Product Similar To:

KTMD U Style Cutter 3/8" iC Weldon

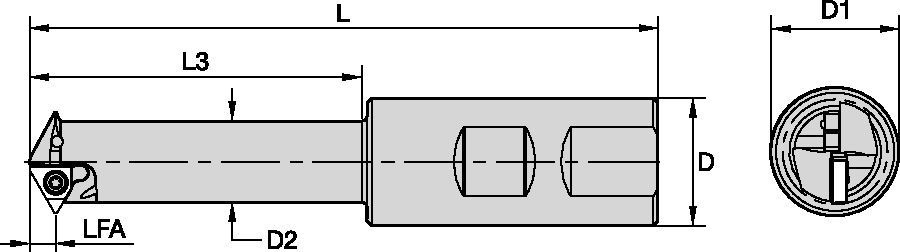

KTMD • U Style • 3/8" IC • Cutter Bodies

Material Number5593104

ISO Catalog IDKTMDUWD42L120Z4ANSI Catalog IDKTMDUWD42L120Z4

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Reviews

- Q&A

| Material Number | 5593104 |

| ISO Catalog ID | KTMDUWD42L120Z4 |

| ANSI Catalog ID | KTMDUWD42L120Z4 |

| [D1] Effective Cutting Diameter | 42 mm |

| [D1] Effective Cutting Diameter | 1.654 in |

| [D] Adapter / Shank / Bore Diameter | 40 mm |

| [D] Adapter / Shank / Bore Diameter | 1.575 in |

| [D2] Maximum Body Diameter | 34.2 mm |

| [D2] Maximum Body Diameter | 1.346 in |

| [L] Overall Length | 201 mm |

| [L] Overall Length | 7.913 in |

| [L3] Usable Length | 128 mm |

| [L3] Usable Length | 5.039 in |

| [LF] Functional Length | 193 mm |

| [LF] Functional Length | 7.598 in |

| [LFA] LF A Dimension | 8 mm |

| [LFA] LF A Dimension | 0.315 in |

| Number of Inserts | 4 |

| Max RPM | 3430 |

Workpiece Materials

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

| Thread Application per Toolholder | |||||||

| min thread Ø | |||||||

| toolholder | D1 mm | ISO (coarse) | ISO (fine) | UNC | UN/UNF/ | BSP(G) | partial 55° |

| KTMDUWD36L095Z3 | 36,50 | M42 x 4.5; M48 x 5.0; | M39 x 1.5; M39 x 2.0; | 1 3/4–5; | 1 9/16–16UN; 1 5/8–14UNS; | 1 1/4–11 | 1 5/8–16; 1 5/8–2 |

| KTMDUWD42L120Z4 | 42,00 | M48 x 5.0; M56 x 5.5; | M45 x 1.5; M45 x 2.0; | 2–4.5; | 1 3/4–16UN;1 3/4–14UNS; | 1 1/2–11 | 1 7/8–16; 1 7/8–12; |

Speeds & Feeds

KTMD • 3/8" IC

| Materials | Brinell | surface speeds | indexable inserts | |

| steel | HB | KC610M | KC635M | feed fz (mm/tooth) |

| P1 | 125 | 100–210 | 90–180 | 0,05–0,20 |

| P2 | 180 | 100–170 | 90–160 | 0,05–0,20 |

| P3 | 225 | 60–130 | 70–115 | 0,05–0,20 |

| P4 | 250 | 80–150 | 80–160 | 0,05–0,20 |

| P5 | 275 | 75–130 | 80–160 | 0,05–0,15 |

| P6 | 325 | 70–110 | 60–100 | 0,05–0,10 |

| stainless steel | ||||

| M1 | 180 | 100–170 | 120–180 | 0,05–0,10 |

| M2 | 250 | 70–140 | 100–140 | 0,05–0,10 |

| M3 | 330 | 70–120 | 100–120 | 0,05–0,10 |

| cast iron | ||||

| K1 | 180 | 60–130 | 100–120 | 0,02–0,08 |

| K2 | 220 | 60–125 | 80–100 | 0,05–0,15 |

| K3 | 260 | 50–90 | 60–90 | 0,05–0,10 |

| non-ferrous | ||||

| N1 | 60–100 | 100–250 | – | 0,05–0,25 |

| high-temp alloys | ||||

| S1 | 200 | 20–45 | 20–40 | 0,05–0,10 |

| S2 | 250 | 20–30 | 20–30 | 0,02–0,05 |

| S3 | 280 | 15–20 | 15–20 | 0,02–0,05 |

| S4 | 350 | 10–15 | 10–15 | 0,02–0,05 |

| hardened steel | ||||

| H1 | 55 HRC | 20–45 | 20–45 | 0,01–0,03 |

I have read and accepted the Terms & Conditions of use