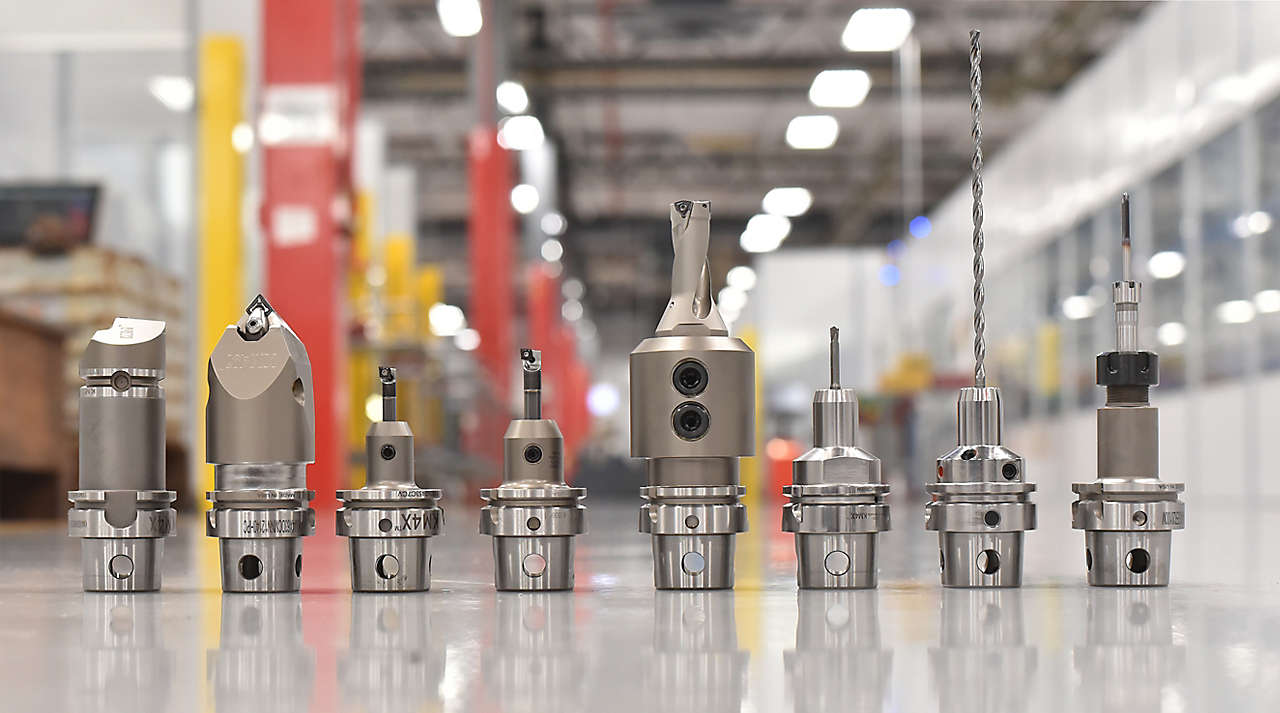

The performance of your machine operations are shaped by the attention given to your tooling solutions. Regarding tool holder maintenance, it’s vital to ensure the equipment between your cutting tools and the machine spindles works accurately and safely. In this blog, you’ll learn essential tips on maintenance practices for tool holders, along with some general recommendations to keep your machining operations running smoothly.

Tool Holder Maintenance

For many machine operators, some of this advice can be overlooked due to its obvious nature. However, taking the time to embrace or refresh yourself with these fundamentals can help prevent accidental damage to your workpiece, the lifespan of your tools, and most of all, safeguard yourself and your workforce.

Proper Storage of Tool Holders

Before storing tool holders, it's crucial to wipe off any coolant or debris from their surfaces. Coolant can lead to corrosion over time, negatively affecting the tool holder. After cleaning, lightly oil the tool holders to provide a protective barrier against moisture and rust.

Make sure your tool holders are placed in a toolbox, cart, drawer, or locker to avoid damage from falls or banging against each other. When storing tools in boxes, carts, or drawers, cover them properly to avoid sharp edges from causing injuries to anyone handling them. A well-organized storage system ensures that each tool holder remains in excellent condition when not in use.

Maintenance of Adaptors and Spindles

Adaptors: After use, it's essential to clean and oil the adaptors to prevent corrosion. Corrosion on adaptors can affect their fitting and lead to poor tool performance or even tool breakage.

Spindles: Regularly clean the spindle using spindle wipers to remove dirt, debris, and remnants of cutting fluids. A clean spindle ensures smooth tool changes and reduces the risk of damage to both the spindle and tool holders.

Always check the bending force of your tool holders before using them. Incorrect usage can cause fretting marks on the holders and may even lead to spindle damage. Follow the manufacturer's guidelines for proper usage and load capacity.

Avoid Dents and Scars

Inspect tool holders before each use to make sure your tool holders don’t have dents, scars, or signs of excessive wear. Damaged holders may not securely hold the cutting tool, leading to poor machining results and potential accidents.

General Tool Holder Maintenance

Bores: Keep the bore of the tool holders free from grease and dust. A clean bore ensures a precise fit and maximizes the tool holder's gripping efficiency.

Clamping Length and Adjustment: For efficient gripping, ensure that the minimum clamping length is met, especially for hydraulic chucks, shrinkers collet chucks, etc. Refer to the manufacturer's catalog for the right dimension or recommended clamping lengths.

Use Stop Screws for Length Adjustment: When adjusting the length of the tool holder, always use stop screws to prevent overextension and potential damage to the holder or spindle.

Torque Wrenches and Clamping: Use torque wrenches and tighten the tool holders with recommended torque values. Proper clamping ensures stable tool performance and reduces the risk of tool runout or vibrations.

- Coolant and Tool Protection: Regularly check the coolant for correct concentration and ensure it provides adequate corrosion protection. Corrosion can compromise the integrity of the tool.

Avoid Leaving Tools: Don’t leave tools out of their proper place for extended periods, especially if they are exposed to harsh environments. Such conditions can lead to rust and premature wear.

- Maintenance Accessories: Consider using spindle plugs and spindle wipers to protect the spindle from contamination and to maintain a clean environment for tool changes.

Ways to Save on Maintenance

Setting up a plan for preventing damage to equipment and implementing the proper procedures for your workforce goes hand in hand. You can potentially prevent injuries, ensuring everyone’s safety while at the same time increasing the lifecycle of your tools. Some additional best practices include:

Cleaning Stations: Set up dedicated stations with the appropriate cleaning materials for your tools. Having a designated area for cleaning and maintaining tool holders ensures consistency and efficiency in the maintenance process.

Tool holder Identification: Labeling each holder with relevant information, such as type, size, and usage history, can help you track maintenance schedules and identify potential issues quickly.

Temperature Settings: Store tool holders in an environment with controlled temperature and humidity levels. Extreme temperature fluctuations and high humidity can accelerate corrosion and degrade the performance of tool holders.

Grease and Lubricants: Choose the appropriate fluids for your tool holders based on the material and application they are being used for. Using the wrong type of lubricant can lead to performance issues.

Training and Education: Educating your team on the importance of maintenance and the potential consequences of neglecting it will foster a culture of care and responsibility.

By following these expert maintenance practices and recommendations, you can significantly extend the life of your tool holders, ensure precise machining, and guarantee the safety of your operators. Well-maintained tool holders not only enhance productivity but also contribute to the overall success of your machining operations.

Related Articles

- Buying Guide: Composite Materials Machining SolutionsWhen manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.When manufacturing composite materials, it is crucial to use top-notch equipment and techniques. Shop Kennametal's specialized tooling for composites now.

- KOR™5 DA: How to Make Aluminum (Chips) FlyKennametal’s KOR5 DA solid end mill has high feed rates & Material Removal Rates [MRR]. Meet Danny Davis and Steve George, the engineers who worked on the design and learn how to cut aluminum like a king!Kennametal’s KOR5 DA solid end mill has high feed rates & Material Removal Rates [MRR]. Meet Danny Davis and Steve George, the engineers who worked on the design and learn how to cut aluminum like a king!

- Tips to Reduce Waste in MachiningWould you like to be more cost-effective when machining? Find out some helpful tips on how to reduce waste and save on production costs.Would you like to be more cost-effective when machining? Find out some helpful tips on how to reduce waste and save on production costs.

- Essential Tips on Tool Holder Maintenance Mastering tool holder maintenance with these expert tips ensures precise machining, extends tool life, and enhances productivity. Learn more.Mastering tool holder maintenance with these expert tips ensures precise machining, extends tool life, and enhances productivity. Learn more.