Producto similar a:

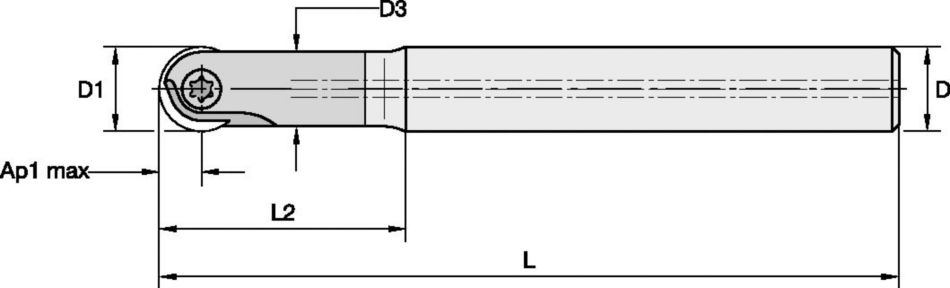

KDMB • Ball Nose Finisher • Necked End Mills • Carbide • Inch

Indexable Ball Nose Finisher

Número de material2879412

Referencia ISOKDMB1000R906A100HNCReferencia ANSIKDMB1000R906A100HNC

- P Acero

- M Acero inoxidable

- K Fundición

- N Materiales no ferrosos

- S Aleaciones de alta temperatura

- H Materiales endurecidos

Rectificado en rampa: Material en bruto

Ranurado: Nariz de bola

Fresado lateral/Fresado en escuadra: Nariz de bola

Perfilado 3D

Mango — Liso cilíndrico

Mecanizado de alojamientos

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Piezas compatibles Lado de la pieza

- Piezas de recambio

- Comentarios

- Preguntas y Respuestas

| Número de material | 2879412 |

| Referencia ISO | KDMB1000R906A100HNC |

| Referencia ANSI | KDMB1000R906A100HNC |

| Diámetro de corte efectivo [D1] | 25.4 mm |

| Diámetro de corte efectivo [D1] | 1 in |

| Adaptador/Mango/Diá int [D] | 25.4 mm |

| Adaptador/Mango/Diá int [D] | 1 in |

| Diámetro de cuello [D3] | 22.61 mm |

| Diámetro de cuello [D3] | .89 in |

| Longitud total [L] | 210 mm |

| Longitud total [L] | 8.27 in |

| Longitud de cabeza [L2] | 89.9 mm |

| Longitud de cabeza [L2] | 3.539 in |

| 1.ª profundidad de corte máxima [AP1MAX] | 12.7 mm |

| 1.ª profundidad de corte máxima [AP1MAX] | .5 in |

| Número de plaquitas | 1 |

| Número de canales [Z] | 2 |

| Suministro de refrigerante | Y |

| Ángulo de vaciado máximo | 3 |

| RPM máx. | 30000 |

| Calibre de plaquita | KDMB1000. |

| Peso en libras | 2.01 |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Materiales no ferrosos

- Aleaciones de alta temperatura

- Materiales endurecidos

Uses and application

Rectificado en rampa: Material en bruto

Ranurado: Nariz de bola

Fresado lateral/Fresado en escuadra: Nariz de bola

Perfilado 3D

Mango — Liso cilíndrico

Mecanizado de alojamientos

Features and benefits

- Available diameters: .250–1.250".

- Ball nose finishers for 3D milling applications.

- Suitable for roughing and finishing operations.

- High precision and runout accuracy.

- Can be used with heat shrink technology, h6 shank tolerance.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Insert Selection

KDMB Ball Nose Platform • .250"

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC515M | .E..GP | KC515M | – | – |

KDMB Ball Nose Platform • .312"

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .375"

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .500"

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • .625"

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .750"

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • 1.00"

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • 1.25"

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | ||

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

Feeds

KDMB Ball Nose • .250"

| Diámetro de trabajo (Dw) en profundidad de corte axial (ap) | ||||

| D1 máx | 0.125 | 0.050 | 0.025 | 0.013 |

| 0.250 | 0.250 | 0.200 | 0.150 | 0.109 |

At .125 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .050 Axial Depth of Cut (ap)

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

At .025 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

At .013 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..LD |

| .E..GP | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..GP |

KDMB Ball Nose • .312"

| Diámetro de trabajo (Dw) en profundidad de corte axial (ap) | ||||

| D1 máx | 0.156 | 0.047 | 0.031 | 0.016 |

| 0.313 | 0.313 | 0.223 | 0.188 | 0.136 |

At .156 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .047 Axial Depth of Cut (ap)

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

At .031 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

At .016 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

KDMB Ball Nose • .375"

| Diámetro de trabajo (Dw) en profundidad de corte axial (ap) | ||||

| D1 máx | 0.188 | 0.056 | 0.038 | 0.019 |

| 0.375 | 0.375 | 0.268 | 0.225 | 0.163 |

At .188 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .056 Axial Depth of Cut (ap)

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

At .038 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

At .019 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

KDMB Ball Nose • .500"

| Diámetro de trabajo (Dw) en profundidad de corte axial (ap) | ||||

| D1 máx | 0.250 | 0.075 | 0.050 | 0.025 |

| 0.500 | 0.500 | 0.357 | 0.300 | 0.218 |

At .250 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .075 Axial Depth of Cut (ap)

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

At .050 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

At .025 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • .625"

| Diámetro de trabajo (Dw) en profundidad de corte axial (ap) | ||||

| D1 máx | 0.313 | 0.094 | 0.063 | 0.031 |

| 0.625 | 0.625 | 0.446 | 0.375 | 0.272 |

At .313 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .094 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .063 Axial Depth of Cut (ap)

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

At .031 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • .750"

| Diámetro de trabajo (Dw) en profundidad de corte axial (ap) | ||||

| D1 máx | 0.375 | 0.113 | 0.075 | 0.038 |

| 0.750 | 0.750 | 0.536 | 0.450 | 0.327 |

At .375 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .113 Axial Depth of Cut (ap)

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

At .075 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .038 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • 1.00"

| Diámetro de trabajo (Dw) en profundidad de corte axial (ap) | ||||

| D1 máx | 0.500 | 0.150 | 0.100 | 0.050 |

| 1.000 | 1.000 | 0.714 | 0.600 | 0.436 |

At .500 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .150 Axial Depth of Cut (ap)

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

At .100 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .050 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • 1.25"

| Diámetro de trabajo (Dw) en profundidad de corte axial (ap) | ||||

| D1 máx | 0.625 | 0.188 | 0.125 | 0.063 |

| 1.250 | 1.250 | 0.893 | 0.750 | 0.545 |

At .625 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .188 Axial Depth of Cut (ap)

| Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo |

At .125 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

At .063 Axial Depth of Cut (ap)

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | Geometría de plaquita | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

Speeds

Recommended Starting Speeds [SFM]

| Grupo de materiales | K115M | KC505M | KC515M | KC530M | |||||||||

| P | 1 | – | – | – | – | – | – | 1080 | 960 | 840 | 900 | 780 | 660 |

| 2 | – | – | – | – | – | – | 1020 | 900 | 780 | 780 | 660 | 540 | |

| 3 | – | – | – | – | – | – | 900 | 780 | 660 | 660 | 600 | 540 | |

| 4 | – | – | – | 1180 | 860 | 710 | 780 | 660 | 540 | 600 | 540 | 480 | |

| 5 | – | – | – | 1180 | 860 | 710 | 660 | 540 | 420 | 540 | 480 | 420 | |

| 6 | – | – | – | 1140 | 780 | 620 | 540 | 420 | 360 | 420 | 360 | 300 | |

| M | 1 | – | – | – | – | – | – | 1080 | 900 | 780 | 900 | 720 | 600 |

| 2 | – | – | – | – | – | – | 900 | 720 | 540 | 600 | 480 | 420 | |

| 3 | – | – | – | – | – | – | 720 | 600 | 480 | 480 | 420 | 360 | |

| K | 1 | 720 | 600 | 480 | – | – | – | 1440 | 1080 | 720 | – | – | – |

| 2 | 600 | 480 | 360 | – | – | – | 1080 | 840 | 600 | – | – | – | |

| 3 | 360 | 300 | 240 | – | – | – | 480 | 360 | 240 | – | – | – | |

| N | 1–2 | 1440 | 1080 | 720 | – | – | – | – | – | – | – | – | – |

| 3 | 960 | 720 | 600 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | 300 | 230 | 160 | – | – | – | – | – | – | 260 | 200 | 170 | |

| H | 1 | – | – | – | 860 | 670 | 550 | 550 | 400 | 310 | – | – | – |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use