欢迎

请确认您的首选项

更新首选项

产品建议

Product Family suggestions

编辑解决方案

添加解决方案

解决方案名称:{{SolutionName}}Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

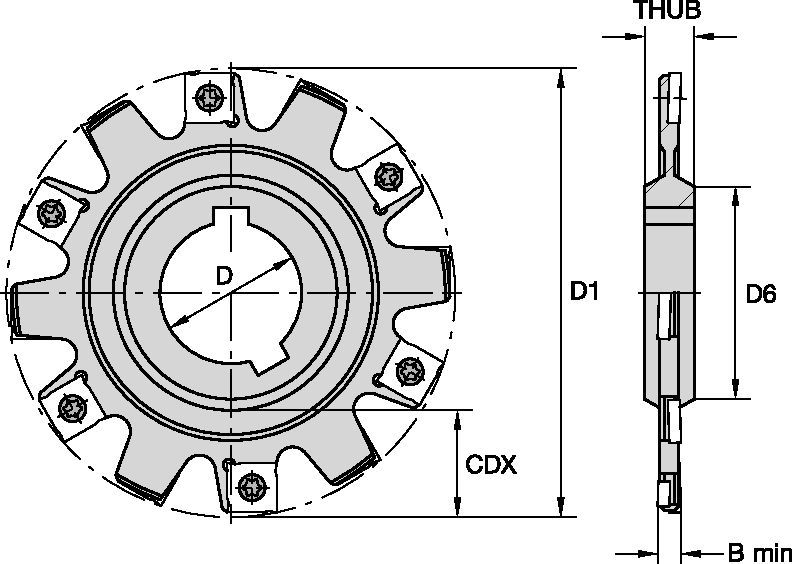

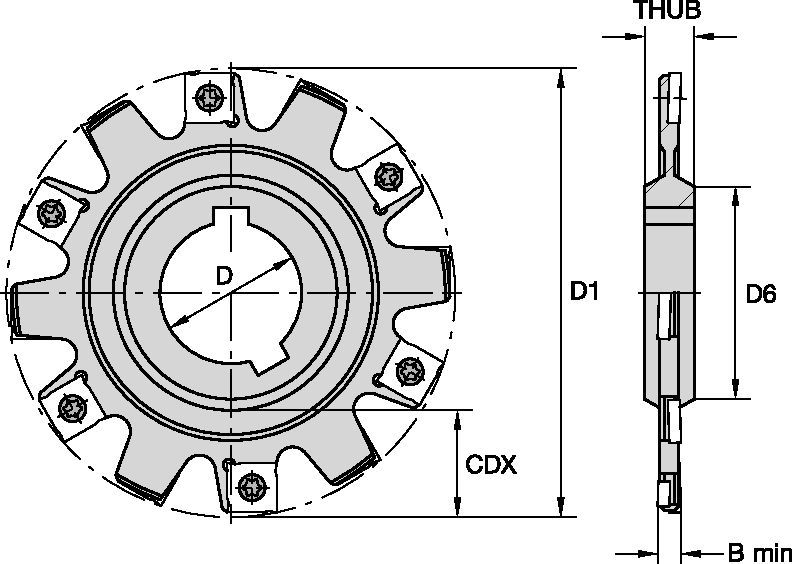

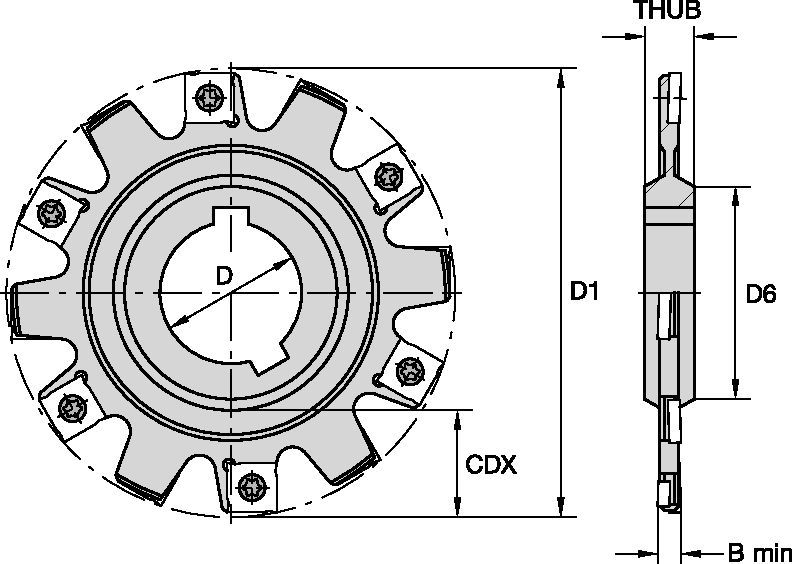

90° SN 槽铣刀 • 芯轴接口 • 全侧切 • 公制

窄槽铣刀 • A 型, 芯轴接口

Features and benefits

- 4–14mm 铣槽宽度范围。

- 每个刀片有四个转位。

- 三种刀片槽型可选。

- 错列式接口有两个键槽。

- 仅需一个配件。

Uses and application

槽铣: AE/AP尺寸侧铣

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .T..GP | KCPM40 | .T..GP | KCPM40 | ..T | KCPM40 |

| P3–P4 | .T..GP | KCPK30 | .T..GP | KCPM40 | ..T | KCPM40 |

| P5–P6 | .T..GP | KCPK30 | ..T | KCPK30 | ..T | KCPM40 |

| M1–M2 | .T..GP | KC725M | .T..GP | KC725M | ..T | KC725M |

| M3 | .T..GP | KCPM40 | .T..GP | KCPM40 | ..T | KCPM40 |

| K1–K2 | ..T | KC520M | ..T | KC520M | ..T | KC520M |

| K3 | .T..GP | KCPK30 | .T..GP | KCPK30 | ..T | KCPK30 |

| N1–N2 | .F..GE | KC510M | .F..GE | KC510M | .T..GP | K110M |

| N3 | .T..GP | K110M | .T..GP | K110M | .T..GP | K110M |

| S1–S2 | .T..GP | KC725M | .T..GP | KC725M | ..T | KC725M |

| S3 | .T..GP | KCPM40 | .T..GP | KCPM40 | ..T | KCPM40 |

| S4 | .T..GP | KC725M | ..T | KC725M | ..T | KC725M |

| H1 | .F..GE | KC510M | – | – | – | – |

推荐初始进给率 [mm]

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..GE | 0,13 | 0,42 | 0,70 | 0,09 | 0,30 | 0,50 | 0,07 | 0,23 | 0,38 | 0,06 | 0,20 | 0,33 | 0,06 | 0,18 | 0,30 | .F..GE |

| .T..GP | 0,23 | 0,47 | 0,70 | 0,17 | 0,34 | 0,50 | 0,13 | 0,25 | 0,38 | 0,11 | 0,22 | 0,33 | 0,10 | 0,20 | 0,30 | .T..GP |

| ..T | 0,23 | 0,56 | 0,82 | 0,17 | 0,40 | 0,59 | 0,13 | 0,30 | 0,44 | 0,11 | 0,26 | 0,38 | 0,10 | 0,24 | 0,35 | ..T |

推荐初始速度 [m/min]

| Material Group | KC110M | KC510M | KC520M | KC725M | KC735M | KCPK30 | |||||||||||||

| P | 1 | – | – | – | – | – | – | – | – | – | 260 | 230 | 215 | – | – | – | 455 | 395 | 370 |

| 2 | – | – | – | – | – | – | – | – | – | 220 | 190 | 160 | – | – | – | 280 | 255 | 230 | |

| 3 | – | – | – | – | – | – | – | – | – | 200 | 170 | 140 | – | – | – | 255 | 230 | 205 | |

| 4 | – | – | – | – | – | – | – | – | – | 180 | 150 | 120 | – | – | – | 190 | 175 | 160 | |

| 5 | – | – | – | – | – | – | – | – | – | 150 | 135 | 120 | – | – | – | 260 | 230 | 210 | |

| 6 | – | – | – | – | – | – | – | – | – | 130 | 100 | 80 | – | – | – | 160 | 135 | – | |

| M | 1 | – | – | – | – | – | – | – | – | – | 170 | 150 | 135 | 105 | 90 | 80 | 205 | 185 | 155 |

| 2 | – | – | – | – | – | – | – | – | – | 155 | 130 | 110 | 95 | 85 | 75 | 185 | 160 | 140 | |

| 3 | – | – | – | – | – | – | – | – | – | 115 | 100 | 80 | 70 | 60 | – | 145 | 130 | 115 | |

| K | 1 | 130 | 120 | 115 | 295 | 265 | 240 | 270 | 245 | 215 | – | – | – | – | – | – | 295 | 265 | 240 |

| 2 | 115 | 105 | 100 | 230 | 205 | 190 | 210 | 190 | 175 | – | – | – | – | – | – | 235 | 210 | 190 | |

| 3 | 100 | 90 | 80 | 195 | 175 | 160 | 175 | 160 | 145 | – | – | – | – | – | – | 195 | 175 | 160 | |

| N | 1–2 | 505 | 475 | 450 | 640 | 570 | 525 | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 410 | 365 | 320 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 35 | 30 | 25 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | 35 | 30 | 25 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | 45 | 35 | 25 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | – | – | – | 60 | 45 | 30 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |