Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Turn up your volume for less with our limited-time offers! Shop Now

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Solid Carbide End Milling

- /

- High-Performance Solid Carbide End Mills

- /

- High-Performance Hard-Machining • Solid Carbide End Mills

- /

- KenCut™ HM • HPRDM • Radiused • 4 Flutes • Plain Shank • Inch

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

KenCut™ HM • HPRDM • Radiused • 4 Flutes • Plain Shank • Inch

Solid Carbide End Mill for Roughing of Steels and Hard Materials

Features and benefits

- Centre cutting for plunging and ramping operations.

- Solid carbide end mills for machining of hard materials greater than 60HRC.

- Also applicable in stainless steel, cast iron, and high-temperature alloys.

Uses and application

Ramping: Blank

Slotting: Square End

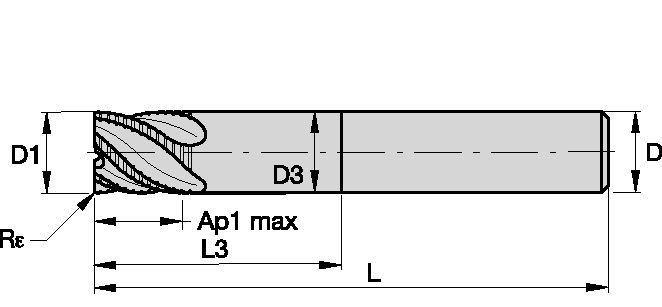

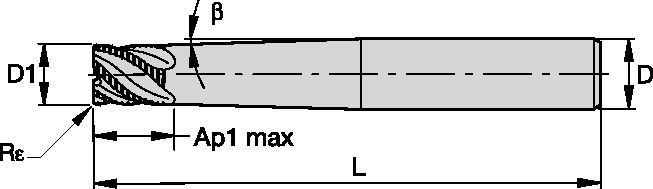

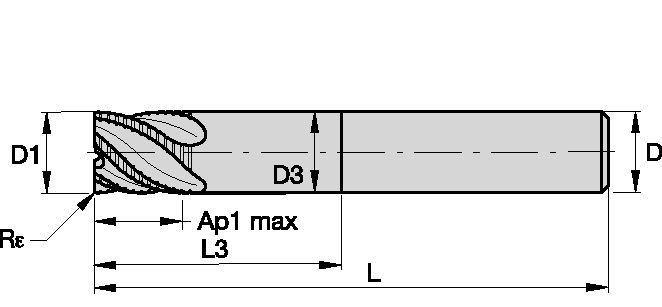

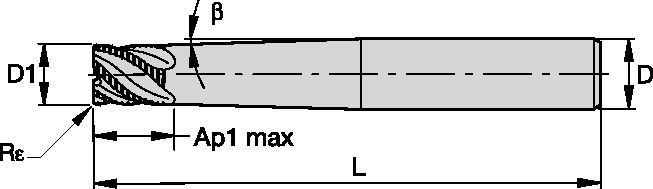

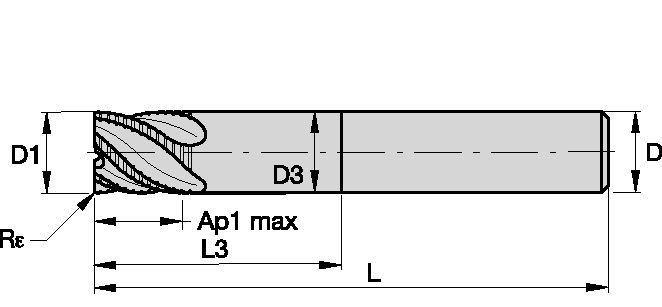

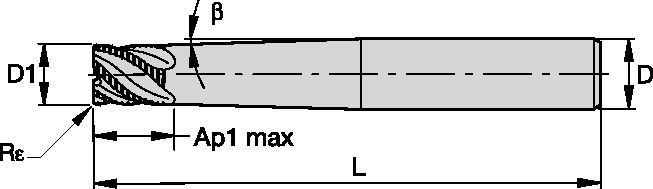

Tool Dimensions: Flute Configuration: X (variable)

Helix Angle: 45°

Corner Style: Corner Radius

Side Milling/Shoulder Milling: Roughing

| Parmak freze toleransları | |||

| D1 | Tolerans | D | Tolerans h6 + / - |

| 1/8" | -.0008/-.0031" | 1/8" | +0/-.00024" |

| 1/8–7/32" | -.0012/-.0041" | 1/8–7/32" | +0/-.00031" |

| 1/4–3/8" | -.0016/-.0051" | 1/4–3/8" | +0/-.00035" |

| 13/32–11/16" | -.002/-.0063" | 13/32–11/16" | +0/-.00043" |

| 23/32–1-3/16" | -.0026/-.0077" | 23/32–1-3/16" | +0/-.00051" |

|  |  | ||||||||||

| Dik kenar frezeleme (A) ve Kanal frezeleme (B) | KC633M | Feed per Tooth — fz information is for side milling (A). For slotting (B), reduce fz by 20%. | ||||||||||

| A | B | Kesme hızı | D1 | |||||||||

| 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | ||||||||

| Malzeme grubu | ap | ae | ap | min | max | inch | .188 | .250 | .313 | .375 | .500 | |

| P | 3 | 0.8 x D | 0.5 x D | 0.75 x D | 390 | 520 | IPT | .0011 | .0015 | .0020 | .0023 | .0029 |

| 4 | 0.8 x D | 0.4 x D | 0.5 x D | 300 | 490 | IPT | .0010 | .0014 | .0017 | .0020 | .0026 | |

| 5 | 0.8 x D | 0.5 x D | 0.75 x D | 200 | 330 | IPT | .0009 | .0012 | .0016 | .0018 | .0023 | |

| 6 | 0.8 x D | 0.4 x D | 0.5 x D | 160 | 250 | IPT | .0008 | .0010 | .0013 | .0015 | .0019 | |

| M | 1 | 0.8 x D | 0.5 x D | 0.75 x D | 300 | 380 | IPT | .0011 | .0015 | .0020 | .0023 | .0029 |

| 2 | 0.8 x D | 0.4 x D | 0.75 x D | 200 | 260 | IPT | .0009 | .0012 | .0016 | .0018 | .0023 | |

| 3 | 0.8 x D | 0.4 x D | 0.75 x D | 200 | 230 | IPT | .0008 | .0010 | .0013 | .0015 | .0019 | |

| K | 1 | 0.8 x D | 0.5 x D | 0.75 x D | 390 | 490 | IPT | .0013 | .0018 | .0023 | .0027 | .0034 |

| 2 | 0.8 x D | 0.5 x D | 0.75 x D | 360 | 460 | IPT | .0011 | .0015 | .0020 | .0023 | .0029 | |

| 3 | 0.8 x D | 0.4 x D | 0.75 x D | 360 | 430 | IPT | .0009 | .0012 | .0016 | .0018 | .0023 | |

| S | 1 | 0.8 x D | 0.4 x D | 0.75 x D | 160 | 300 | IPT | .0011 | .0015 | .0020 | .0023 | .0029 |

| 2 | 0.8 x D | 0.4 x D | 0.75 x D | 80 | 130 | IPT | .0006 | .0008 | .0010 | .0012 | .0015 | |

| 3 | 0.8 x D | 0.4 x D | 0.75 x D | 80 | 130 | IPT | .0006 | .0008 | .0010 | .0012 | .0015 | |

| 4 | 0.8 x D | 0.3 x D | 0.5 x D | 160 | 200 | IPT | .0008 | .0011 | .0014 | .0017 | .0021 | |

| H | 1 | 0.8 x D | 0.5 x D | 0.5 x D | 260 | 460 | IPT | .0010 | .0014 | .0017 | .0020 | .0026 |

| 2 | 0.8 x D | 0.2 x D | 0.3 x D | 230 | 390 | IPT | .0008 | .0010 | .0013 | .0015 | .0019 | |

| 3 | 0.8 x D | 0.15 x D | 0.2 x D | 200 | 300 | IPT | .0006 | .0008 | .0010 | .0012 | .0015 | |