Product Similar To :

Drill Fix™ DFT™ • ST Inserts

Drill Fix™ DFT™ • ST Inserts

Material Number4115434

ISO Catalog IDDFT06T308STANSI Catalog IDDFT06T308ST

- N Non-Ferrous

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 4115434 |

| ISO Catalog ID | DFT06T308ST |

| ANSI Catalog ID | DFT06T308ST |

| Grade | KD1425 |

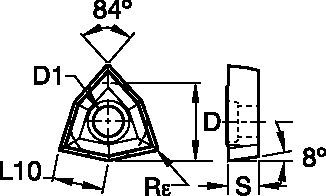

| [L10] Insert Cutting Edge Length | 6.52 mm |

| [L10] Insert Cutting Edge Length | 0.257 in |

| [D] Insert IC Size | 10 mm |

| [D] Insert IC Size | 0.394 in |

| [D1] Insert Hole Size | 4.4 mm |

| [D1] Insert Hole Size | 0.173 in |

| [S] Insert Thickness | 3.75 mm |

| [S] Insert Thickness | 0.148 in |

| [Rε] Corner Radius | 0.8 mm |

| [Rε] Corner Radius | 0.031 in |

Workpiece Materials

- Non-Ferrous

Grades

KD1425

Composition: A multimodal PCD grade with a range of grain sizes brazed onto a carbide substrate.

Application: Engineered for extreme abrasion resistance, combined with good edge strength for demanding applications. An ideal choice for high-silicon aluminium alloys, bi-metallic (AL/GCI) materials, MMC, carbon-fibre reinforced plastics, and other abrasive non-metallic materials.

Features and benefits

- PCD tipped inserts for machining non-ferrous materials.

- High wear resistance means long tool life.

- Increased productivity with high feed rates.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Application Data

DFT™ • PCD • Metric

| Metric | |||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Cutting Speed | Recommended Feed Rate (f) by Diameter | |||||||||

| Range | |||||||||||||||

| Min | Starting Value | Max | Ø | DFT03 16 | DFT05 25 | DFT06 33 | DFT07 41 | DFT09 49 | DFT11 69 | ||||||

| N | 1 | S | O | ST/C | KD1425 | 480 | 720 | 864 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 |

| I | ST/C | KD1425 | |||||||||||||

| 2 | S | O | ST/C | KD1425 | 447 | 670 | 804 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| I | ST/C | KD1425 | |||||||||||||

| 3 | S | O | ST/C | KD1425 | 413 | 619 | 743 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| I | ST/C | KD1425 | |||||||||||||

| 4 | S | O | ST/C | KD1425 | 447 | 670 | 804 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| I | ST/C | KD1425 | |||||||||||||

| 5 | S | O | ST/C | KD1425 | 480 | 720 | 864 | mm/r | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| I | ST/C | KD1425 | |||||||||||||

| Inch | |||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Cutting Speed | Recommended Feed Rate (f) by Diameter | |||||||||

| Range | |||||||||||||||

| Min | Starting Value | Max | Ø | DFT03 .625–.969" | DFT05 .984–1.250" | DFT06 1.313–1.563" | DFT07 1.625–1.875" | DFT09 1.938–2.125" | DFT11 2.750–3.250" | ||||||

| N | 1 | S | O | ST/C | KD1425 | 1575 | 2362 | 2834 | IPR | .002–.003 | .003–.004 | .004–.006 | .005–.006 | .006–.007 | .006–.007 |

| I | ST/C | KD1425 | |||||||||||||

| 2 | S | O | ST/C | KD1425 | 1465 | 2197 | 2636 | IPR | .002–.003 | .003–.004 | .004–.006 | .005–.006 | .006–.007 | .006–.007 | |

| I | ST/C | KD1425 | |||||||||||||

| 3 | S | O | ST/C | KD1425 | 1355 | 2032 | 2438 | IPR | .002–.003 | .003–.004 | .004–.006 | .005–.006 | .006–.007 | .006–.007 | |

| I | ST/C | KD1425 | |||||||||||||

| 4 | S | O | ST/C | KD1425 | 1465 | 2197 | 2636 | IPR | .002–.003 | .003–.004 | .004–.006 | .005–.006 | .006–.007 | .006–.007 | |

| I | ST/C | KD1425 | |||||||||||||

| 5 | S | O | ST/C | KD1425 | 1575 | 2362 | 2834 | IPR | .002–.003 | .003–.004 | .004–.006 | .005–.006 | .006–.007 | .006–.007 | |

| I | ST/C | KD1425 | |||||||||||||

| Metric | |||||||||||||||

| Cutting Speed | |||||||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||||

| Material | Condition | Pocket Seat | Geometry | Grade | Min | Starting Value | Max | Ø | DFT03 16 | DFT05 25 | DFT06 33 | DFT07 41 | DFT09 49 | DFT11 69 | |

| N | 1 | S | O | ST/C | KD1425 | 480 | 720 | 864 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 |

| 1 | S | I | ST/C | KD1425 | 480 | 720 | 864 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 2 | S | O | ST/C | KD1425 | 447 | 670 | 804 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 2 | S | I | ST/C | KD1425 | 447 | 670 | 804 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 3 | S | O | ST/C | KD1425 | 413 | 619 | 743 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 3 | S | I | ST/C | KD1425 | 413 | 619 | 743 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 4 | S | O | ST/C | KD1425 | 447 | 670 | 804 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 4 | S | I | ST/C | KD1425 | 447 | 670 | 804 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 5 | S | O | ST/C | KD1425 | 480 | 720 | 864 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

| 5 | S | I | ST/C | KD1425 | 480 | 720 | 864 | mm/omw | 0,05–0,07 | 0,07–0,09 | 0,10–0,14 | 0,12–0,16 | 0,14–0,18 | 0,14–0,18 | |

Warning

Warnings • Drill Fix DFR

| WARNING During through-hole operations, a slug or disc is produced as the tool breaks through the workpiece. When the drill is stationary and the workpiece is rotating, this slug may be hurled from the chuck by centrifugal force. Provide adequate shielding to protect bystanders. |

Dimension

| D | LS | CS |

| 32 | 58 | R 1/4 BSP |

| 40 | 68 | R 1/4 BSP |

| 50 | 68 | R 1/4 BSP |

I have read and accepted the Terms & Conditions of use