Product Similar To:

KSSM™ 12 • Ceramic Insert • SDCW-GN • Heavy Machining of Cast Iron

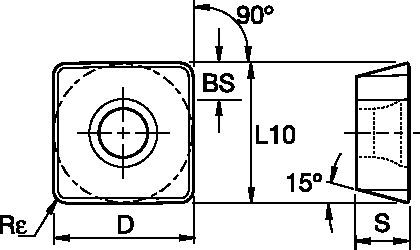

Shoulder milling insert with four cutting edges, precision ground.

Material Number1597228

ISO Catalog IDSDCW120412PDSRGNANSI Catalog IDSDCW433PDSR8GN

- K Cast Iron

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Material Number | 1597228 |

| ISO Catalog ID | SDCW120412PDSRGN |

| ANSI Catalog ID | SDCW433PDSR8GN |

| Grade | KY3500 |

| [D] Insert IC Size | 12.7 mm |

| [D] Insert IC Size | 0.5 in |

| [S] Insert Thickness | 4.76 mm |

| [S] Insert Thickness | 0.188 in |

| [L10] Insert Cutting Edge Length | 12.7 mm |

| [L10] Insert Cutting Edge Length | 0.5 in |

| [BS] Corner Facet Length | 1.86 mm |

| [BS] Corner Facet Length | 0.073 in |

| [Rε] Corner Radius | 1.19 mm |

| [Rε] Corner Radius | 0.047 in |

| Average Chip Thickness [HM] | 0.159 mm |

| Average Chip Thickness [HM] | 0.0063 in |

| Cutting Edges per Insert | 4 |

Workpiece Materials

- Cast Iron

Grades

KY3500

A ceramic cutting material based on micro-grain Si3N4 primarily for use in light to general machining of gray cast iron and ferritic ductile cast iron. Dry machining is recommended.

Features and benefits

- Single sided insert for lower power requirements.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Insert Selection

Insert Selection Guide

| KSSM™ 12 • Insert Selection Guide | ||||||

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..LD2 | KCPM40 | .E..GB2 | KCPM40 | .S..GB2 | KCPM40 |

| P3–P4 | .E..LD2 | KCPM40 | .E..GB2 | KCPK30 | .S..GB2 | KCPK30 |

| P5–P6 | .E..LD2 | KC725M | .E..GB2 | KC725M | .S..GB2 | KC725M |

| M1–M2 | .E..LD2 | KCSM40 | .E..GB2 | KCSM40 | .S..GB2 | KCSM40 |

| M3 | .E..LD2 | KCPM40 | .E..GB2 | KCPM40 | .S..GB2 | KCPM40 |

| K1–K2 | .E..LD2 | KCK20B | .E..GB2 | KCK15 | .S..GN | KY3500 |

| K3 | .E..LD2 | KCK20B | .E..GB2 | KCK20B | .S..GB2 | KCK20B |

| N1–N2 | .F..LE | KC410M | .F..LE | KC410M | .F..LE | KC410M |

| N3 | .F..LE | KC410M | .F..LE | KC410M | .F..LE | KC410M |

| S1–S2 | .E..LD2 | KC725M | .E..GB2 | KC725M | .S..GB2 | KC725M |

| S3 | .E..LD2 | KCSM40 | .E..GB2 | KCSM40 | .S..GB2 | KCSM40 |

| S4 | .E..LD2 | KCSM40 | .E..GB2 | KCSM40 | .S..GB2 | KCSM40 |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use