Producto similar a:

Plaquitas para Fix-Perfect™ • SPHX12-PC-GP

Plaquitas intercambiables • SPHX1205... • Acabado

Número de material1505400

Referencia ISOSPHX1205PCTR-GP1WBKReferencia ANSISPHX1205PCTR-GP1WBK

- K Fundición

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Comentarios

- Preguntas y Respuestas

| Número de material | 1505400 |

| Referencia ISO | SPHX1205PCTR-GP1WBK |

| Referencia ANSI | SPHX1205PCTR-GP1WBK |

| Calidad | KY3500 |

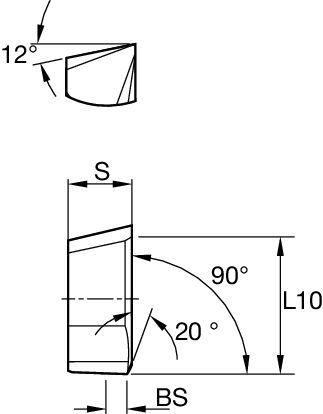

| Longitud de filo de corte de plaquita [L10] | 11 mm |

| Longitud de filo de corte de plaquita [L10] | 0.4331 in |

| Grosor de plaquita [S] | 5.5 mm |

| Grosor de plaquita [S] | 0.2165 in |

| Longitud de cara de esquina [BS] | 2 mm |

| Longitud de cara de esquina [BS] | 0.0787 in |

| Grosor medio de las virutas [HM] | 0.24 mm |

| Grosor medio de las virutas [HM] | 0.0094 in |

| Filos de corte por plaquita | 1 |

Materiales de la pieza de trabajo

- Fundición

Grades

KY3500

Un materiale da taglio ceramico a base di microgranuli di Si3N4 da utilizzare principalmente nella lavorazione leggera e generale della ghisa grigia e della ghisa duttile ferritica. Si consiglia la lavorazione a secco.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data