Producto similar a:

KOR5™ DS • Radiused • 5 Flutes • 5 x D • Weldon® Shank • Inch

KOR5™ DS Solid Carbide End Mill for Dynamic Milling of Steel and Stainless Steel

Número de material6764476

Referencia ISOKOR5RA0250L125HBR030Referencia ANSIKOR5RA0250L125HBR030

- P Acero

- M Acero inoxidable

- K Fundición

- S Aleaciones de alta temperatura

- H Materiales endurecidos

Trochoidal Milling

Rectificado en rampa: 5°

Fresado lateral/Fresado en escuadra: Placa cuadrada

Dimensiones de la herramienta: Configuración del canal: 5

Mango — Weldon cilíndrico

Ángulo de la hélice: 40°

Estilo de esquina: Radio de esquina

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Vídeos

- Comentarios

- Preguntas y Respuestas

| Número de material | 6764476 |

| Referencia ISO | KOR5RA0250L125HBR030 |

| Referencia ANSI | KOR5RA0250L125HBR030 |

| Calidad | KC643M |

| Tipo de adaptador Lateral de máquina | Weldon |

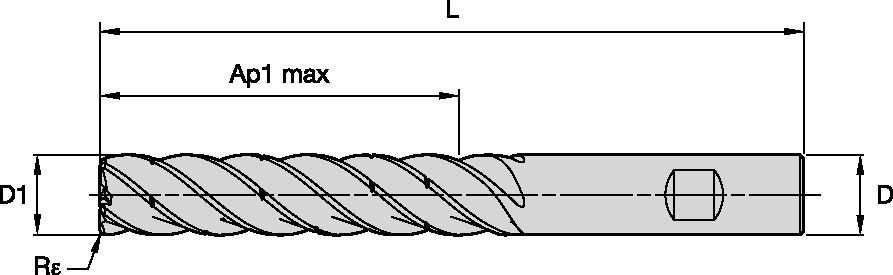

| Radio de esquina [Re] | 0.762 mm |

| Radio de esquina [Re] | .03 in |

| Número de canales [Z] | 5 |

| Diámetro de corte efectivo [D1] | 6.35 mm |

| Diámetro de corte efectivo [D1] | .25 in |

| Adaptador/Mango/Diá int [D] | 6.35 mm |

| Adaptador/Mango/Diá int [D] | .25 in |

| 1.ª profundidad de corte máxima [AP1MAX] | 31.75 mm |

| 1.ª profundidad de corte máxima [AP1MAX] | 1.25 in |

| Longitud total [L] | 76.2 mm |

| Longitud total [L] | 3 in |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Aleaciones de alta temperatura

- Materiales endurecidos

Uses and application

Trochoidal Milling

Rectificado en rampa: 5°

Fresado lateral/Fresado en escuadra: Placa cuadrada

Dimensiones de la herramienta: Configuración del canal: 5

Mango — Weldon cilíndrico

Ángulo de la hélice: 40°

Estilo de esquina: Radio de esquina

Grades

KC643M

Calidad de grano fino recubierta con multicapa de PVD (AlTiN). KC643M™ es un recubrimiento PVD duro y muy fino especialmente adecuado para cortar acero, fundición, acero inoxidable (húmedo) y titanio (húmedo). Esta calidad se puede utilizar para materiales con dureza hasta 52 HRC.

Features and benefits

- Designed for trochoidal milling with low radial engagement and full length of cut.

- With chip deformers for ideal chip evacuation at high surface quality.

- Proprietary flute form reduces vibrations and improves tool life.

- Helix angle tailored to minimize vibration and optimize tool life.

- Front end geometry designed for maximum tool life in helical and ramping operations.

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

TechnicalInfo

KOR5™ DS • 5 Flutes • 5 x D • Adjustment factor table for feed calculation • Inch

| Ae/D1 | 0.50% | 1.00% | 1.50% | 2.00% | 4.00% | 5.00% | |

| Speed factor | Kv | 2.00 | 1.97 | 1.93 | 1.38 | 1.03 | 1.00 |

| Feed factor | KFz | 1.27 | 1.18 | 1.14 | 1.09 | 1.05 | 1.00 |

Datos de aplicación

KOR5™ DS • 5 Flutes • 5 x D • Application Data • Inch

| Grupo de materiales |  |  | |||||||||||

| Fresado lateral (A) | Recommended feed per tooth (IPT = inch/th) for side milling (A). | ||||||||||||

| A | KC643M | D1 | |||||||||||

| Velocidad de corte | frac. | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 1 | ||||||

| ap | ae | Mín | Máx. | dec. | .2500 | .3750 | .5000 | .6250 | .7500 | 1.0000 | |||

| P | 0 | 5 x D | 0.05 x D | 500 | – | 1770 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 |

| 1 | 5 x D | 0.05 x D | 500 | – | 1770 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 | |

| 2 | 5 x D | 0.05 x D | 460 | – | 1680 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 | |

| 3 | 5 x D | 0.05 x D | 400 | – | 1420 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 | |

| 4 | 5 x D | 0.05 x D | 300 | – | 1330 | IPT | .0022 | .0033 | .0041 | .0048 | .0054 | .0062 | |

| 5 | 5 x D | 0.05 x D | 200 | – | 890 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| 6 | 5 x D | 0.05 x D | 170 | – | 660 | IPT | .0017 | .0024 | .0031 | .0036 | .0040 | .0045 | |

| M | 1 | 5 x D | 0.05 x D | 300 | – | 1020 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 |

| 2 | 5 x D | 0.05 x D | 200 | – | 710 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| 3 | 5 x D | 0.05 x D | 200 | – | 620 | IPT | .0017 | .0024 | .0031 | .0036 | .0040 | .0045 | |

| K | 1 | 5 x D | 0.05 x D | 400 | – | 1330 | IPT | .0029 | .0044 | .0054 | .0063 | .0070 | .0078 |

| 2 | 5 x D | 0.05 x D | 370 | – | 1240 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 | |

| 3 | 5 x D | 0.05 x D | 370 | – | 1150 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| S | 1 | 5 x D | 0.05 x D | 170 | – | 800 | IPT | .0024 | .0037 | .0046 | .0055 | .0062 | .0072 |

| 2 | 5 x D | 0.05 x D | 80 | – | 710 | IPT | .0020 | .0029 | .0037 | .0044 | .0049 | .0058 | |

| 3 | 5 x D | 0.05 x D | 80 | – | 350 | IPT | .0013 | .0019 | .0025 | .0029 | .0033 | .0039 | |

| 4 | 5 x D | 0.05 x D | 170 | – | 530 | IPT | .0017 | .0027 | .0034 | .0040 | .0045 | .0053 | |

| H | 1 | 5 x D | 0.05 x D | 270 | – | 1240 | IPT | .0022 | .0033 | .0041 | .0048 | .0054 | .0062 |

| 2 | 5 x D | 0.05 x D | 230 | – | 1060 | IPT | .0017 | .0024 | .0031 | .0036 | .0040 | .0045 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use

KOR™5DS

KOR™ Series End Mills: Solid End Mills for Dynamic Milling