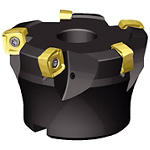

7793 High-Feed • IC 12 • Stellram

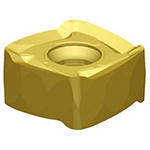

The 7793 double-sided insert and high-feed milling cutter system provide cost-effective machining and maximum efficiency for your applications. The face milling system features double-sided inserts with eight cutting edges. The unique geometrical design concept and insert positioning are ideal for achieving metal removal at high rates. The 7793 series provides superior wall and floor surface finish capabilities through roughing operations in comparison with other high-feed solutions. These cutters are particularly qualified to machine unalloyed steels, alloyed steels, tool steels, stainless steels, high-temperature alloys, and titanium when utilizing the GU52 double-sided insert Due to their positive geometry design and reinforced edge, these inserts provide a smooth cutting action and longer tool life in all challenging machining applications.

- P Steel (22)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(22)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(22)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(22)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(22)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(22)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(22)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(22)

- M Stainless Steel (22)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(22)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(22)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(22)

- S High-Temp Alloys (22)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(22)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(22)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(22)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(22)

Face Milling (20)

Profile Milling (20)

Slot Milling (20)

Slot Side (20)

- 1.25 in(1)

- 1.26 in(1)

- 1.366 in(2)

- 1.401 in(1)

- 1.5 in(2)

- 1.875 in(2)

- 1.895 in(1)

- 1.901 in(1)

- 2.0 in(1)

- 2.338 in(1)

- 2.395 in(1)

- 2.543 in(1)

- 3.15 in(1)

- 3.383 in(1)

- 3.938 in(1)

- 4.313 in(1)

- 5.392 in(1)

- 31.75 mm(1)

- 32.0 mm(1)

- 34.7 mm(2)

- 35.551 mm(1)

- 38.1 mm(2)

- 47.625 mm(2)

- 48.125 mm(1)

- 48.25 mm(1)

- 50.801 mm(1)

- 59.375 mm(1)

- 60.825 mm(1)

- 64.601 mm(1)

- 80.0 mm(1)

- 85.926 mm(1)

- 100.0 mm(1)

- 109.551 mm(1)

- 136.951 mm(1)

- 50.0 mm(2)

- 50.801 mm(1)

- 62.575 mm(1)

- 63.0 mm(1)

- 63.5 mm(2)

- 76.2 mm(2)

- 80.0 mm(1)

- 101.351 mm(1)

- 125.0 mm(1)

- 152.4 mm(1)

- 1.969 in(2)

- 2.0 in(1)

- 2.464 in(1)

- 2.48 in(1)

- 2.5 in(2)

- 3.0 in(2)

- 3.15 in(1)

- 3.99 in(1)

- 4.921 in(1)

- 6.0 in(1)

- 2.176 mm(1)

- 2.225 mm(1)

- 2.5 mm(18)

- 0.087 in(1)

- 0.088 in(1)

- 0.098 in(18)

- 1.575 in(8)

- 1.693 in(1)

- 1.968 in(1)

- 1.969 in(5)

- 2.48 in(2)

- 2.755 in(2)

- 2.757 in(1)

- 40.0 mm(8)

- 43.0 mm(1)

- 49.975 mm(1)

- 50.0 mm(5)

- 63.0 mm(2)

- 69.976 mm(2)

- 70.0 mm(1)

- 15.0 (9)

- 15.137 (1)

- 16.0 (10)

- A-Socket Head Cap Screw (15)

- C-Bolt Circle (1)

- Screw-On Connection (1)

- Straight-Cylindrical (3)

- 10 (1)

- 2 (2)

- 3 (2)

- 4 (2)

- 5 (5)

- 6 (3)

- 7 (2)

- 8 (1)

- 9 (2)

- 1.575 in(8)

- 1.968 in(1)

- 1.969 in(5)

- 2.48 in(2)

- 2.598 in(1)

- 9.842 in(2)

- 9.843 in(1)

- 40.0 mm(8)

- 49.975 mm(1)

- 50.0 mm(5)

- 63.0 mm(2)

- 66.0 mm(1)

- 249.976 mm(2)

- 250.0 mm(1)

- SP6519 (21)

- X500 (21)

- R (20)

- 1.083 in(2)

- 1.158 in(1)

- 27.5 mm(2)

- 29.425 mm(1)

- S-SQUARE 90 (2)

- 12.701 mm(2)

- 0.5 in(2)

- 12.0 mm(2)

- 0.473 in(2)

- GU52 (2)

- H W (2)

- G (2)

- CYLINDRICAL (3)

- SCREW-ON (1)

- SHELL MILL (16)

- 19.05 mm(2)

- 22.0 mm(4)

- 25.401 mm(4)

- 27.0 mm(2)

- 29.0 mm(1)

- 31.75 mm(3)

- 32.0 mm(2)

- 38.1 mm(1)

- 40.0 mm(1)

- 0.75 in(2)

- 0.866 in(4)

- 1.0 in(4)

- 1.063 in(2)

- 1.143 in(1)

- 1.25 in(3)

- 1.26 in(2)

- 1.5 in(1)

- 1.575 in(1)