Chips From the Real World – HARVI™ I TE

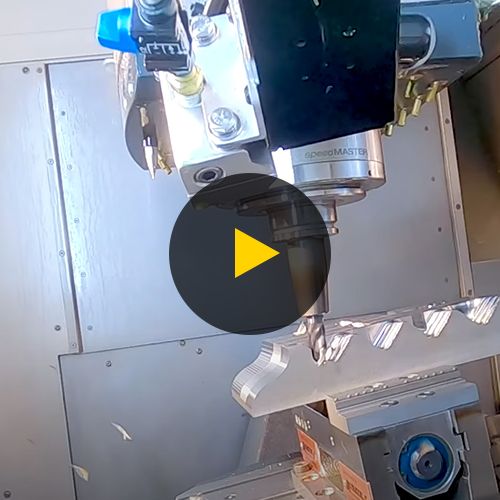

Aluro CNC needed to machine 19 holes in a thin steel workpiece each 35 millimeters in diameter. Their process had been to drill a 34-millimeter hole with a competitor's drill which made a horrible sound, and then to finish the final millimeter with another competitor's end mill. Aluro turned to the new HARVI I TE end mill to eliminate that tool change. With the HARVI I TE the shop was able to plunge at a 30-degree angle creating a 21-millimeter hole, and then use circular interpolation to open up the rest of the hole to 35 millimeters. They were able to complete the task with no visible wear on the cutting edges of HARVI I TE. The HARVI I TE was not only able to save two minutes in tool change time, but also brought peace back to their shop floor.