Benzer Ürün:

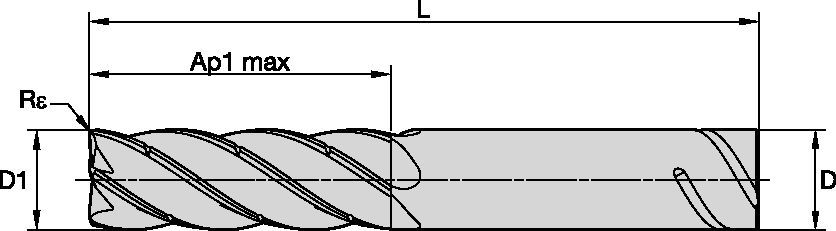

KOR5™ DA • Radiused • 5 Flutes • 3 x D • Internal Coolant • Safe-Lock™ Shank • Inch

KOR5™ DA Solid Carbide End Mill for Dynamic Milling of Aluminum

Ürün Numarası6754934

ISO Katalog NoKOR5RA0750R225SLR090IANSI Catalog NoKOR5RA0750R225SLR090I

- N Non-Ferrous

Trochoidal Milling

Through Coolant - Solid End Mill

Ramping: 4°

Tool Dimensions: Flute Configuration: 5

Helix Angle: 35°

Corner Style: Corner Radius

Corner Style: Square End

Side Milling/Shoulder Milling: Roughing

Side Milling/Shoulder Milling: Finishing

SAFE-LOCK Shank

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Ürün Numarası | 6754934 |

| ISO Katalog No | KOR5RA0750R225SLR090I |

| ANSI Catalog No | KOR5RA0750R225SLR090I |

| Grade | K600 |

| Adapter Style Machine Side | SAFE-LOCK |

| [D] Adapter / Shank / Bore Diameter | 19.05 mm |

| [D] Adapter / Shank / Bore Diameter | 0.75 in |

| [Re] Corner Radius | 2.275 mm |

| [Re] Corner Radius | 0.09 in |

| [Z] Number of Flutes | 5 |

| [D1] Effective Cutting Diameter | 19.05 mm |

| [D1] Effective Cutting Diameter | 0.75 in |

| [AP1MAX] 1st Maximum Cutting Depth | 57.15 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 2.25 in |

| [L] Overall Length | 127 mm |

| [L] Overall Length | 5 in |

İş Parçası Malzemeleri

- Non-Ferrous

Kullanım ve uygulama alanları

Trochoidal Milling

Through Coolant - Solid End Mill

Ramping: 4°

Tool Dimensions: Flute Configuration: 5

Helix Angle: 35°

Corner Style: Corner Radius

Corner Style: Square End

Side Milling/Shoulder Milling: Roughing

Side Milling/Shoulder Milling: Finishing

SAFE-LOCK Shank

Kaliteler

K600

Carbide grade made from high-quality, micrograin materials for cutting all types of workpiece materials. Very high toughness ensures a controlled wear rate. The micrograin structure enables extremely sharp cutting edges.

Özellikler ve avantajlar

- Designed for trochoidal milling with low radial engagement and full length of cut.

- With chip splitters for ideal chip evacuation.

- Proprietary flute form reduces vibrations and improves tool life.

- Helix angle tailored to minimize vibration and optimize tool life.

- Front end geometry designed for maximum tool life in helical and ramping operations.

- Safe-Lock for pull out protection.

İlerleme ve Devir hesaplamak için Çözüm Oluşturun

Bir çözüm oluşturduktan sonra, sadece İlerleme ve Devir simgesini seçin ve sistemimiz öneriler sunacaktır. Makinenizi ve teknik özelliklerinizi ekleyerek bilgileri özelleştirebilir veya kaydırıcıları kullanarak ayarlamalar yapabilirsiniz.

Uygulama bilgisi

|  |  | |||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | K600 | Recommended feed per tooth (IPT = inch/th) | |||||||||||

| D1 | |||||||||||||

| Malzeme grubu | A | B | Kesme hızı | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||

| ap | ae | ap | min | max | dec. | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| N | 1 | 0.5 x D1 | 0.5 x D1 | 0.25 x D1 | 640 | – | 6560 | IPT | 0.0030 | 0.0050 | 0.0060 | 0.0080 | 0.0090 |

| 2 | 0.5 x D1 | 0.5 x D1 | 0.25 x D1 | 640 | – | 4920 | IPT | 0.0025 | 0.0045 | 0.0055 | 0.0070 | 0.0085 | |

| Malzeme grubu |  |  | K600 | Diş başına önerilen ilerleme (fz = mm/Diş) | |||||||||

| A | B | Kesme hızı; | D1 | ||||||||||

| ap | ae | ap | Min. | Maks. | mm | 10,0 | 12,0 | 16,0 | 20,0 | 25,0 | |||

| N | 1 | 0,5 x D1 | 0,5 x D1 | 0,25 x D1 | 200 | – | 2000 | fz | 0,080 | 0,120 | 0,160 | 0,200 | 0,225 |

| 2 | 0,5 x D1 | 0,5 x D1 | 0,25 x D1 | 200 | – | 1500 | fz | 0,070 | 0,110 | 0,140 | 0,180 | 0,213 | |

TechnicalInfo

| Ae/D1 | 2% | 5% | 10% | 20% | 30% | 40% | 50% | 100% |

| Max Ap | Ap1 Max | Ap1 Max | Ap1 Max | Ap1 Max | 2 x D1 | 1 x D1 | .5 x D1 | .25 x D1 |

| Feed Multiplier | 3.60 | 2.30 | 1.70 | 1.25 | 1.09 | 1.02 | 1.00 | .90 |

| Ae/D1 | 2% | 5% | 10% | 20% | 30% | 40% | 50% | 100% |

| Max Ap | Ap1 Max | Ap1 Max | Ap1 Max | Ap1 Max | 2 x D1 | 1 x D1 | 0,5 x D1 | 0,25 x D1 |

| Feed Multiplier | 3,60 | 2,30 | 1,70 | 1,25 | 1,09 | 1,02 | 1,00 | 0,90 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data