Benzer Ürün:

KNS® • Arbor Mount • Inch

Slot milling cutter for multiple materials.

Ürün Numarası5614878

ISO Katalog NoKNSU100N17X34K200ANSI Catalog NoKNSU100N17X34K200

- P Steel

- M Stainless Steel

- K Cast Iron

- N Non-Ferrous

- S High-Temp Alloys

100055043

Slotting: Side

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Genel Bakış

- Uygulama bilgisi

- İndirilenler

- Uyumlu Parçalar Makine Tarafı

- Uyumlu Parçalar İş Parçası Tarafı

- Yedek Parçalar

- Yorum

- Soru&Cevap

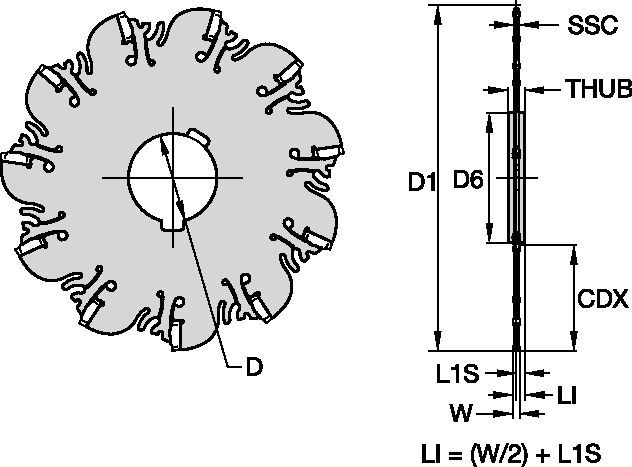

| Ürün Numarası | 5614878 |

| ISO Katalog No | KNSU100N17X34K200 |

| ANSI Catalog No | KNSU100N17X34K200 |

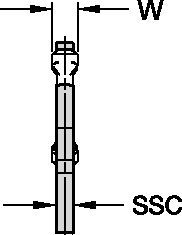

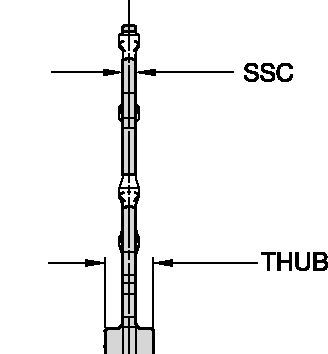

| Insert Size [SSC] | 34 |

| [BM] Cutting Width Minimum | 4 mm |

| [BM] Cutting Width Minimum | 0.158 in |

| [BMAX] Cutting Width Maximum | 4.9 mm |

| [BMAX] Cutting Width Maximum | 0.193 in |

| [D1] Effective Cutting Diameter | 254 mm |

| [D1] Effective Cutting Diameter | 10 in |

| [D] Adapter / Shank / Bore Diameter | 50.8 mm |

| [D] Adapter / Shank / Bore Diameter | 2 in |

| [D6] Hub Diameter | 69.85 mm |

| [D6] Hub Diameter | 2.75 in |

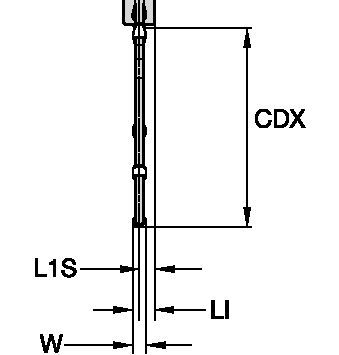

| [CDX] Radial Maximum Depth of Cut | 91.27 mm |

| [CDX] Radial Maximum Depth of Cut | 3.594 in |

| [L1S] Secondary Gage Length | 7.94 mm |

| [L1S] Secondary Gage Length | 0.312 in |

| [W1] Blade Width | 3.4 mm |

| [W1] Blade Width | 0.134 in |

| [THUB] Hub Thickness | 15.88 mm |

| [THUB] Hub Thickness | 0.625 in |

| Number of Inserts | 17 |

| Gage Insert | XCP34_____ |

| Weight Pounds | 2.96 |

| Max RPM | 320 |

İş Parçası Malzemeleri

- Steel

- Stainless Steel

- Cast Iron

- Non-Ferrous

- High-Temp Alloys

Kullanım ve uygulama alanları

100055043

Slotting: Side

Özellikler ve avantajlar

- The Double-V Design of the insert and the insert pocket securely holds the insert in place, minimises radial runout, providing high slot width accuracy and high repeatability.

- A unique self-clamping mechanism ensures easy insert exchange.

- Integral hub for high accuracy and repeatability.

- Two-keyway hub design for gang slotting applications.

İlerleme ve Devir hesaplamak için Çözüm Oluşturun

Bir çözüm oluşturduktan sonra, sadece İlerleme ve Devir simgesini seçin ve sistemimiz öneriler sunacaktır. Makinenizi ve teknik özelliklerinizi ekleyerek bilgileri özelleştirebilir veya kaydırıcıları kullanarak ayarlamalar yapabilirsiniz.

İlerlemeler

Önerilen başlangıç ilerlemeleri [mm]

| KNS® Slotting Cutter • Recommended Starting Feeds [mm/th] | ||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0,13 | 0,28 | 0,35 | 0,09 | 0,20 | 0,32 | 0,07 | 0,15 | 0,32 | 0,06 | 0,12 | 0,30 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

| KNS® Slotting Cutter • Recommended Starting Feeds [IPT] | ||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0.005 | 0.011 | 0.027 | 0.004 | 0.008 | 0.020 | 0.003 | 0.006 | 0.015 | 0.002 | 0.005 | 0.012 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

Hızlar

Önerilen başlangıç hızları [m/dk.]

| KNS® Slotting Cutter • Recommended Starting Speed [m/min] | ||||||||||

| Kalite | KCU25 | KCPK30 | KMF | |||||||

| Talaş kalınlığı hex mm | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | 260 | 230 | 215 | 455 | 395 | 370 | 295 | 260 | 245 |

| 2 | 220 | 190 | 160 | 280 | 255 | 230 | 250 | 215 | 180 | |

| 3 | 200 | 170 | 140 | 255 | 230 | 205 | 230 | 195 | 160 | |

| 4 | 180 | 150 | 120 | 225 | 185 | 160 | 205 | 170 | 135 | |

| 5 | 150 | 135 | 120 | 190 | 170 | 150 | 170 | 155 | 135 | |

| 6 | 130 | 100 | 80 | 160 | 135 | 110 | 150 | 115 | 90 | |

| M | 1 | 210 | 170 | 135 | 205 | 185 | 155 | 195 | 170 | 155 |

| 2 | 170 | 150 | 110 | 185 | 160 | 140 | 175 | 150 | 125 | |

| 3 | 130 | 120 | 85 | 145 | 130 | 115 | 130 | 115 | 90 | |

| K | 1 | 270 | 220 | 170 | 295 | 265 | 240 | – | – | – |

| 2 | 230 | 190 | 160 | 235 | 210 | 190 | – | – | – | |

| 3 | 210 | 160 | 140 | 195 | 175 | 160 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 |

| 2 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 | |

| 3 | 40 | 30 | 20 | – | – | – | 50 | 40 | 30 | |

| 4 | 55 | 40 | 25 | 50 | 45 | 35 | 55 | 50 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||

| KNS® Slotting Cutter • Recommended Starting Speed [SFM] | ||||||||||

| Kalite | KCPK30 | KCPK30 | KMF | |||||||

| Chip Thickness hex Inch | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | 855 | 755 | 705 | 1495 | 1295 | 1215 | 970 | 855 | 805 |

| 2 | 720 | 625 | 525 | 920 | 835 | 755 | 820 | 705 | 590 | |

| 3 | 655 | 560 | 460 | 835 | 755 | 675 | 755 | 640 | 525 | |

| 4 | 590 | 490 | 395 | 740 | 605 | 525 | 675 | 560 | 445 | |

| 5 | 490 | 445 | 395 | 625 | 560 | 490 | 560 | 510 | 445 | |

| 6 | 425 | 330 | 260 | 525 | 445 | 360 | 490 | 375 | 295 | |

| M | 1 | 690 | 560 | 445 | 675 | 605 | 510 | 640 | 560 | 510 |

| 2 | 560 | 490 | 360 | 605 | 525 | 460 | 575 | 490 | 410 | |

| 3 | 425 | 395 | 280 | 475 | 425 | 375 | 425 | 375 | 295 | |

| K | 1 | 885 | 720 | 560 | 970 | 870 | 785 | – | – | – |

| 2 | 755 | 625 | 525 | 770 | 690 | 625 | – | – | – | |

| 3 | 690 | 525 | 460 | 640 | 575 | 525 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 |

| 2 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 | |

| 3 | 130 | 100 | 65 | – | – | – | 165 | 130 | 100 | |

| 4 | 180 | 130 | 80 | 165 | 150 | 115 | 180 | 165 | 115 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||

Uç Seçimi

Kesici uç seçme rehberi

| KNS® Slotting Cutter • Insert Selection Guide | ||||||

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | (Sert geometri) | ||||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1-P2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P3-P4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P5-P6 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| M1-M2 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| M3 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| K1-K2 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| K3 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| N1-N2 | – | – | .S..GP | KCU25 | – | – |

| N3 | – | – | .S..GP | KCU25 | – | – |

| S1-S2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S3 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| H1 | – | – | – | – | – | – |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use