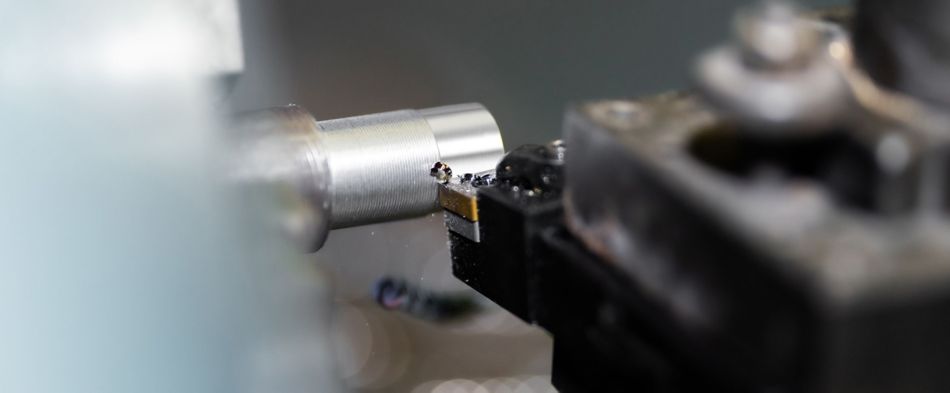

Her Kesimde Hassasiyet ve Güç

Kennametal’in mevcut KCU25’ine bir üst sürüm olarak geliştirilen KCU25B, yeni bir mühendislik tasarımına sahip KENGold™ PVD çok katmanlı kaplaması sayesinde arka arkaya farklı malzemelerin işlenmesini kolaylaştırırken aynı zamanda kesme işleminde tutarlılık sağlar. Bu nano-kompozit kaplama, daha iyi serbest yüzey ve ufalanma direnci sağlayan gelişmiş bir kaplama yapışmasına sahiptir. Birden fazla çeşitte malzeme içeren projelerinizde çelikler, paslanmaz çelikler, dökme demir, ısıl dirençli alaşımlar ve demir dışı malzemeler üzerinde çalışırken daha üstün bir iş çıkarabilir ve proje tamamlama tarihlerini erkene çekebilirsiniz.

KCU25B, çeşitli uç stilleri ve uygulamaları için mevcuttur.

- A2: Dilimleme

- A4: Kanal Açma, Tornalama ve Kesme

- K-Lock: R-stili

- Fix-Perfect: C-stili, D-stili, E-stili

- Beyond Evolution:Kanal Açma, Tornalama ve Kesme

- Kenloc: C-stili, D-stili, S-stili, T-stili, V-stili, W-stili

- Top Notch: D-stili, V-stili, K-stili

- Vida Bağlantılı: C-stili, D-stili, R-stili, S-stili, T-stili, V-stili, W-stili