Faust: We want to offer customers a clear value proposition. This means looking at the total value of the solution over the lifetime of the part, which includes the direct cost of the parts and elimination of downtime. There are two opportunities for us to make a large impact: reducing the number of replacements and reducing the number of unplanned outages.

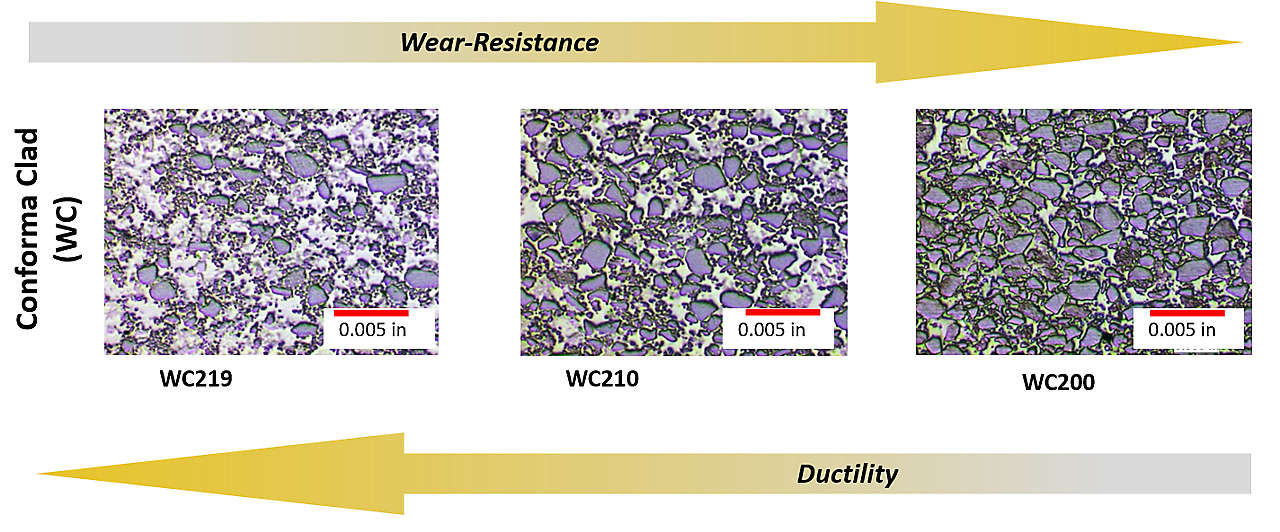

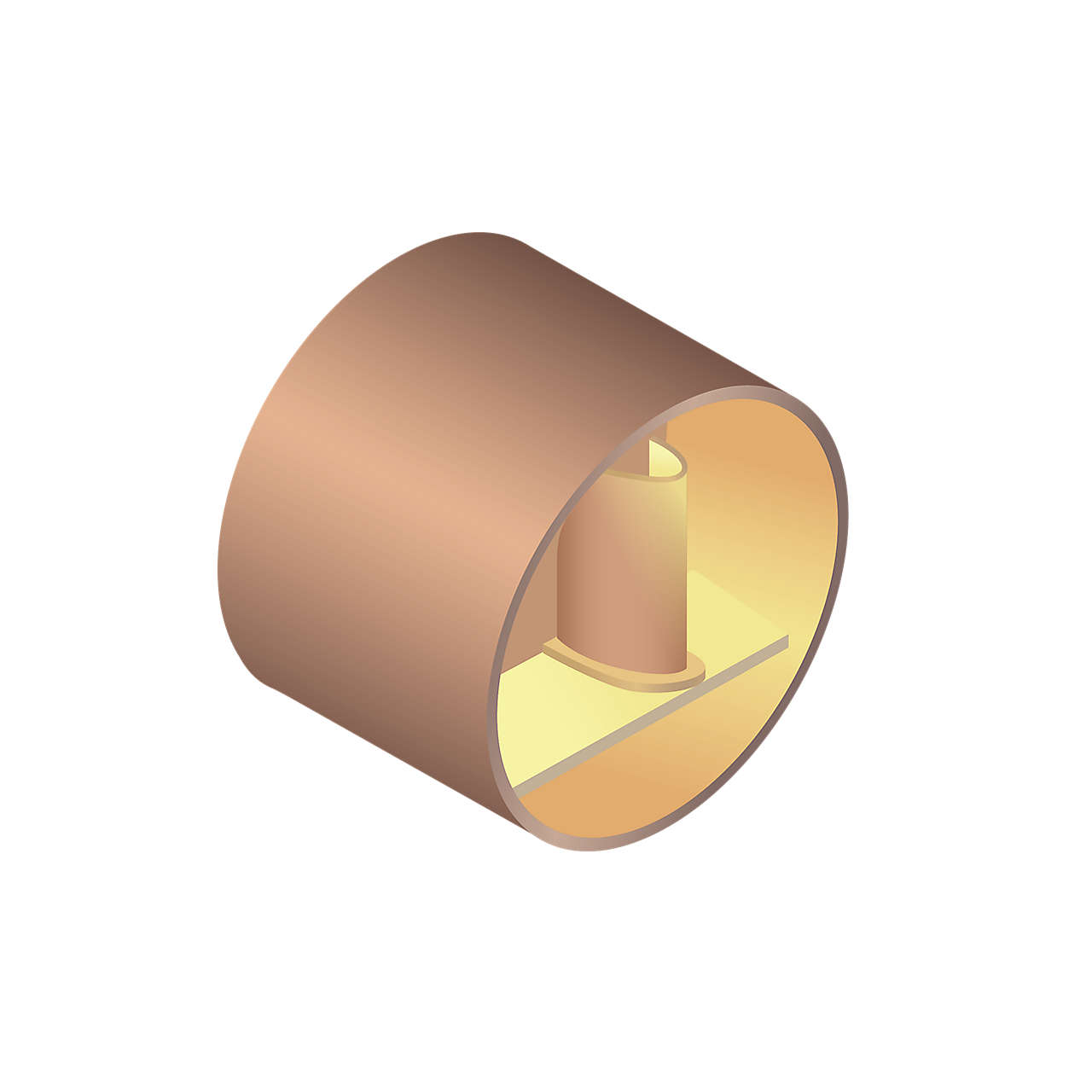

For example, in the petrochemical industry, rotating equipment teams are responsible for large and expensive pumps. When fully assembled, these pumps can cost upwards of $500,000 dollars each. They are used to pump heavy viscous fluids at various locations in a refinery. The wetted surfaces of these pumps experience heavy wear. Our technology can extend the wear resistance in these pumps 3-5X, and in some cases up to 20X over other solutions. This reduces the number of times those expensive components need to be replaced and saves our customers money.

In addition, we are also able to assist in wear monitoring so that informed decisions can be made about life expectancy and turnaround requirements. One service we offer is to measure cladding thickness during a shutdown. Because the cladding microstructure is uniform from top to bottom, this cladding thickness measurement allows us to extrapolate how much service life is left. This allows customers to plan outage cycles accordingly and eliminate costly unplanned downtime.