KenDrill™ SGL • 8 x D • Internal Coolant • Straight Shank • Inch

Solid Carbide Drill for Stainless Steel

物料号6351465

公制样本编号K212A06875SGL英制样本编号K212A06875SGL

- P 钢

- M 不锈钢

- S 高温合金

Drilling

Drilling: Stacked Plates

刀具尺寸: 2个排屑槽/2个刃带/冷却

DIN号码6535

DIN号码6537

钻孔 — 贯通式冷却

刀柄— 圆柱 平面度 ≤h6

螺旋角: 30°

钻孔深度 3x

钻孔深度 5x

钻孔深度 8x

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

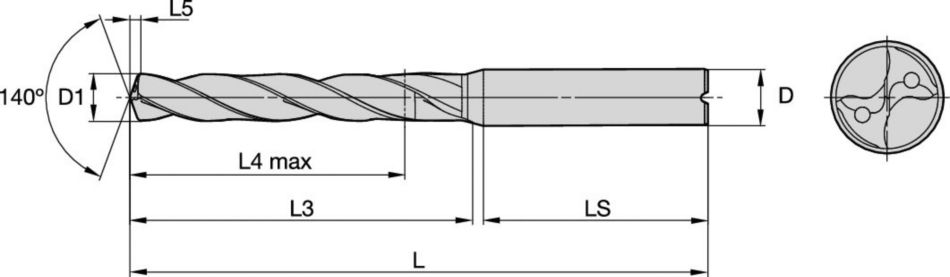

| 物料号 | 6351465 |

| 公制样本编号 | K212A06875SGL |

| 英制样本编号 | K212A06875SGL |

| 材质 | KCMS15 |

| [D1] 钻头直径 M | 17.4625 mm |

| [D1] 钻头直径 M | .6875 in |

| [L] 总长 | 210.566 mm |

| [L] 总长 | 8.29 in |

| [L3] 排屑槽长度 | 159.004 mm |

| [L3] 排屑槽长度 | 6.26 in |

| [L4] 最大钻孔深度 | 139.7 mm |

| [L4] 最大钻孔深度 | 5.5 in |

| [L5] 钻尖长度 | 2.58 mm |

| [L5] 钻尖长度 | .1016 in |

| [LS] 刀柄长度 | 48.514 mm |

| [LS] 刀柄长度 | 1.91 in |

| [D]适配接头/刀柄/镗孔直径 | 17.4625 mm |

| [D]适配接头/刀柄/镗孔直径 | .6875 in |

工件材料

- 钢

- 不锈钢

- 高温合金

Uses and application

Drilling

Drilling: Stacked Plates

刀具尺寸: 2个排屑槽/2个刃带/冷却

DIN号码6535

DIN号码6537

钻孔 — 贯通式冷却

刀柄— 圆柱 平面度 ≤h6

螺旋角: 30°

钻孔深度 3x

钻孔深度 5x

钻孔深度 8x

Grades

KCMS15

成分:PVD AlTiN 单层涂层,细晶粒硬质合金材质,卓越的表面精度。

应用:不锈钢及高温合金材料加工的首选。涂层具有极高的硬度和出色的耐磨性,同时还具有很好的耐高温性,并提高了在钢材料微量润滑加工中的性能。

Features and benefits

- SGL drills with through coolant for stainless steel and high-temperature alloys.

- By combining unique Kennametal features such as the all new SGL-Point-Geometry with a patented gashing, an unique Flute Design and a best in class coating into one tool, the B/K21*SGL drill is the ultimate high volume production tool.

- All new SGL point geometry with improved web thinning and patented gashing which migrate in a straight cutting edge enables high cutting parameters (feeds), improves hole quality and creates controlled chips which leads to a reliable performance.

- KCMS15 grade is a Monolayer PVD AlTiN coated fine grain carbide with superior surface finish. First choice for stainless steel, high-temperature resistant materials. The coating offers high hardness and excellent wear resistance as well as enhanced high-temperature properties increasing its applicability also to MQL machining of steel.

- The highly polished surface ensures superior chip evacuation even when low-pressure coolant is applied.

- Ideal point angle and tolerance make the B/K21_SGL series the preffered pilot drill for B27_SGL series Solid Carbide deep Hole Drills.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

公差

| 公差 • 公制 | ||

| 公称尺寸范围 | D1 公差 m7 | D 公差 h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

| 公差 • 英制 | ||

| 公称尺寸范围 | D1 公差 m7 | D 公差 h6 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

应用数据

| 材料 分组 |  |  | |||||||||||

| 切削速度 | 公制 | ||||||||||||

| 范围 | 推荐每转进给 | ||||||||||||

| 最小值 | 初始值 | 最大值 | |||||||||||

| 材料 分组 |  |  | |||||||||||

| 材料 分组 | 切削速度 | 英制 | |||||||||||

| 范围-SFM | 推荐每转进给 | ||||||||||||

| 最小值 | 初始值 | 最大值 | |||||||||||

|  | ||||||||||||

| 切削速度 | 公制 | ||||||||||||

| 范围 | 推荐每转进给 | ||||||||||||

| 材料 分组 | 最小值 | 初始值 | 最大值 | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| P | 1 | 110 | 160 | 210 | mm/r | 0,05–0,13 | 0,08–0,19 | 0,11–0,24 | 0,14–0,30 | 0,16–0,35 | 0,18–0,39 | 0,20–0,46 | 0,23–0,51 |

| 2 | 130 | 170 | 210 | mm/r | 0,05–0,13 | 0,08–0,17 | 0,11–0,20 | 0,14–0,24 | 0,16–0,28 | 0,18–0,32 | 0,20–0,37 | 0,23–0,41 | |

| 3 | 110 | 150 | 190 | mm/r | 0,08–0,13 | 0,12–0,19 | 0,14–0,24 | 0,17–0,30 | 0,20–0,35 | 0,22–0,39 | 0,26–0,46 | 0,29–0,51 | |

| 4 | 80 | 120 | 150 | mm/r | 0,08–0,12 | 0,11–0,18 | 0,12–0,23 | 0,15–0,28 | 0,17–0,33 | 0,19–0,37 | 0,22–0,43 | 0,25–0,48 | |

| 5 | 60 | 80 | 90 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,14–0,24 | 0,16–0,26 | |

| 6 | 60 | 70 | 80 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,14 | 0,08–0,18 | 0,11–0,21 | 0,14–0,24 | 0,16–0,26 | |

| M | 1 | 60 | 80 | 90 | mm/r | 0,04–0,08 | 0,06–0,14 | 0,08–0,19 | 0,11–0,21 | 0,13–0,23 | 0,14–0,24 | 0,16–0,26 | 0,19–0,29 |

| 2 | 50 | 80 | 80 | mm/r | 0,04–0,08 | 0,06–0,14 | 0,08–0,19 | 0,11–0,21 | 0,13–0,23 | 0,14–0,24 | 0,16–0,26 | 0,19–0,29 | |

| 3 | 40 | 50 | 70 | mm/r | 0,04–0,07 | 0,06–0,10 | 0,08–0,14 | 0,09–0,17 | 0,10–0,20 | 0,12–0,22 | 0,14–0,24 | 0,16–0,27 | |

| S | 1 | 20 | 20 | 20 | mm/r | 0,03–0,08 | 0,04–0,09 | 0,05–0,11 | 0,05–0,11 | 0,08–0,14 | 0,11–0,16 | 0,14–0,19 | 0,16–0,21 |

| 2 | 10 | 20 | 30 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,11 | 0,08–0,14 | 0,11–0,16 | 0,14–0,19 | 0,16–0,21 | |

| 3 | 10 | 20 | 50 | mm/r | 0,03–0,11 | 0,04–0,11 | 0,05–0,11 | 0,05–0,11 | 0,08–0,14 | 0,11–0,16 | 0,14–0,19 | 0,16–0,21 | |

| 4 | 30 | 50 | 60 | mm/r | 0,03–0,04 | 0,04–0,05 | 0,06–0,08 | 0,08–0,10 | 0,11–0,13 | 0,13–0,15 | 0,14–0,18 | 0,16–0,20 | |

I have read and accepted the Terms & Conditions of use