Produit similaire à:

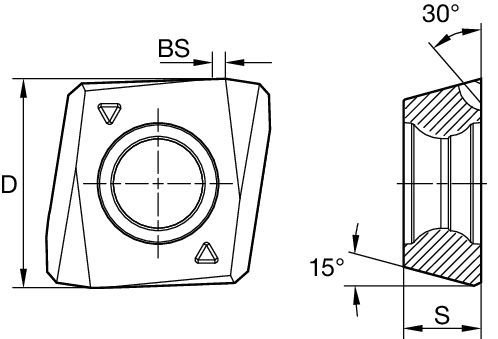

Fix-Perfect™ • Carbide Insert • MDHX-GD • Medium Machining

Milling Insert With Wiper Facet • Honed Cutting Edge

Numéro de matériel2404943

Ref. ISO CatalogueMDHX1004ZDERGDRef. ANSI CatalogueMDHX1004ZDERGD

- K Fonte

- N Non ferreux

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| Numéro de matériel | 2404943 |

| Ref. ISO Catalogue | MDHX1004ZDERGD |

| Ref. ANSI Catalogue | MDHX1004ZDERGD |

| Nuance | K110M |

Matériaux de pièce à usiner

- Fonte

- Non ferreux

Grades

K110M

Nuance de carbure non revêtu universelle destinée à l'usinage des non ferreux. Destinée surtout aux travaux généraux et légers. Le K110M s'utilise avec ou sans arrosage.

Features and benefits

- Milling insert for cast iron and compacted graphite iron (CGI) machining.

- High-precision periphery ground insert.

- Indexabe milling insert with four cutting edges.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Feeds

Avances de départ recommandées [mm]

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..GD4W | 0,23 | 0,84 | 1,41 | 0,17 | 0,60 | 1,01 | 0,13 | 0,45 | 0,75 | 0,11 | 0,39 | 0,66 | 0,10 | 0,36 | 0,60 | .F..GD4W |

| .E..GD4W | 0,26 | 0,93 | 1,67 | 0,19 | 0,67 | 1,19 | 0,14 | 0,50 | 0,88 | 0,12 | 0,44 | 0,77 | 0,11 | 0,40 | 0,70 | .E..GD4W |

| .E..GD | 0,26 | 1,03 | 1,90 | 0,19 | 0,74 | 1,35 | 0,14 | 0,55 | 1,00 | 0,12 | 0,48 | 0,87 | 0,11 | 0,44 | 0,80 | .E..GD |

| Travaux légers | Applications générales | Travaux lourds |

Recommended Starting Feeds [I.P.T.]

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .F..GD4W | .004 | .005 | .007 | .003 | .004 | .005 | .003 | .003 | .004 | .003 | .003 | .004 | .003 | .003 | .004 | .F..GD4W |

| .E..GD4W | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD4W |

| .E..GD | .005 | .006 | .008 | .004 | .005 | .006 | .003 | .004 | .005 | .003 | .004 | .005 | .003 | .004 | .005 | .E..GD |

| Travaux légers | Applications générales | Travaux lourds |

Speeds

Vitesses de départ recommandées [m/mn]

| Groupe Matières | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 155 | 145 | 135 | 325 | 295 | 260 | 275 | 235 | 195 |

| 2 | 135 | 130 | 120 | 255 | 225 | 215 | 220 | 180 | 160 | |

| 3 | 120 | 105 | 95 | 215 | 190 | 170 | 185 | 150 | 130 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Groupe Matières | K110M | KC520M | KTPK20 | |||||||

| P | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| K | 1 | 510 | 480 | 450 | 1060 | 960 | 850 | 910 | 770 | 640 |

| 2 | 450 | 420 | 390 | 830 | 740 | 700 | 720 | 590 | 520 | |

| 3 | 400 | 350 | 310 | 700 | 620 | 560 | 600 | 500 | 420 | |

| N | 1–2 | 1980 | 1860 | 1770 | – | – | – | – | – | – |

| 3 | 1620 | 1440 | 1260 | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – |

Guide de sélection des plaquettes

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| (géomètrie légère) | – | (géomètrie solide) | ||||

| résistance à l’usure |  | ténacité | ||||

| Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| K3 | .F..GD4W | KC520M | .E..GD4W | KC520M | .E..GD | KC520M |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data