Benzer Ürün:

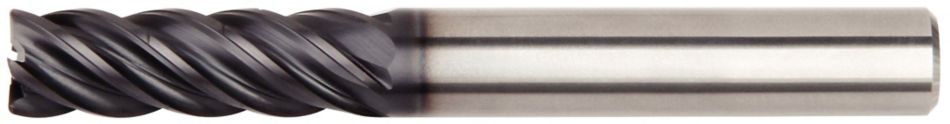

KOR5™ DS • Radiused • 5 Flutes • 3 x D • Weldon® Shank • Inch

KOR5™ DS Solid Carbide End Mill for Dynamic Milling of Steel and Stainless Steel

Ürün Numarası6769790

ISO Katalog NoKOR5RA0625R188HBR030ANSI Catalog NoKOR5RA0625R188HBR030

- P Steel

- M Stainless Steel

- K Cast Iron

- S High-Temp Alloys

- H Hardened Materials

Trochoidal Milling

Ramping: 5°

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 5

Shank - Cylindrical Weldon

Helix Angle: 40°

Corner Style: Corner Radius

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Ürün Numarası | 6769790 |

| ISO Katalog No | KOR5RA0625R188HBR030 |

| ANSI Catalog No | KOR5RA0625R188HBR030 |

| Grade | KC643M |

| Adapter Style Machine Side | Weldon |

| [Re] Corner Radius | 0.762 mm |

| [Re] Corner Radius | 0.03 in |

| [Z] Number of Flutes | 5 |

| [D1] Effective Cutting Diameter | 15.875 mm |

| [D1] Effective Cutting Diameter | 0.625 in |

| [D] Adapter / Shank / Bore Diameter | 15.875 mm |

| [D] Adapter / Shank / Bore Diameter | 0.625 in |

| [AP1MAX] 1st Maximum Cutting Depth | 47.625 mm |

| [AP1MAX] 1st Maximum Cutting Depth | 1.875 in |

| [L] Overall Length | 101.6 mm |

| [L] Overall Length | 4 in |

İş Parçası Malzemeleri

- Steel

- Stainless Steel

- Cast Iron

- High-Temp Alloys

- Hardened Materials

Kullanım ve uygulama alanları

Trochoidal Milling

Ramping: 5°

Side Milling/Shoulder Milling: Square End

Tool Dimensions: Flute Configuration: 5

Shank - Cylindrical Weldon

Helix Angle: 40°

Corner Style: Corner Radius

Kaliteler

KC643M

Coated fine-grain grade with PVD multilayer (AlTiN). KC643M™ is a very thin and hard PVD coating particularly suited for cutting steel, cast iron, stainless steel (wet), and titanium (wet). This grade can be used for materials with hardness up to 52 HRC.

Özellikler ve avantajlar

- Designed for trochoidal milling with low radial engagement and full length of cut.

- With chip deformers for ideal chip evacuation at high surface quality.

- Proprietary flute form reduces vibrations and improves tool life.

- Helix angle tailored to minimize vibration and optimize tool life.

- Front end geometry designed for maximum tool life in helical and ramping operations.

İlerleme ve Devir hesaplamak için Çözüm Oluşturun

Bir çözüm oluşturduktan sonra, sadece İlerleme ve Devir simgesini seçin ve sistemimiz öneriler sunacaktır. Makinenizi ve teknik özelliklerinizi ekleyerek bilgileri özelleştirebilir veya kaydırıcıları kullanarak ayarlamalar yapabilirsiniz.

TechnicalInfo

KOR5™ DS • 5 Flutes • 3 x D • Adjustment factor table for feed calculation • Inch

| Ae/D1 | 0.50% | 1.00% | 1.50% | 2.00% | 4.00% | 5.00% | 8.00% | 10.00% | |

| Speed factor | Kv | 2.15 | 2.11 | 2.07 | 1.48 | 1.11 | 1.07 | 1.04 | 1.00 |

| Feed factor | KFz | 1.65 | 1.53 | 1.47 | 1.41 | 1.35 | 1.29 | 1.18 | 1.00 |

Uygulama bilgisi

KOR5™ DS • 5 Flutes • 3 x D • Application Data • Inch

| Malzeme grubu |  |  | |||||||||||

| Dik kenar frezeleme (A) | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||

| A | KC643M | D1 | |||||||||||

| Kesme hızı | frac. | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||

| ap | ae | Min. | Maks. | dec. | .2500 | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 0 | 3 x D | 0.1 x D | 500 | – | 1440 | IPT | .0022 | .0033 | .0041 | .0047 | .0053 | .0059 |

| 1 | 3 x D | 0.1 x D | 500 | – | 1440 | IPT | .0022 | .0033 | .0041 | .0047 | .0053 | .0059 | |

| 2 | 3 x D | 0.1 x D | 460 | – | 1370 | IPT | .0022 | .0033 | .0041 | .0047 | .0053 | .0059 | |

| 3 | 3 x D | 0.1 x D | 400 | – | 1150 | IPT | .0018 | .0027 | .0035 | .0041 | .0046 | .0054 | |

| 4 | 3 x D | 0.1 x D | 300 | – | 1080 | IPT | .0017 | .0025 | .0031 | .0036 | .0040 | .0046 | |

| 5 | 3 x D | 0.1 x D | 200 | – | 720 | IPT | .0015 | .0022 | .0028 | .0033 | .0037 | .0043 | |

| 6 | 3 x D | 0.1 x D | 170 | – | 540 | IPT | .0012 | .0018 | .0023 | .0027 | .0030 | .0034 | |

| M | 1 | 3 x D | 0.1 x D | 300 | – | 830 | IPT | .0018 | .0027 | .0035 | .0041 | .0046 | .0054 |

| 2 | 3 x D | 0.1 x D | 200 | – | 580 | IPT | .0015 | .0022 | .0028 | .0033 | .0037 | .0043 | |

| 3 | 3 x D | 0.1 x D | 200 | – | 510 | IPT | .0012 | .0018 | .0023 | .0027 | .0030 | .0034 | |

| K | 1 | 3 x D | 0.1 x D | 400 | – | 1080 | IPT | .0022 | .0033 | .0041 | .0047 | .0053 | .0059 |

| 2 | 3 x D | 0.1 x D | 370 | – | 1010 | IPT | .0018 | .0027 | .0035 | .0041 | .0046 | .0054 | |

| 3 | 3 x D | 0.1 x D | 370 | – | 940 | IPT | .0015 | .0022 | .0028 | .0033 | .0037 | .0043 | |

| S | 1 | 3 x D | 0.1 x D | 170 | – | 650 | IPT | .0018 | .0027 | .0035 | .0041 | .0046 | .0054 |

| 2 | 3 x D | 0.1 x D | 80 | – | 580 | IPT | .0015 | .0022 | .0028 | .0033 | .0037 | .0043 | |

| 3 | 3 x D | 0.1 x D | 80 | – | 290 | IPT | .0010 | .0015 | .0018 | .0022 | .0025 | .0029 | |

| 4 | 3 x D | 0.1 x D | 170 | – | 430 | IPT | .0013 | .0020 | .0026 | .0030 | .0034 | .0040 | |

| H | 1 | 3 x D | 0.1 x D | 270 | – | 1010 | IPT | .0017 | .0025 | .0031 | .0036 | .0040 | .0046 |

| 2 | 3 x D | 0.1 x D | 230 | – | 870 | IPT | .0012 | .0018 | .0023 | .0027 | .0030 | .0034 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use