Product Similar To:

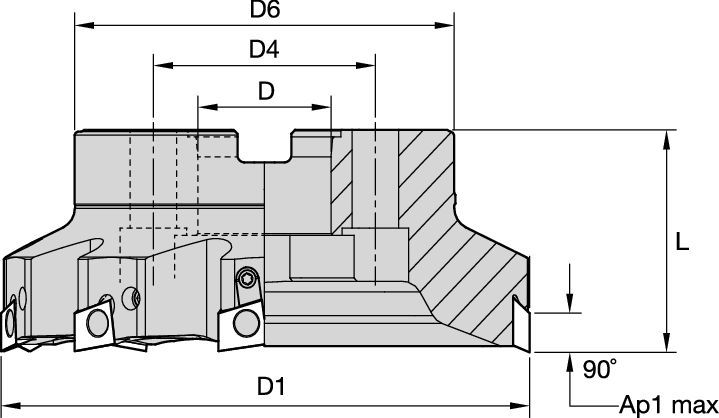

Fix-Perfect™ • Aluminum • Shell Mills • PM Line • Inch

Shell Mills • PM Line

Material Number1805716

ISO Catalog ID100B08RP90BG15C2WUPMANSI Catalog ID100B08RP90BG15C2WUPM

- P Steel

- K Cast Iron

- N Non-Ferrous

- H Hardened Materials

Face Milling

Side Milling/Shoulder Milling: Square End

Milling - Through Coolant

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 1805716 |

| ISO Catalog ID | 100B08RP90BG15C2WUPM |

| ANSI Catalog ID | 100B08RP90BG15C2WUPM |

| [D1] Effective Cutting Diameter | 101.6 mm |

| [D1] Effective Cutting Diameter | 4 in |

| [D] Adapter / Shank / Bore Diameter | 31.75 mm |

| [D] Adapter / Shank / Bore Diameter | 1.25 in |

| [D6] Hub Diameter | 69.2 mm |

| [D6] Hub Diameter | 2.724 in |

| [L] Overall Length | 44.45 mm |

| [L] Overall Length | 1.75 in |

| [AP1MAX] 1st Maximum Cutting Depth | 9.52 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .375 in |

| Number of Inserts | 8 |

| Number of Adjustable Inserts | 2 |

| Weight Pounds | 3.22 |

| Max RPM | 12500 |

Workpiece Materials

- Steel

- Cast Iron

- Non-Ferrous

- Hardened Materials

Uses and application

Face Milling

Side Milling/Shoulder Milling: Square End

Milling - Through Coolant

Milling - Side and Face

Features and benefits

- High-speed Machining.

- Produces excellent surface finish and flatness.

- Fixed and adjustable pockets.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | (Sert geometri) | ||||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | BGHX… | K110M | BGHX… | KC510M | BGHX… | KD1415 |

| N3 | BGHX… | K110M | BGHX… | KD1410 | BGHX… | KD1410 |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

Feeds

Recommended Starting Feeds [IPT]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40 | ||||||||||||

| BGHX… | .005 | .014 | .023 | .003 | .010 | .017 | .003 | .008 | .013 | .002 | .007 | .011 | .002 | .006 | .010 | BGHX… |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

Speeds

Recommended Starting Speeds [SFM]

| Malzeme grubu | K110M | KC510M | KD1410 | KD1415 | |||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1–2 | 1650 | 1550 | 1475 | 2100 | 1870 | 1720 | 13150 | 11500 | 9800 | 13150 | 11500 | 9800 |

| 3 | 1350 | 1200 | 1050 | 1900 | 1750 | 1600 | 5250 | 4900 | 4600 | 5250 | 4900 | 4600 | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use