Benzer Ürün:

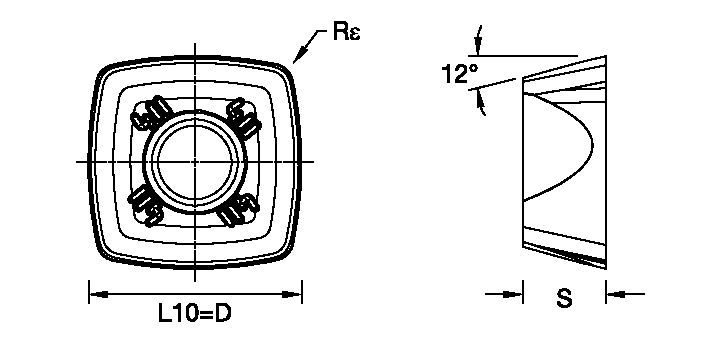

7792VXD12 Series • Carbide Insert • XDLT-D411 • Light Machining

High-feed copy milling insert with four cutting edges, precision ground.

Ürün Numarası5652248

ISO Katalog NoXDLT120512ERD411ANSI Catalog NoXDLT120512ERD411

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Ürün Numarası | 5652248 |

| ISO Katalog No | XDLT120512ERD411 |

| ANSI Catalog No | XDLT120512ERD411 |

| Grade | X500 |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | .5 in |

| [LI] Insert Length | 12.7 mm |

| [LI] Insert Length | .5 in |

| [S] Insert Thickness | 5.563 mm |

| [S] Insert Thickness | .219 in |

| [Rε] Corner Radius | 1.194 mm |

| [Rε] Corner Radius | .047 in |

| Average Chip Thickness [HM] | 0.05 mm |

| Average Chip Thickness [HM] | .002 in |

| [RT] Theoretical Corner Radius Programing | 2.73 mm |

| [RT] Theoretical Corner Radius Programing | .107 in |

İş Parçası Malzemeleri

- Steel

- Stainless Steel

- High-Temp Alloys

Kaliteler

X500

CVD TiN/TiCN/TiN coated carbide on tough substrate (X-Grade™ technology). For difficult applications with heavy impacts, vibrations, or unstable conditions. High stability against thermal cracks. Excellent grade for high-temperature alloys, stainless steels, and titanium.

Özellikler ve avantajlar

- Precision ground insert for best surface finish

- Single-sided copy milling insert for machining of steels, stainless steel and high-temperature alloys

İlerleme ve Devir hesaplamak için Çözüm Oluşturun

Bir çözüm oluşturduktan sonra, sadece İlerleme ve Devir simgesini seçin ve sistemimiz öneriler sunacaktır. Makinenizi ve teknik özelliklerinizi ekleyerek bilgileri özelleştirebilir veya kaydırıcıları kullanarak ayarlamalar yapabilirsiniz.

Uç Seçimi

Kesici uç seçme rehberi • IC (Kesici uç köşe radyüs ölçüsü) 12

| 7792 Series • IC12 • Insert Selection Guide | ||||||

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | – | (Sert geometri) | |||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1-P2 | ...M41 | KCPM40 | …M41 | KCPM40 | …GP | KCPM40 |

| P3-P4 | ...M41 | KCPM40 | …D411 | SP6519 | …D41 | KCPM40 |

| P5-P6 | ...M41 | KCPM40 | ...D41 | SP6519 | ...D41 | X500 |

| M1-M2 | ...M41 | KCSM40 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| M3 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| K1-K2 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| K3 | …M | KCK20B | …M | KCK20B | …D | KCPK30 |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S3 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| S4 | ...M41 | X500 | ...D411 | KCSM40 | ...D41 | KCSM40 |

| H1 | …M | KCKP10 | …M | KCKP10 | …D | KCPM40 |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use