Produit similaire à:

KNS® • Arbor Mount • Metric

Slot milling cutter for multiple materials.

Numéro de matériel5614824

Ref. ISO CatalogueKNSM080N05X16K016Ref. ANSI CatalogueKNSM080N05X16K016

- P Acier

- M Acier inoxydable

- K Fonte

- N Non ferreux

- S Alliages hautes températures

100055043

Rainurage : fraisage de côté

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Aperçu

- Données d'application

- Téléchargements

- Pièces compatibles côté machine

- Pièces compatibles côté pièce

- Pièces de rechange

- Révision

- FAQ

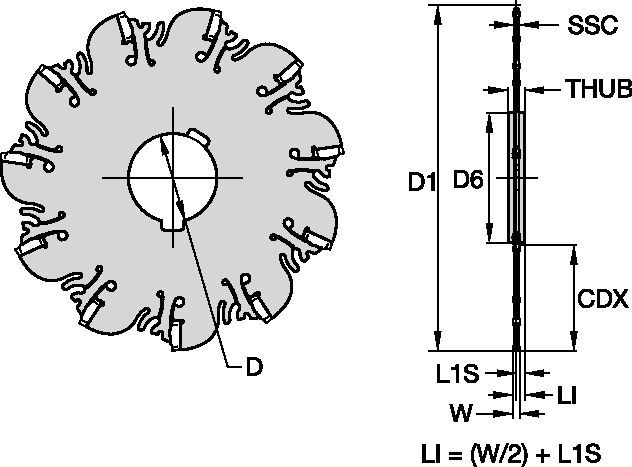

| Numéro de matériel | 5614824 |

| Ref. ISO Catalogue | KNSM080N05X16K016 |

| Ref. ANSI Catalogue | KNSM080N05X16K016 |

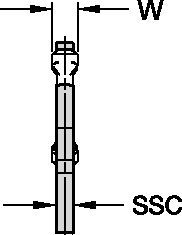

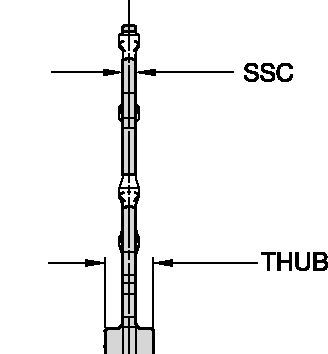

| Taille de la plaquette [SSC] | 16 |

| [BM] Largeur de coupe minimale | 1.9 mm |

| [BM] Largeur de coupe minimale | .075 in |

| [BMAX] Largeur de coupe maximale | 2.5 mm |

| [BMAX] Largeur de coupe maximale | .098 in |

| [D1] Diamètre effectif de coupe | 80 mm |

| [D1] Diamètre effectif de coupe | 3.15 in |

| [D] Adaptateur / Queue / Diamètre d’alésage | 16 mm |

| [D] Adaptateur / Queue / Diamètre d’alésage | .63 in |

| [D6] Diamètre du moyeu | 27 mm |

| [D6] Diamètre du moyeu | 1.063 in |

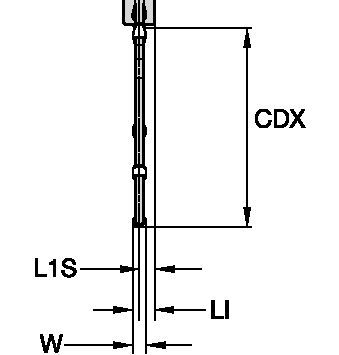

| [CDX] Profondeur de coupe radiale maximale | 25.7 mm |

| [CDX] Profondeur de coupe radiale maximale | 1.012 in |

| [L1S] Longueur de l’étalon secondaire | 3 mm |

| [L1S] Longueur de l’étalon secondaire | .118 in |

| [W1] Largeur de lame | 1.6 mm |

| [W1] Largeur de lame | .063 in |

| [THUB] Épaisseur du moyeu | 6 mm |

| [THUB] Épaisseur du moyeu | .236 in |

| Nombre de plaquettes | 5 |

| Plaquette étalon | XCP16_____ |

| Poids en kilogrammes | 0.06 |

| T/Min max | 1067 |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Fonte

- Non ferreux

- Alliages hautes températures

Uses and application

100055043

Rainurage : fraisage de côté

Features and benefits

- The Double-V Design of the insert and the insert pocket securely holds the insert in place, minimises radial runout, providing high slot width accuracy and high repeatability.

- A unique self-clamping mechanism ensures easy insert exchange.

- Integral hub for high accuracy and repeatability.

- Two-keyway hub design for gang slotting applications.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Guide de sélection des plaquettes

| KNS® Slotting Cutter • Insert Selection Guide | ||||||

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| – | (Hafif geometri) | (Sert geometri) | ||||

| – | Aşınma direnci |  | Tokluk | |||

| – | Geometri | Kalite | Geometri | Kalite | Geometri | Kalite |

| P1-P2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P3-P4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| P5-P6 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCPM40 |

| M1-M2 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| M3 | .S..GP | KCU25 | .S..GP | KCPM40 | .S..GP | KCPM40 |

| K1-K2 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| K3 | .S..GP | KCU25 | .S..GP | KCPK30 | .S..GP | KCPK30 |

| N1-N2 | – | – | .S..GP | KCU25 | – | – |

| N3 | – | – | .S..GP | KCU25 | – | – |

| S1-S2 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S3 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| S4 | .S..GP | KCU25 | .S..GP | KCU25 | .S..GP | KCU25 |

| H1 | – | – | – | – | – | – |

Feeds

Avances de départ recommandées [MM/Z]

| KNS® Slotting Cutter • Recommended Starting Feeds [mm/th] | ||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0,13 | 0,28 | 0,35 | 0,09 | 0,20 | 0,32 | 0,07 | 0,15 | 0,32 | 0,06 | 0,12 | 0,30 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

| KNS® Slotting Cutter • Recommended Starting Feeds [IPT] | ||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | |||||||||||

| 5% | 10% | 20% | 30–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| .S..GP | 0.005 | 0.011 | 0.027 | 0.004 | 0.008 | 0.020 | 0.003 | 0.006 | 0.015 | 0.002 | 0.005 | 0.012 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use "Light Machining" values as starting feed rate. | ||||||||||||

Speeds

Vitesses de départ recommandées [m/min]

| KNS® Slotting Cutter • Recommended Starting Speed [m/min] | ||||||||||

| Kalite | KCU25 | KCPK30 | KMF | |||||||

| Talaş kalınlığı hex mm | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | 260 | 230 | 215 | 455 | 395 | 370 | 295 | 260 | 245 |

| 2 | 220 | 190 | 160 | 280 | 255 | 230 | 250 | 215 | 180 | |

| 3 | 200 | 170 | 140 | 255 | 230 | 205 | 230 | 195 | 160 | |

| 4 | 180 | 150 | 120 | 225 | 185 | 160 | 205 | 170 | 135 | |

| 5 | 150 | 135 | 120 | 190 | 170 | 150 | 170 | 155 | 135 | |

| 6 | 130 | 100 | 80 | 160 | 135 | 110 | 150 | 115 | 90 | |

| M | 1 | 210 | 170 | 135 | 205 | 185 | 155 | 195 | 170 | 155 |

| 2 | 170 | 150 | 110 | 185 | 160 | 140 | 175 | 150 | 125 | |

| 3 | 130 | 120 | 85 | 145 | 130 | 115 | 130 | 115 | 90 | |

| K | 1 | 270 | 220 | 170 | 295 | 265 | 240 | – | – | – |

| 2 | 230 | 190 | 160 | 235 | 210 | 190 | – | – | – | |

| 3 | 210 | 160 | 140 | 195 | 175 | 160 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 |

| 2 | 30 | 25 | 20 | – | – | – | 40 | 35 | 30 | |

| 3 | 40 | 30 | 20 | – | – | – | 50 | 40 | 30 | |

| 4 | 55 | 40 | 25 | 50 | 45 | 35 | 55 | 50 | 35 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||

| KNS® Slotting Cutter • Recommended Starting Speed [SFM] | ||||||||||

| Kalite | KCPK30 | KCPK30 | KMF | |||||||

| Chip Thickness hex Inch | Min. | Maks. | Min. | Maks. | Min. | Maks. | ||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | 855 | 755 | 705 | 1495 | 1295 | 1215 | 970 | 855 | 805 |

| 2 | 720 | 625 | 525 | 920 | 835 | 755 | 820 | 705 | 590 | |

| 3 | 655 | 560 | 460 | 835 | 755 | 675 | 755 | 640 | 525 | |

| 4 | 590 | 490 | 395 | 740 | 605 | 525 | 675 | 560 | 445 | |

| 5 | 490 | 445 | 395 | 625 | 560 | 490 | 560 | 510 | 445 | |

| 6 | 425 | 330 | 260 | 525 | 445 | 360 | 490 | 375 | 295 | |

| M | 1 | 690 | 560 | 445 | 675 | 605 | 510 | 640 | 560 | 510 |

| 2 | 560 | 490 | 360 | 605 | 525 | 460 | 575 | 490 | 410 | |

| 3 | 425 | 395 | 280 | 475 | 425 | 375 | 425 | 375 | 295 | |

| K | 1 | 885 | 720 | 560 | 970 | 870 | 785 | – | – | – |

| 2 | 755 | 625 | 525 | 770 | 690 | 625 | – | – | – | |

| 3 | 690 | 525 | 460 | 640 | 575 | 525 | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 |

| 2 | 100 | 80 | 65 | – | – | – | 130 | 115 | 100 | |

| 3 | 130 | 100 | 65 | – | – | – | 165 | 130 | 100 | |

| 4 | 180 | 130 | 80 | 165 | 150 | 115 | 180 | 165 | 115 | |

| H | 1 | – | – | – | – | – | – | – | – | – |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | ||||||||||

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use