Product Similar To:

KenDrill™ HPS • 15 x D • Internal Coolant • Straight Shank • Metric

Solid Carbide Deep Hole Drill for Non-Ferrous Materials

Material Number3867722

ISO Catalog IDB271Z04763HPSANSI Catalog IDB271Z04763HPS

- N Non-Ferrous

Drilling: Stacked Plates

Drilling

Drilling: Inclined Exit

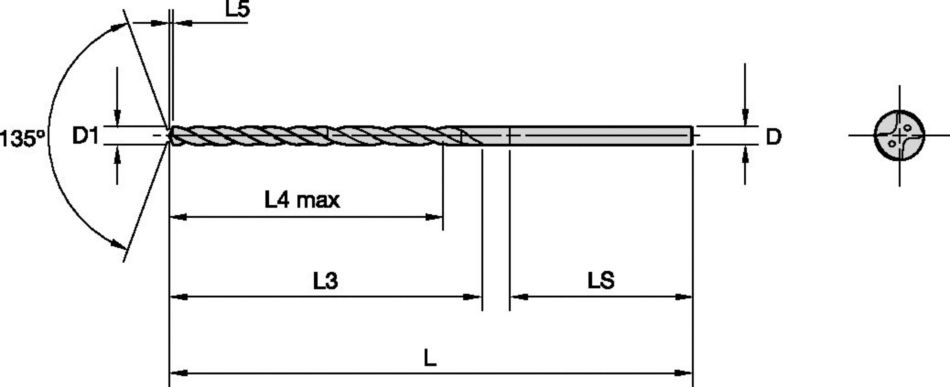

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 3867722 |

| ISO Catalog ID | B271Z04763HPS |

| ANSI Catalog ID | B271Z04763HPS |

| Grade | KN25 |

| [D1] Drill Diameter M | 4.763 mm |

| [D1] Drill Diameter M | 0.1875 in |

| [L] Overall Length | 124 mm |

| [L] Overall Length | 4.8819 in |

| [L3] Flute Length | 86 mm |

| [L3] Flute Length | 3.3858 in |

| [L4] Maximum Drilling Depth | 75 mm |

| [L4] Maximum Drilling Depth | 2.9528 in |

| [L5] Drill Point Length | 0.88 mm |

| [L5] Drill Point Length | 0.0346 in |

| [LS] Shank Length | 34 mm |

| [LS] Shank Length | 1.3386 in |

| [D] Adapter / Shank / Bore Diameter | 5 mm |

| [D] Adapter / Shank / Bore Diameter | 0.1969 in |

Workpiece Materials

- Non-Ferrous

Uses and application

Drilling: Stacked Plates

Drilling

Drilling: Inclined Exit

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

Grades

KN25

Composition: Uncoated, highly wear-resistant ultra-fine-grain carbide.

Application: Highly polished chip flute surfaces ensure superior chip evacuation and reduce tendency for built-up edges. First choice for deep-hole drilling of non-ferrous materials.

Features and benefits

- HP solid carbide deep-hole drills with through coolant for steel, cast iron, stainless steel, high-temperature alloys, and non-ferrous materials.

- Application-specific SC drill for drilling holes up to 15 x D up to 4x faster than conventional HSS and gun drills.

- Broadest diameter range on the market from .0938–.6299″ (2,383–16mm).

- KMH-point geometry is available as a semi-standard, especially for crankshaft applications.

- KN25™ Beyond uncoated grade (B27_HPS) with highly polished surface ensures superior chip evacuation and prevent built-up edge in aluminum and high-temp alloys, even when low-pressure coolant or MQL is applied.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| TOLERANCE • Inch | ||||

| Drills *HPG, *SGL, *HPR | Drills *HPS | |||

| nominal size range | D1 tolerance h7 | D tolerance h6 | D1 tolerance h8 | D tolerance h6 |

| .0394 to .1181 | .0000/-.0004 | .0000/-.0002 | .0000/-.0006 | .0000/-.0002 |

| .1181 to .2362 | .0000/-.0005 | .0000/-.0003 | .0000/-.0007 | .0000/-.0003 |

| .2362 to .3937 | .0000/-.0006 | .0000/-.0004 | .0000/-.0009 | .0000/-.0004 |

| .3937 to .7087 | .0000/-.0007 | .0000/-.0004 | .0000/-.0011 | .0000/-.0004 |

| TOLERANCE • Metric | ||||

| Drills *HPG, *SGL, *HPR | Drills *HPS | |||

| nominal size range | D1 tolerance h7 | D tolerance h6 | D1 tolerance h8 | D tolerance h6 |

| .0394 to .1181 | 0,000/-0,010 | 0,000/-0,006 | 0,000/-0,014 | 0,000/-0,006 |

| .1181 to .2362 | 0,000/-0,012 | 0,000/-0,008 | 0,000/-0,018 | 0,000/-0,008 |

| .2362 to .3937 | 0,000/-0,015 | 0,000/-0,009 | 0,000/-0,022 | 0,000/-0,009 |

| .3937 to .7087 | 0,000/-0,018 | 0,000/-0,011 | 0,000/-0,027 | 0,000/-0,011 |

Application Data

| Material |  |  | |||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | |||

| N | 1 | 120 | 200 | 300 | mm/r | 0,12–0,17 | 0,13–0,18 | 0,15–0,24 | 0,19–0,29 | 0,26–0,35 | 0,31–0,40 | 0,35–0,45 | 0,41–0,51 |

| 2 | 120 | 170 | 300 | mm/r | 0,13–0,18 | 0,14–0,19 | 0,16–0,25 | 0,20–0,30 | 0,28–0,37 | 0,33–0,42 | 0,38–0,48 | 0,44–0,54 | |

| 3 | 100 | 150 | 300 | mm/r | 0,13–0,18 | 0,14–0,19 | 0,16–0,25 | 0,20–0,30 | 0,28–0,37 | 0,33–0,42 | 0,38–0,48 | 0,44–0,54 | |

| 4 | 80 | 200 | 300 | mm/r | 0,03–0,05 | 0,03–0,06 | 0,03–0,06 | 0,04–0,06 | 0,05–0,07 | 0,05–0,08 | 0,05–0,08 | 0,06–0,09 | |

| Material |  |  | |||||||||||

| Material | Cutting Speed | Inch | |||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Min | Starting Value | Max | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | .551 | 5/8 .625 | |||

| N | 1 | 390 | 660 | 980 | IPR | .005–.007 | .005–.007 | .006–.009 | .008–.011 | .010–.014 | .012–.016 | .014–.018 | .016–.020 |

| 2 | 390 | 560 | 980 | IPR | .005–.007 | .006–.008 | .006–.010 | .008–.012 | .011–.015 | .013–.017 | .015–.019 | .017–.021 | |

| 3 | 330 | 490 | 980 | IPR | .005–.007 | .006–.008 | .006–.010 | .008–.012 | .011–.015 | .013–.017 | .015–.019 | .017–.021 | |

| 4 | 260 | 660 | 980 | IPR | .001–.002 | .001–.002 | .001–.002 | .002–.002 | .002–.003 | .002–.003 | .002–.003 | .002–.004 | |

|  | ||||||||||||

| Cutting Speed | Metric | ||||||||||||

| Range | Recommended Feed Rate (f) by Diameter | ||||||||||||

| Material | Min | Starting Value | Max | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | ||

| N | 1 | 120 | 200 | 300 | mm/r | 0,12–0,17 | 0,13–0,18 | 0,15–0,24 | 0,19–0,29 | 0,26–0,35 | 0,31–0,40 | 0,35–0,45 | 0,41–0,51 |

| 2 | 120 | 170 | 300 | mm/r | 0,13–0,18 | 0,14–0,19 | 0,16–0,25 | 0,20–0,30 | 0,28–0,37 | 0,33–0,42 | 0,38–0,48 | 0,44–0,54 | |

| 3 | 100 | 150 | 300 | mm/r | 0,13–0,18 | 0,14–0,19 | 0,16–0,25 | 0,20–0,30 | 0,28–0,37 | 0,33–0,42 | 0,38–0,48 | 0,44–0,54 | |

| 4 | 80 | 200 | 300 | mm/r | 0,03–0,05 | 0,03–0,06 | 0,03–0,06 | 0,04–0,06 | 0,05–0,07 | 0,05–0,08 | 0,05–0,08 | 0,06–0,09 | |

I have read and accepted the Terms & Conditions of use