Prodotto simile a :

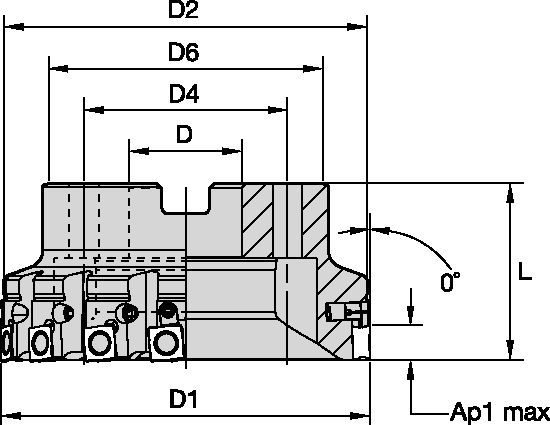

Fix-Perfect™ 0° Cast Iron Series • Shell Mill • Fixed Pockets • Inch

Tangential face milling cutter for cast iron machining.

Material Number1724407

ISO Catalog ID50A04RP90SP12CUFPANSI Catalog ID50A04RP90SP12CUFP

- P Acciaio

- M Acciai inossidabili

- K Ghisa

- S Leghe resistenti al calore

- .caption

Spianatura

Contornatura/fresatura a spallamento: Testa piana

Fresatura — Adduzione interna refrigerante

Fresatura — laterale e frontale

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Panoramica

- Dati dell'applicazione

- Downloads

- Parti compatibili lato macchina

- Parti compatibili lato pezzo

- Parti di ricambio

| Material Number | 1724407 |

| ISO Catalog ID | 50A04RP90SP12CUFP |

| ANSI Catalog ID | 50A04RP90SP12CUFP |

Materiale da lavorare

- Acciaio

- Acciai inossidabili

- Ghisa

- Leghe resistenti al calore

- .caption

Uses and application

Spianatura

Contornatura/fresatura a spallamento: Testa piana

Fresatura — Adduzione interna refrigerante

Fresatura — laterale e frontale

Features and benefits

- Milling cutter for roughing in cast iron and compacted graphite iron (CGI).

- High feed rates through tangentially mounted inserts.

- Pocket design protects non-engaged cutting edges.

- Insert stud clamping mechanism safely manages high RPM's.

Crea una soluzione per calcolare avanzamenti e velocità

Dopo aver creato una soluzione, basta scegliere l'icona Avanzamento e Velocità e il nostro sistema fornirà dei suggerimenti. Puoi personalizzare le informazioni aggiungendo la tua macchina e le specifiche o apportare delle modifiche utilizzando i cursori.

Feeds

Recommended Starting Feeds [IPT]

| Geometria dell'inserto | Avanzamento per dente programmato (fz) in base alla % della profondità di taglio radiale (ae) | Geometria dell'inserto | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GPB | .005 | .019 | .033 | .003 | .013 | .023 | .003 | .010 | .018 | .002 | .009 | .015 | .002 | .008 | .014 | .E..GPB |

| .T..GPB | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .T..GPB |

| .S..GPB | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .S..GPB |

| Lavorazione leggera | Uso generico | Lavorazione pesante |

| Lavorazione leggera | Uso generico | Lavorazione pesante |

| Geometria dell'inserto | Avanzamento per dente programmato (fz) in base alla % della profondità di taglio radiale (ae) | Geometria dell'inserto | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .E..GPB | .005 | .019 | .033 | .003 | .013 | .023 | .003 | .010 | .018 | .002 | .009 | .015 | .002 | .008 | .014 | .E..GPB |

| .T..GPB | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .T..GPB |

| .S..GPB | .009 | .023 | .037 | .007 | .017 | .027 | .005 | .013 | .020 | .004 | .011 | .017 | .004 | .010 | .016 | .S..GPB |

Speeds

Recommended Starting Speeds [SFM]

| Gruppo materiali | KB1340 | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 4500 | 3000 | 1600 | 880 | 800 | 710 | 1380 | 1255 | 1115 | 760 | 640 | 530 | 965 | 875 | 780 | 2640 | 2400 | 2130 |

| 2 | – | – | – | 690 | 620 | 580 | 1095 | 975 | 910 | 600 | 490 | 430 | 770 | 690 | 630 | 2090 | 1870 | 1740 | |

| 3 | – | – | – | 580 | 520 | 470 | 920 | 815 | 750 | 500 | 420 | 350 | 645 | 575 | 530 | 1760 | 1560 | 1430 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| Gruppo materiali | KB1340 | KC520M | KCK15 | KTPK20 | KCPK30 | KY3500 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 5 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 6 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| K | 1 | 4500 | 3000 | 1600 | 880 | 800 | 710 | 1380 | 1255 | 1115 | 760 | 640 | 530 | 965 | 875 | 780 | 2640 | 2400 | 2130 |

| 2 | – | – | – | 690 | 620 | 580 | 1095 | 975 | 910 | 600 | 490 | 430 | 770 | 690 | 630 | 2090 | 1870 | 1740 | |

| 3 | – | – | – | 580 | 520 | 470 | 920 | 815 | 750 | 500 | 420 | 350 | 645 | 575 | 530 | 1760 | 1560 | 1430 | |

| N | 1–2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Insert Selection

Insert Selection Guide

| Gruppo materiali | Lavorazione leggera | Uso generico | Lavorazione pesante | |||

| – | (Geometria leggera) | (Geometria robusta) | ||||

| – | resistenza all’usura |  | tenacità | |||

| – | Geometria | Qualità | Geometria | Qualità | Geometria | Qualità |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| K3 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

| Gruppo materiali | Lavorazione leggera | Uso generico | Lavorazione pesante | |||

| (Geometria leggera) | (Geometria robusta) | |||||

| resistenza all’usura |  | tenacità | ||||

| Geometria | Qualità | Geometria | Qualità | Geometria | Qualità | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| K3 | .E..GPB | KC520M | .E..GPB | KCK15 | .S..GPB | KCK15 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | – | – | – | – |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use