欢迎

请确认您的首选项

更新首选项

产品建议

Product Family suggestions

编辑解决方案

添加解决方案

解决方案名称:{{SolutionName}}Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

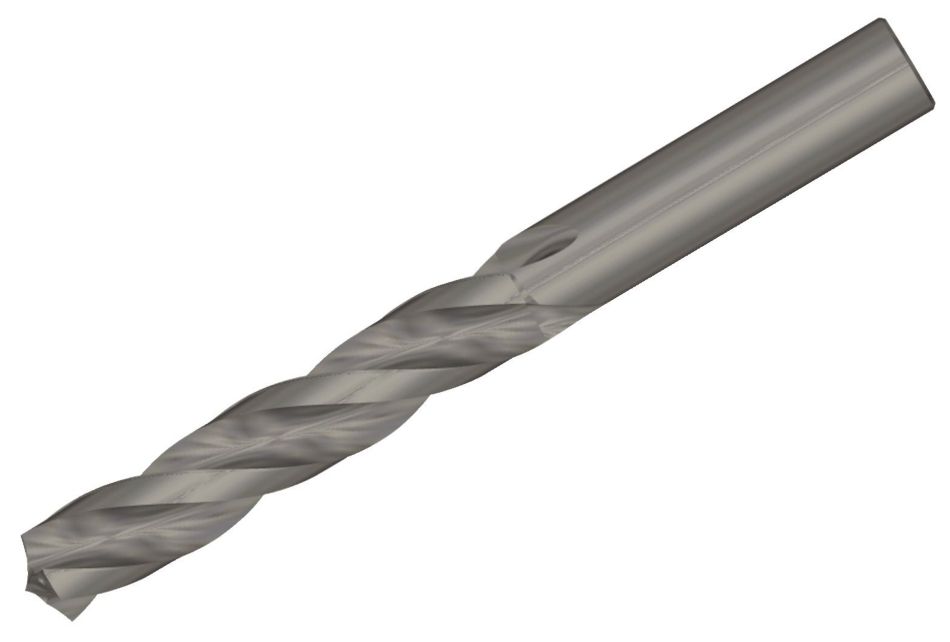

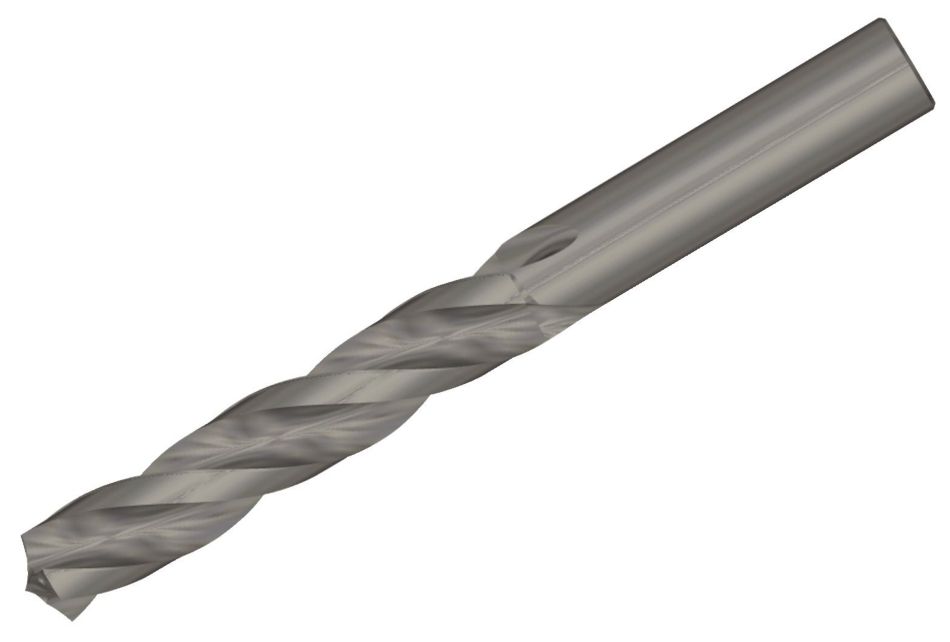

K125 (~5 x D) • K715 • A-刀柄 • TF 钻头

TF 钻头 • 钛材料 • 内冷 • 应用数据

Features and benefits

- TF drills with through coolant for titanium materials.

- Material-specific SC drill with three cutting edges for higher feed rates than with two-edged drills.

- Three spacious flutes for rapid chip evacuation.

- Three-margin lands deliver better hole quality and straightness than two-flute drills.

- Through-coolant design for improved chip evacuation enables deeper holes and more effective cooling of the cutting edges and longer tool life.

- K715 fine-grained carbide grade is the optimum combination of toughness and wear resistance for titanium drilling applications.

Uses and application

钻孔

钻孔: 斜退刀

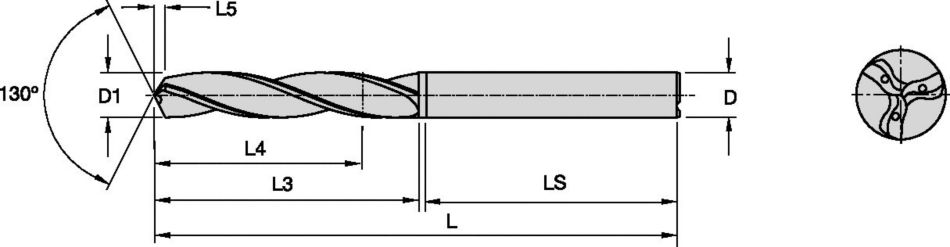

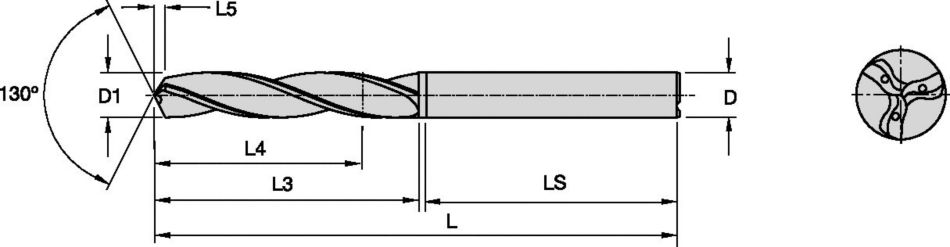

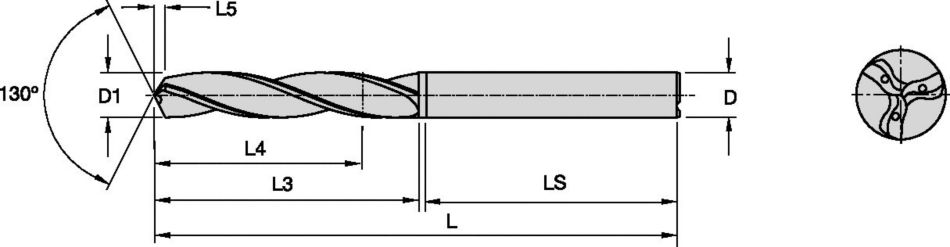

刀具尺寸: 3个排屑槽/3个刃带/冷却

钻孔 — 贯通式冷却

刀柄— 圆柱 平面度 ≤h6

螺旋角: 30°

Drilling: Cross-Hole Drilling

| Tolerans • İnç | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

| Tolerans • Metrik | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

TF 钻 • B/K125 系列 • K715 材质™ • 内冷 • 钻头直径范围为 .1181–.7874″ • 英制

| Malzeme grubu |  |  | |||||||||||

| Malzeme grubu | Kesme hızı | İnç | |||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| S | 4 | 70 | 100 | 160 | IPR | – | – | .001–.003 | .001–.003 | .001–.003 | .003–.006 | .003–.006 | – |

| Malzeme grubu |  |  | |||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| S | 4 | 20 | 30 | 50 | mm/dev | – | – | 0,03–0,08 | 0,03–0,08 | 0,03–0,08 | 0,08–0,15 | 0,08–0,15 | – |

|  | ||||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Malzeme grubu | Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| S | 4 | 20 | 30 | 50 | mm/dev | – | – | 0,03–0,08 | 0,03–0,08 | 0,03–0,08 | 0,08–0,15 | 0,08–0,15 | – |

| Malzeme grubu |  |  | |||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | |||

| K | 1 | 60 | 85 | 110 | mm/dev | 0,11–0,20 | 0,12–0,20 | 0,16–0,28 | 0,20–0,35 | 0,22–0,42 | 0,24–0,50 | 0,28–0,61 | 0,30–0,68 |

| 2 | 70 | 70 | 90 | mm/dev | 0,11–0,20 | 0,12–0,20 | 0,16–0,28 | 0,20–0,35 | 0,22–0,42 | 0,24–0,50 | 0,28–0,61 | 0,30–0,68 | |

| 3 | 50 | 50 | 70 | mm/dev | 0,09–0,18 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | 0,02–0,40 | 0,22–0,48 | 0,26–0,59 | 0,28–0,66 | |

| N | 1 | 100 | 210 | 410 | mm/dev | 0,09–0,15 | 0,10–0,20 | 0,18–0,33 | 0,20–0,38 | 0,25–0,43 | 0,03–0,51 | 0,43–0,58 | 0,64–0,79 |

| 2 | 100 | 250 | 250 | mm/dev | 0,10–0,19 | 0,12–0,21 | 0,18–0,33 | 0,25–0,42 | 0,30–0,50 | 0,35–0,58 | 0,44–0,74 | 0,52–0,88 | |

| 3 | 100 | 180 | 400 | mm/dev | 0,09–0,16 | 0,10–0,20 | 0,12–0,26 | 0,16–0,36 | 0,20–0,40 | 0,24–0,45 | 0,30–0,50 | 0,34–0,60 | |

| 4 | 60 | 170 | 250 | mm/dev | 0,08–0,15 | 0,13–0,18 | 0,18–0,33 | 0,20–0,36 | 0,23–0,38 | 0,33–0,46 | 0,38–0,48 | 0,58–0,76 | |

| S | 4 | 20 | 20 | 50 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,07–0,09 | 0,09–0,12 | 0,11–0,15 | 0,13–0,18 | 0,17–0,24 | 0,22–0,30 |

| Malzeme grubu |  |  | |||||||||||

| Malzeme grubu | Kesme hızı | İnç | |||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 5/8 .625 | 3/4 .750 | |||

| K | 1 | 200 | 280 | 360 | IPR | .004–.008 | .005–.008 | .006–.011 | .008–.014 | .009–.017 | .009–.020 | .011–.024 | .012–.027 |

| 2 | 230 | 230 | 300 | IPR | .004–.008 | .005–.008 | .006–.011 | .008–.014 | .009–.017 | .009–.020 | .011–.024 | .012–.027 | |

| 3 | 160 | 160 | 230 | IPR | .004–.007 | .004–.007 | .006–.010 | .007–.013 | .001–.016 | .009–.019 | .010–.023 | .011–.026 | |

| N | 1 | 330 | 690 | 1340 | IPR | .004–.006 | .004–.008 | .007–.013 | .008–.015 | .010–.017 | .001–.020 | .017–.023 | .025–.031 |

| 2 | 330 | 820 | 820 | IPR | .004–.008 | .005–.008 | .007–.013 | .010–.017 | .012–.020 | .014–.023 | .017–.029 | .021–.035 | |

| 3 | 330 | 590 | 1310 | IPR | .004–.006 | .004–.008 | .005–.010 | .006–.014 | .008–.016 | .009–.018 | .012–.020 | .013–.024 | |

| 4 | 200 | 560 | 820 | IPR | .003–.006 | .005–.007 | .007–.013 | .008–.014 | .009–.015 | .013–.018 | .015–.019 | .023–.030 | |

| S | 4 | 70 | 70 | 160 | IPR | .001–.002 | .002–.003 | .003–.004 | .004–.005 | .004–.006 | .005–.007 | .007–.009 | .009–.012 |

|  | ||||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Malzeme grubu | Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 16,0 | 20,0 | ||

| K | 1 | 60 | 85 | 110 | mm/dev | 0,11–0,20 | 0,12–0,20 | 0,16–0,28 | 0,20–0,35 | 0,22–0,42 | 0,24–0,50 | 0,28–0,61 | 0,30–0,68 |

| 2 | 70 | 72 | 90 | mm/dev | 0,11–0,20 | 0,12–0,20 | 0,16–0,28 | 0,20–0,35 | 0,22–0,42 | 0,24–0,50 | 0,28–0,61 | 0,30–0,68 | |

| 3 | 50 | 51 | 70 | mm/dev | 0,09–0,18 | 0,10–0,18 | 0,14–0,26 | 0,18–0,33 | ,020–0,40 | 0,22–0,48 | 0,26–0,59 | 0,28–0,66 | |

| N | 1 | 100 | 210 | 410 | mm/dev | 0,09–0,15 | 0,10–0,20 | 0,18–0,33 | 0,20–0,38 | 0,25–0,43 | ,033–0,51 | 0,43–0,58 | 0,64–0,79 |

| 2 | 100 | 248 | 250 | mm/dev | 0,10–0,19 | 0,12–0,21 | 0,18–0,33 | 0,25–0,42 | 0,30–0,50 | 0,35–0,58 | 0,44–0,74 | 0,52–0,88 | |

| 4 | 60 | 173 | 250 | mm/dev | 0,08–0,15 | 0,13–0,18 | 0,18–0,33 | 0,20–0,36 | 0,23–0,38 | 0,33–0,46 | 0,38–0,48 | 0,58–0,76 | |

| S | 4 | 30 | 20 | 51 | mm/dev | 0,03–0,05 | 0,04–0,07 | 0,07–0,09 | 0,09–0,12 | 0,11–0,15 | 0,13–0,18 | 0,17–0,24 | 0,22–0,30 |