Produit similaire à:

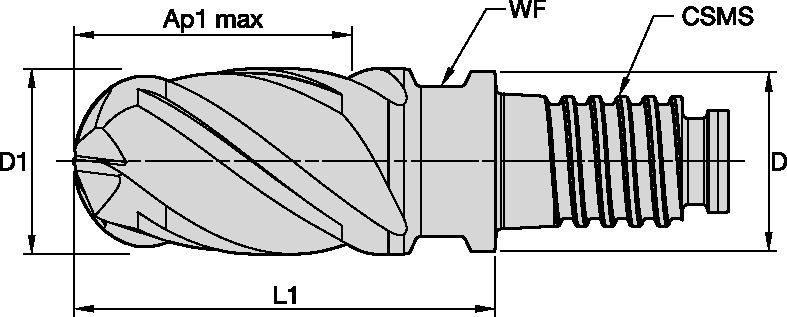

DUO-LOCK™ • HARVI™ I • Ball Nose • 4 Flutes • Inch

HARVI Ball Nose • UKBV • Asymmetrical Flute Spacing

Numéro de matériel6070995

Ref. ISO CatalogueUKBV1000Y4CNRef. ANSI CatalogueUKBV1000Y4CN

- P Acier

- M Acier inoxydable

- K Fonte

- S Alliages hautes températures

- H Matériaux trempés

Helix Angle: 37°/39°

Rainurage : Bout hémisphérique

Fraisage de côté/avec épaulement : Bout hémisphérique

Profilage 3D

Dimensions de l'outil : Configuration des goujures : 4

Corner Style: Ball Nose

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Numéro de matériel | 6070995 |

| Ref. ISO Catalogue | UKBV1000Y4CN |

| Ref. ANSI Catalogue | UKBV1000Y4CN |

| Nuance | KCPM15 |

| Style adaptateur du côté machine | DUO-LOCK |

| [D] Adaptateur / Queue / Diamètre d’alésage | 24.4 mm |

| [D] Adaptateur / Queue / Diamètre d’alésage | .9606 in |

| [AP1MAX] 1re profondeur de coupe maximale | 38.1 mm |

| [AP1MAX] 1re profondeur de coupe maximale | 1.5 in |

| [L1] Longueur de référence | 57.2 mm |

| [L1] Longueur de référence | 2.252 in |

| [CSMS] Dimension du système Côté machine | DL25 |

| [WF] Largeur du méplat | 21 mm |

| [WF] Largeur du méplat | .8268 in |

| [Z] Nombre de goujures | 4 |

| [D1] Diamètre effectif de coupe | 25.4 mm |

| [D1] Diamètre effectif de coupe | 1 in |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Fonte

- Alliages hautes températures

- Matériaux trempés

Uses and application

Helix Angle: 37°/39°

Rainurage : Bout hémisphérique

Fraisage de côté/avec épaulement : Bout hémisphérique

Profilage 3D

Dimensions de l'outil : Configuration des goujures : 4

Corner Style: Ball Nose

Features and benefits

- Asymmetrical flute spacing and variable helix configuration minimize chatter and harmonics for smoother machining.

- Center cutting.

- Single tool for both roughing and finishing, reducing setups.

- Standard items listed. Additional styles and coatings made-to-order.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Tolérance

| Parmak freze toleransları | |

| D1 | Tolerans e8 |

| 13/32 | -0,00126"/-0,00232" |

| 23/32 | -0,00157"/-0,00287" |

| -0,00197''/-0,00350'' | |

Données d'application

HARVI Ball Nose • UKBV • Asymmetrical Flute Spacing • Roughing • Finishing

| Malzeme grubu |  |  |  | |||||||||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | Kısa | Orta | Uzun | Kenar frezeleme (A) için önerilen diş başına ilerleme (IPT = inç/diş). Kanal açma (B) için IPT %20 azaltılır. | ||||||||||||||||

| A | B | Uygun adaptör | D1 | |||||||||||||||||

| KCPM15 | KCPM15 | KCPM15 | ||||||||||||||||||

| Kesme hızı | Kesme hızı | Kesme hızı | frac. | 3/8 | 1/2 | 5/8 | 3/4 | 1 | 1 1/4 | |||||||||||

| ap | ae | ap | Min. | Maks. | Min. | Maks. | Min. | Maks. | dec. | .3750 | .5000 | .6250 | .7500 | 1.2500 | 1.2500 | |||||

| P | 0 | 1.25 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 |

| 1 | 1.25 x D | 0.5 x D | 1 x D | 490 | – | 660 | 441 | – | 594 | 441 | – | 594 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 2 | 1.25 x D | 0.5 x D | 1 x D | 460 | – | 620 | 414 | – | 558 | 414 | – | 558 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 | |

| 3 | 1.25 x D | 0.5 x D | 1 x D | 390 | – | 520 | 351 | – | 468 | 351 | – | 468 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | .0041 | |

| 4 | 1.25 x D | 0.4 x D | 0.75 x D | 300 | – | 490 | 270 | – | 441 | 270 | – | 441 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 | .0034 | |

| 5 | 1.25 x D | 0.4 x D | 1 x D | 200 | – | 330 | 170 | – | 280.5 | 160 | – | 264 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | .0033 | |

| 6 | 1.25 x D | 0.4 x D | 0.75 x D | 160 | – | 250 | 136 | – | 212.5 | 128 | – | 200 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| M | 1 | 1.25 x D | 0.4 x D | 1 x D | 300 | – | 380 | 240 | – | 304 | 210 | – | 266 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | .0041 |

| 2 | 1.25 x D | 0.4 x D | 1 x D | 200 | – | 260 | 160 | – | 208 | 140 | – | 182 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | .0033 | |

| 3 | 1.25 x D | 0.4 x D | 1 x D | 200 | – | 230 | 160 | – | 184 | 140 | – | 161 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

| K | 1 | 1.25 x D | 0.5 x D | 1 x D | 390 | – | 490 | 351 | – | 441 | 351 | – | 441 | IPT | .0023 | .0029 | .0034 | .0037 | .0042 | .0042 |

| 2 | 1.25 x D | 0.5 x D | 1 x D | 360 | – | 460 | 324 | – | 414 | 324 | – | 414 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | .0041 | |

| 3 | 1.25 x D | 0.5 x D | 1 x D | 360 | – | 430 | 324 | – | 387 | 324 | – | 387 | IPT | .0016 | .0020 | .0023 | .0026 | .0033 | .0033 | |

| S | 1 | 1 x D | 0.3 x D | 0.3 x D | 160 | – | 300 | 128 | – | 240 | 96 | – | 180 | IPT | .0019 | .0025 | .0029 | .0033 | .0041 | .0041 |

| 2 | 1 x D | 0.3 x D | 0.3 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | .0022 | |

| 3 | 1.25 x D | 0.3 x D | 0.3 x D | 80 | – | 130 | 64 | – | 104 | 48 | – | 78 | IPT | .0010 | .0013 | .0015 | .0018 | .0022 | .0022 | |

| 4 | 1.25 x D | 0.4 x D | 1 x D | 160 | – | 200 | 128 | – | 160 | 96 | – | 120 | IPT | .0014 | .0018 | .0021 | .0024 | .0030 | .0030 | |

| H | 1 | 1.25 x D | 0.4 x D | 0.75 x D | 260 | – | 460 | 208 | – | 368 | 156 | – | 276 | IPT | .0017 | .0022 | .0026 | .0029 | .0034 | .0034 |

| 2 | 1.25 x D | 0.2 x D | 0.5 x D | 230 | – | 390 | 184 | – | 312 | 138 | – | 234 | IPT | .0013 | .0016 | .0019 | .0021 | .0024 | .0024 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use