5505VX Weldon End Mills • Stellram • Inch

Ball Nose Milling Cutter

物料号5673110

公制样本编号C5505VX12WA1.50R6.00英制样本编号C5505VX12WA1.50R6.00

- P 钢

- M 不锈钢

- S 高温合金

- .caption

3D仿形加工

刀柄— 圆柱 Weldon

铣削 — 贯通式冷却

Inclined Square End Mill

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

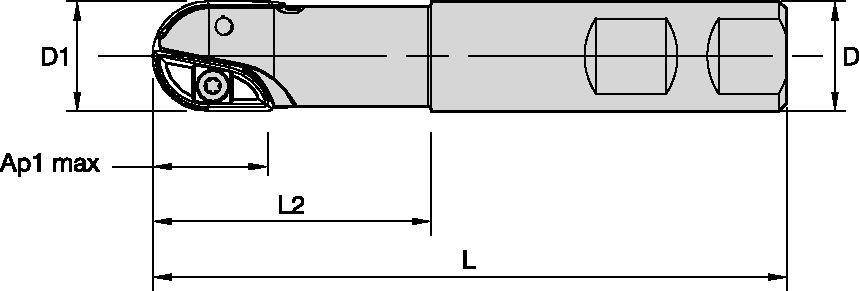

| 物料号 | 5673110 |

| 公制样本编号 | C5505VX12WA1.50R6.00 |

| 英制样本编号 | C5505VX12WA1.50R6.00 |

| [D1] 有效的切削直径 | 38.1 mm |

| [D1] 有效的切削直径 | 1.5 in |

| [D]适配接头/刀柄/镗孔直径 | 38.1 mm |

| [D]适配接头/刀柄/镗孔直径 | 1.5 in |

| [L] 总长 | 220.58 mm |

| [L] 总长 | 8.6843 in |

| [L2] 刀头长度 | 152.3 mm |

| [L2] 刀头长度 | 5.9961 in |

| [AP1MAX] 第一个最大切深 | 38.1 mm |

| [AP1MAX] 第一个最大切深 | 1.5 in |

| 刀片数量 | 2 |

工件材料

- 钢

- 不锈钢

- 高温合金

- .caption

Uses and application

3D仿形加工

刀柄— 圆柱 Weldon

铣削 — 贯通式冷却

Inclined Square End Mill

Features and benefits

- Rough to semi-finish profiling and contour milling.

- Helical insert design for increased speeds and feeds.

- One insert geometry covers most materials for optimized inventory.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

Feeds

At .315 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .009 | .016 | .003 | .007 | .011 | .002 | .005 | .009 | .002 | .004 | .007 | .002 | .004 | .007 | R-F |

At .157 Axial Depth of Cut (ap)

| 轻切削 | 中等切削 | 重切削 |

At .079 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .008 | .014 | .003 | .006 | .010 | .002 | .004 | .007 | .002 | .004 | .006 | .002 | .004 | .006 | R-F |

At .039 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .008 | .017 | .028 | .006 | .012 | .020 | .004 | .009 | .015 | .004 | .008 | .013 | .003 | .007 | .012 | R-F |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .006 | .012 | .021 | .004 | .009 | .015 | .003 | .007 | .011 | .003 | .006 | .010 | .002 | .005 | .009 | R-F |

At .394 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .010 | .016 | .003 | .007 | .011 | .002 | .006 | .008 | .002 | .005 | .007 | .002 | .004 | .007 | R-F |

At .197 Axial Depth of Cut (ap)

| 轻切削 | 中等切削 | 重切削 |

At .098 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .012 | .018 | .003 | .009 | .013 | .002 | .006 | .010 | .002 | .006 | .008 | .002 | .005 | .008 | R-F |

At .049 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .008 | .021 | .032 | .006 | .015 | .023 | .004 | .012 | .017 | .004 | .010 | .015 | .003 | .009 | .014 | R-F |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .006 | .016 | .024 | .004 | .011 | .017 | .003 | .008 | .013 | .003 | .007 | .011 | .002 | .007 | .010 | R-F |

At .492 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .011 | .019 | .003 | .008 | .013 | .002 | .006 | .010 | .002 | .005 | .009 | .002 | .005 | .008 | R-F |

At .250 Axial Depth of Cut (ap)

| 轻切削 | 中等切削 | 重切削 |

At .125 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .013 | .021 | .003 | .010 | .015 | .002 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .009 | R-F |

At .063 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .008 | .024 | .038 | .005 | .017 | .028 | .004 | .013 | .021 | .004 | .011 | .018 | .003 | .010 | .016 | R-F |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .006 | .017 | .028 | .004 | .012 | .020 | .003 | .009 | .015 | .003 | .008 | .013 | .002 | .007 | .012 | R-F |

At .630 Axial Depth of Cut (ap)

| 轻切削 | 中等切削 | 重切削 |

At .315 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .011 | .019 | .003 | .008 | .013 | .002 | .006 | .010 | .002 | .005 | .009 | .002 | .005 | .008 | R-F |

At .157 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .013 | .021 | .003 | .010 | .015 | .002 | .007 | .012 | .002 | .006 | .010 | .002 | .006 | .009 | R-F |

At .079 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .008 | .024 | .039 | .006 | .017 | .028 | .004 | .013 | .021 | .004 | .011 | .018 | .003 | .010 | .017 | R-F |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .006 | .017 | .028 | .004 | .013 | .020 | .003 | .009 | .015 | .003 | .008 | .013 | .002 | .007 | .012 | R-F |

At .787 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .013 | .022 | .003 | .009 | .016 | .002 | .007 | .012 | .002 | .006 | .010 | .002 | .005 | .010 | R-F |

At .394 Axial Depth of Cut (ap)

| 轻切削 | 中等切削 | 重切削 |

At .197 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .008 | .026 | .047 | .006 | .019 | .033 | .004 | .014 | .025 | .004 | .012 | .022 | .003 | .011 | .020 | R-F |

At .098 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .015 | .026 | .003 | .010 | .019 | .002 | .008 | .014 | .002 | .007 | .012 | .002 | .006 | .011 | R-F |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .006 | .019 | .034 | .004 | .014 | .024 | .003 | .010 | .018 | .003 | .009 | .016 | .002 | .008 | .015 | R-F |

At .984 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .015 | .025 | .003 | .011 | .018 | .002 | .008 | .014 | .002 | .007 | .012 | .002 | .006 | .011 | R-F |

At .500 Axial Depth of Cut (ap)

| 轻切削 | 中等切削 | 重切削 |

At .250 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .004 | .017 | .029 | .003 | .012 | .021 | .002 | .009 | .016 | .002 | .008 | .014 | .002 | .007 | .012 | R-F |

At .125 Axial Depth of Cut (ap)

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .008 | .031 | .052 | .005 | .022 | .038 | .004 | .016 | .028 | .004 | .014 | .024 | .003 | .013 | .022 | R-F |

| 刀片槽型 | 不同切宽(ae)百分比情况下,所建议的每齿进给量设定值(fz) | 刀片槽型 | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| R-F | .006 | .022 | .038 | .004 | .016 | .027 | .003 | .012 | .020 | .003 | .010 | .018 | .002 | .010 | .016 | R-F |

High Performance Combination Tools

刀片选择指南

| 材料 分组 | 轻切削 | 中等切削 | 重切削 | |||

| – | (锋利的槽型) | – | (强壮的槽型) | |||

| – | 耐磨性 |  | 韧性 | |||

| – | 槽型 | 材质 | 槽型 | 材质 | 槽型 | 材质 |

| P1–P2 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| P3–P4 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| P5–P6 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| M1–M2 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| M3 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| K1–K2 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| K3 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| S3 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| S4 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

| H1 | R-F | SP6519 | R-F | SP6519 | R-F | SP6519 |

I have read and accepted the Terms & Conditions of use