Product Similar To:

Beyond™ Evolution™ • Cut-Off Insert • CF Geometry • Metric

Grooving, and Cut-Off • Carbide insert

Material Number6017499

ISO Catalog IDEC014M1BN00CF01ANSI Catalog IDEC014M1BN00CF01

- P Steel

- M Stainless Steel

- S High-Temp Alloys

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 6017499 |

| ISO Catalog ID | EC014M1BN00CF01 |

| ANSI Catalog ID | EC014M1BN00CF01 |

| Grade | KCM35B |

| Insert Size | 1B |

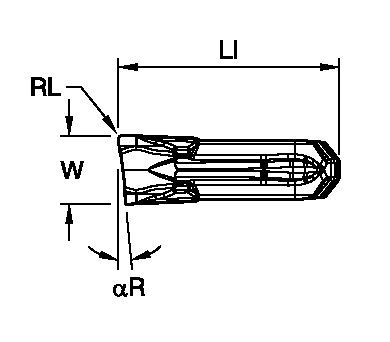

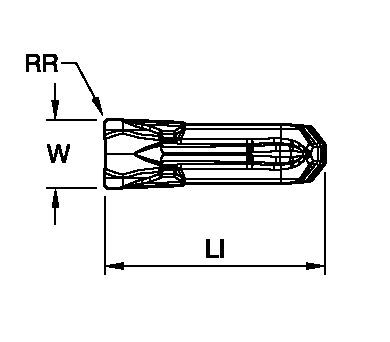

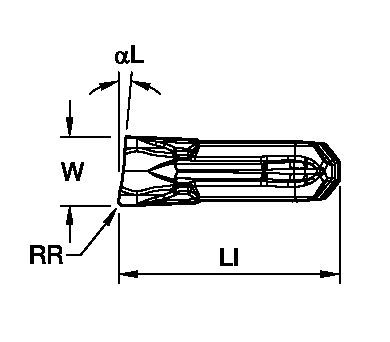

| [W] Cutting Width | 1.4 mm |

| [W] Cutting Width | .055 in |

| Cuttg Width (+/-) Tolerance | 0.05 mm |

| Cuttg Width (+/-) Tolerance | .002 in |

| [LI] Insert Length | 9 mm |

| [LI] Insert Length | .355 in |

| [RR] Corner Radius | 0.15 mm |

| [RR] Corner Radius | .006 in |

| [RL] Corner Radius | 0.15 mm |

| [RL] Corner Radius | .006 in |

Workpiece Materials

- Steel

- Stainless Steel

- High-Temp Alloys

Grades

KCM35B

Composition: A multilayer TiN-MT-TiCN-Al2O3-TiOCN CVD coating over a super-tough substrate.

Application: The KCM35 grade is engineered to take on the most brutal cast stainless steel machining applications. The substrate withstands heavy interruptions, while the coating provides the wear resistance needed for long tool life. The polished surface resists edge build-up, even at slow cutting speeds. KCM35 grade is available in insert sizes and geometries appropriate for heavy feeds and large depths of cut.

Features and benefits

- Positive chipbreaker lowers cutting forces

- First choice for steel

- Excellent surface finish

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

I have read and accepted the Terms & Conditions of use