Benzer Ürün:

T651 • Metrik DIN 376 • Form C Yarı düşürülmüş ağızlama pahı • Rüzgar enerjisi

Beyond™ Helisel kanallı HSS-E-PM Kılavuzlar • Kör delikler

Ürün Numarası4153887

ISO Katalog NoT651M360X400R6HX-D6ANSI Catalog NoT651M360X400R6HX-D6

- P Steel

Threading: Blind Hole

Class of Fit: 6HX

DIN number 376

Chamfer Form C (2–3)

HSS-E-PM

Through Coolant: Axial: Tapping

Manufacturer’s Specs: M

Tapping Helix Angle: 15°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

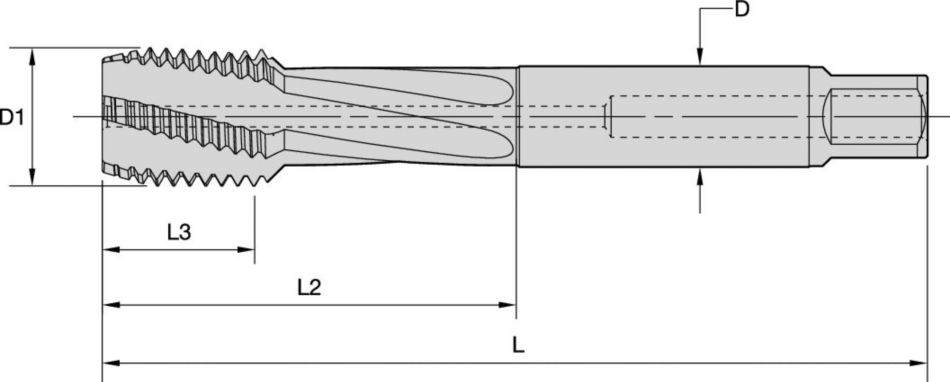

| Ürün Numarası | 4153887 |

| ISO Katalog No | T651M360X400R6HX-D6 |

| ANSI Catalog No | T651M360X400R6HX-D6 |

| Grade | KP6525 |

| [D1-TDZ] Thread Diameter Size | M36 X 4 |

| [L] Overall Length | 200 mm |

| [L] Overall Length | 7.87 in |

| [L3] Thread Length | 40 mm |

| [L3] Thread Length | 1.57 in |

| [L2] Useable Length | 110 mm |

| [L2] Useable Length | 4.33 in |

| [D] Adapter / Shank / Bore Diameter | 28 mm |

| [D] Adapter / Shank / Bore Diameter | 1.1024 in |

| [Z] Number of Flutes | 5 |

| Dimension Standard | DIN 376 |

| Thread Tolerance Class ISO | 6HX-I |

İş Parçası Malzemeleri

- Steel

Kullanım ve uygulama alanları

Threading: Blind Hole

Class of Fit: 6HX

DIN number 376

Chamfer Form C (2–3)

HSS-E-PM

Through Coolant: Axial: Tapping

Manufacturer’s Specs: M

Tapping Helix Angle: 15°

Kaliteler

KP6525

Coated HSS-E-PM. PVD — heat- and wear-resistant high vanadium — cobalt powder metal HSS substrate coated with wear-resistant TiCN base layer and low-friction TiN top layer. Use in steel, cast iron, and cast aluminum with silicon.

Özellikler ve avantajlar

- KP6525 TiCN + TiN, çelik ve dökme demirde vida dişi açma için uygun.

İlerleme ve Devir hesaplamak için Çözüm Oluşturun

Bir çözüm oluşturduktan sonra, sadece İlerleme ve Devir simgesini seçin ve sistemimiz öneriler sunacaktır. Makinenizi ve teknik özelliklerinizi ekleyerek bilgileri özelleştirebilir veya kaydırıcıları kullanarak ayarlamalar yapabilirsiniz.

Uygulama bilgisi

| HSS-E-PM Taps • Grades KP6505 KP6525 KM6515 | ||||||||||||||||

| Tapping Operation | Kılavuz tipi | Grade1 | Kesme hızı | |||||||||||||

| Başlangıç değeri | ||||||||||||||||

| m/min | 3 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | |||

| SFM | 10 | 16 | 33 | 49 | 66 | 82 | 98 | 115 | 131 | 148 | 164 | 180 | 197 | |||

| P1 • Low-Carbon Steels, Long Chipping • Content: C 0.25% • Tensile Strength RM (MPa*): 530 • Hardness (HB) or HRC: 125 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 38 | 30 | 45 | |||||||||||

| 125 | 98 | 148 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 23 | 18 | 27 | |||||||||||

| 75 | 59 | 89 | ||||||||||||||

| P2 • Low-Carbon Steels, Free Machining, and Short Chipping • Content C 0.25% • Tensile Strength RM (MPa*): 650 • Hardness (HB) or HRC: 220 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 33 | 25 | 40 | |||||||||||

| 108 | 82 | 131 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 20 | 15 | 25 | |||||||||||

| 65 | 49 | 82 | ||||||||||||||

| P3 • Medium- and High-Plain Carbon Steels, Low-Alloyed • Content C | ||||||||||||||||

| Through Holes | T620 | KP6525 | 28 | 20 | 35 | |||||||||||

| 92 | 66 | 115 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 17 | 12 | 21 | |||||||||||

| 55 | 59 | 69 | ||||||||||||||

| P5 • Ferritic, Martensitic, and PH Stainless Steels • Content C= 0-0.4% • Tensile Strength RM (MPa*): 600–850 • Hardness (HB) HRC: 330 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 18 | 10 | 25 | |||||||||||

| 59 | 33 | 82 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 11 | 6 | 15 | |||||||||||

| 35 | 20 | 49 | ||||||||||||||

| P6 • High-Strength Ferritic, Martensitic, and PH Stainless Steels • Content C=0.1-0.6% • Tensile Strength RM (MPa*): 900-1350 • Hardness (HB) HRC: 350–450 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 10 | 5 | 15 | |||||||||||

| 33 | 16 | 49 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 6 | 3 | 9 | |||||||||||

| 20 | 10 | 30 | ||||||||||||||

| M1 • Austenitic Stainless Steel • Content C=0.05-0.15% • Tensile Strength RM (MPa*): 650 • Hardness (HB) or HRC: 130-200 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| M2 • High-Strength Austenitic Stainless and Cast Stainless Steels • Content C=0.05-0.15% • Tensile Strength RM (MPa*): 500 - 700 • Hardness (HB) or HRC: 150-230 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| M3 • Duplex Steel • Content C=0.05-0.2 % • Tensile Strength RM (MPa*): 900 • Hardness (HB) HRC: 135-275 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| K1 • Cast and Low-Strength Ductile Irons • Tensile Strength RM (MPa*): 150-400 • Hardness (HB) or HRC: 120-290 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 45 | 30 | 60 | |||||||||||

| 148 | 98 | 197 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 27 | 18 | 36 | |||||||||||

| 90 | 59 | 118 | ||||||||||||||

| K2 • Low- and Medium-Strength CGI and Ductile Irons • Tensile Strength RM (MPa*): 400-600 • Hardness (HB) or HRC: 130-260 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 38 | 25 | 50 | |||||||||||

| 125 | 82 | 164 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 23 | 15 | 30 | |||||||||||

| 75 | 49 | 98 | ||||||||||||||

| K3 • High-Strength Ductile and Austempered Ductile Iron • Tensile Strength RM (MPa*): 600-900 • Hardness (HB) or HRC: 180-350 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 30 | 20 | 40 | |||||||||||

| 98 | 66 | 131 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 18 | 12 | 25 | |||||||||||

| 59 | 39 | 82 | ||||||||||||||

| HSS-E-PM Taps • Grades KP6505 KP6525 KM6515 | ||||||||||||||||

| Tapping Operation | Kılavuz tipi | Kalite | Kesme hızı | |||||||||||||

| Başlangıç değeri | ||||||||||||||||

| m/min | 3 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | |||

| SFM | 10 | 16 | 33 | 49 | 66 | 82 | 98 | 115 | 131 | 148 | 164 | 180 | 197 | |||

| P1 • Low-Carbon Steels, Long Chipping • Content: C 0.25% • Tensile Strength RM (MPa*): 530 • Hardness (HB) or HRC: 125 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 38 | 30 | 45 | |||||||||||

| 125 | 98 | 148 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 23 | 18 | 27 | |||||||||||

| 75 | 59 | 89 | ||||||||||||||

| P2 • Low-Carbon Steels, Free Machining, and Short Chipping • Content C 0.25% • Tensile Strength RM (MPa*): 650 • Hardness (HB) or HRC: 220 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 33 | 25 | 40 | |||||||||||

| 108 | 82 | 131 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 20 | 15 | 25 | |||||||||||

| 65 | 49 | 82 | ||||||||||||||

| P3 • Medium- and High-Plain Carbon Steels, Low-Alloyed • Content C | ||||||||||||||||

| Through Holes | T620 | KP6525 | 28 | 20 | 35 | |||||||||||

| 92 | 66 | 115 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 17 | 12 | 21 | |||||||||||

| 55 | 59 | 69 | ||||||||||||||

| P5 • Ferritic, Martensitic, and PH Stainless Steels • Content C= 0-0.4% • Tensile Strength RM (MPa*): 600–850 • Hardness (HB) HRC: 330 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 18 | 10 | 25 | |||||||||||

| 59 | 33 | 82 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 11 | 6 | 15 | |||||||||||

| 35 | 20 | 49 | ||||||||||||||

| P6 • High-Strength Ferritic, Martensitic, and PH Stainless Steels • Content C=0.1-0.6% • Tensile Strength RM (MPa*): 900-1350 • Hardness (HB) HRC: 350–450 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 10 | 5 | 15 | |||||||||||

| 33 | 16 | 49 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 6 | 3 | 9 | |||||||||||

| 20 | 10 | 30 | ||||||||||||||

| M1 • Austenitic Stainless Steel • Content C=0.05-0.15% • Tensile Strength RM (MPa*): 650 • Hardness (HB) or HRC: 130-200 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| M2 • High-Strength Austenitic Stainless and Cast Stainless Steels • Content C=0.05-0.15% • Tensile Strength RM (MPa*): 500 - 700 • Hardness (HB) or HRC: 150-230 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| M3 • Duplex Steel • Content C=0.05-0.2 % • Tensile Strength RM (MPa*): 900 • Hardness (HB) HRC: 135-275 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| K1 • Cast and Low-Strength Ductile Irons • Tensile Strength RM (MPa*): 150-400 • Hardness (HB) or HRC: 120-290 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 45 | 30 | 60 | |||||||||||

| 148 | 98 | 197 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 27 | 18 | 36 | |||||||||||

| 90 | 59 | 118 | ||||||||||||||

| K2 • Low- and Medium-Strength CGI and Ductile Irons • Tensile Strength RM (MPa*): 400-600 • Hardness (HB) or HRC: 130-260 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 38 | 25 | 50 | |||||||||||

| 125 | 82 | 164 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 23 | 15 | 30 | |||||||||||

| 75 | 49 | 98 | ||||||||||||||

| K3 • High-Strength Ductile and Austempered Ductile Iron • Tensile Strength RM (MPa*): 600-900 • Hardness (HB) or HRC: 180-350 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 30 | 20 | 40 | |||||||||||

| 98 | 66 | 131 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 18 | 12 | 25 | |||||||||||

| 59 | 39 | 82 | ||||||||||||||

Tolerans

Tolerans

| Şaft toleransı | |

| D | Tolerans h6 + / - |

| 12 | +0, -0,011 |

| 20 | +0, -0,013 |

| 32 | +0, -0,016 |

DIN 371

| D1 | Hatve | D | L | L3* | L2 | L5 | S10 |

| M3 | 0,5 | 3,5 | 56 | 11 | 18 | 6 | 2,7 |

| M3.5 | 0,6 | 4 | 56 | 12 | 20 | 6 | 3 |

| M4 | 0,7 | 4,5 | 63 | 13 | 21 | 6 | 3,4 |

| M4.5 | 0,75 | 6 | 70 | 16 | 25 | 8 | 4,9 |

| M5 | 0,8 | 6 | 70 | 16 | 25 | 8 | 4,9 |

| M6 | 1 | 6 | 80 | 19 | 30 | 8 | 4,9 |

| M7 | 1 | 7 | 80 | 19 | 30 | 8 | 5,5 |

| M8 | 0,75 | 8 | 80 | 18 | 30 | 9 | 6,2 |

| M8 | 1,25 | 8 | 90 | 22 | 35 | 9 | 6,2 |

| M9 | 0,75 | 9 | 80 | 18 | 30 | 10 | 7 |

| M9 | 1,25 | 9 | 90 | 22 | 35 | 10 | 7 |

| M10 | 1 | 10 | 90 | 20 | 35 | 11 | 8 |

| M10 | 1,5 | 10 | 100 | 24 | 39 | 11 | 8 |

DIN 374

| Hatve | |||||||

| D1 | Minimum | Maksimum | D | L | L3* | L5 | S10 |

| M8 | 0,2 | 0,75 | 6 | 80 | 18 | 8 | 4,9 |

| M8 | 1 | 6 | 90 | 22 | 8 | 4,9 | |

| M9 | 0,2 | 0,75 | 7 | 80 | 18 | 8 | 5,5 |

| M9 | 1 | 7 | 90 | 22 | 8 | 5,5 | |

| M10 | 0,2 | 1 | 7 | 90 | 20 | 8 | 5,5 |

| M10 | 1,25 | 7 | 100 | 24 | 8 | 5,5 | |

| M11 | 0,35 | 1 | 8 | 90 | 20 | 9 | 6,2 |

| M12 | 0,35 | 1,5 | 9 | 100 | 22 | 10 | 7 |

| M14 | 0,35 | 1,5 | 11 | 100 | 22 | 12 | 9 |

| M16 | 0,35 | 1,5 | 12 | 100 | 22 | 12 | 9 |

| M16 | 2 | 12 | 110 | 32 | 12 | 9 | |

| M18 | 0,35 | 1,5 | 14 | 110 | 25 | 14 | 11 |

| M18 | 2 | 14 | 125 | 34 | 14 | 11 | |

| M20 | 0,35 | 1,5 | 16 | 125 | 25 | 15 | 12 |

| M20 | 2 | 16 | 140 | 34 | 15 | 12 | |

| M22 | 0,35 | 1,5 | 18 | 125 | 25 | 17 | 14,5 |

| M22 | 2 | 18 | 140 | 34 | 17 | 14,5 | |

| M24 | 0,35 | 2 | 18 | 140 | 28 | 17 | 14,5 |

| M27 | 0,35 | 2 | 20 | 140 | 28 | 19 | 16 |

| M30 | 0,35 | 2 | 22 | 150 | 28 | 21 | 18 |

| M30 | 3 | 22 | 180 | 45 | 21 | 18 | |

DIN 376

| D1 | Hatve | D | L | L3* | L5 | S10 |

| M8 | 1,25 | 6 | 90 | 22 | 8 | 4,9 |

| M9 | 1,25 | 7 | 90 | 22 | 8 | 5,5 |

| M10 | 1,5 | 7 | 100 | 24 | 8 | 5,5 |

| M11 | 1,5 | 8 | 100 | 24 | 9 | 6,2 |

| M12 | 1,75 | 9 | 110 | 28 | 10 | 7 |

| M14 | 2 | 11 | 110 | 30 | 12 | 9 |

| M16 | 2 | 12 | 110 | 32 | 12 | 9 |

| M18 | 2,5 | 14 | 125 | 34 | 14 | 11 |

| M20 | 2,5 | 16 | 140 | 34 | 15 | 12 |

| M22 | 2,5 | 18 | 140 | 34 | 17 | 14,5 |

| M24 | 3 | 18 | 160 | 38 | 17 | 14,5 |

| M27 | 3 | 20 | 160 | 38 | 19 | 16 |

| M30 | 3,5 | 22 | 180 | 45 | 21 | 18 |

| M33 | 3,5 | 25 | 180 | 50 | 23 | 20 |

| M36 | 4 | 28 | 200 | 56 | 25 | 22 |

| M39 | 4 | 32 | 200 | 60 | 27 | 24 |

| M42 | 4,5 | 32 | 200 | 60 | 27 | 24 |

| M45 | 4,5 | 36 | 220 | 65 | 32 | 29 |

JIS Tip 3 Metrik kaba

| D1 | Hatve | D | L | L3 | L5 | S10 |

| M8 | 1,25 | 6,2 | 70 | 22 | 8 | 5 |

| M9 | 1,25 | 7 | 72 | 22 | 8 | 5,5 |

| M10 | 1,5 | 7 | 75 | 24 | 8 | 5,5 |

| M11 | 1,5 | 8 | 80 | 25 | 9 | 6 |

| M12 | 1,75 | 8,5 | 82 | 29 | 9 | 6,5 |

| M14 | 2 | 10,5 | 88 | 30 | 11 | 8 |

| M16 | 2 | 12,5 | 95 | 32 | 13 | 10 |

| M18 | 2,5 | 14 | 100 | 37 | 14 | 11 |

| M20 | 2,5 | 15 | 105 | 37 | 15 | 12 |

| M22 | 2,5 | 17 | 115 | 38 | 16 | 13 |

| M24 | 3 | 19 | 120 | 45 | 18 | 15 |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data