B271Z_HP (15 x D) • KN25 • Z 型刀杆 • HP 深孔钻

Beyond™ SC 深孔钻 • 多种材料 • 内冷

物料号3867767

公制样本编号B271Z09000HPS英制样本编号B271Z09000HPS

- N 非铁材质

Drilling: Stacked Plates

钻孔

钻孔: 斜退刀

刀具尺寸: 2个排屑槽/4个刃带/冷却

DIN号码6535

钻孔 — 贯通式冷却

贯通式冷却: MQL(微量润滑): 钻孔

刀柄— 圆柱 平面度 ≤h6

螺旋角: 30°

Drilling: Cross-Hole Drilling

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 3867767 |

| 公制样本编号 | B271Z09000HPS |

| 英制样本编号 | B271Z09000HPS |

| 材质 | KN25 |

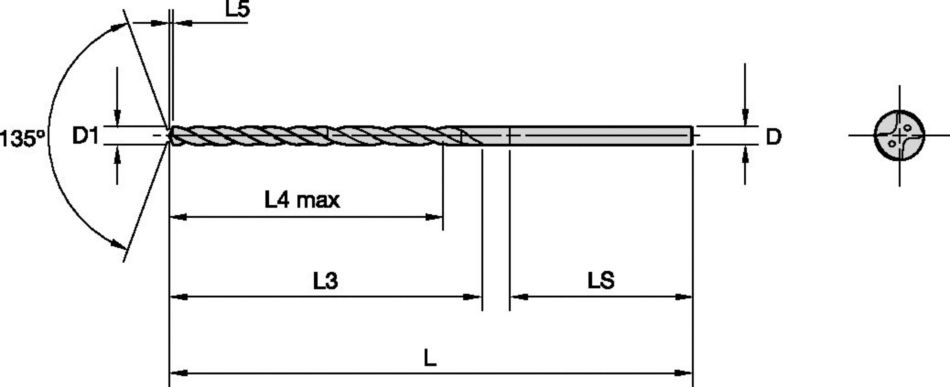

| [D1] 钻头直径 M | 9 mm |

| [D1] 钻头直径 M | .3543 in |

| [L] 总长 | 200 mm |

| [L] 总长 | 7.874 in |

| [L3] 排屑槽长度 | 155 mm |

| [L3] 排屑槽长度 | 6.102 in |

| [L4] 最大钻孔深度 | 135 mm |

| [L4] 最大钻孔深度 | 5.315 in |

| [L5] 钻尖长度 | 1.66 mm |

| [L5] 钻尖长度 | .0654 in |

| [LS] 刀柄长度 | 42 mm |

| [LS] 刀柄长度 | 1.653 in |

| [D]适配接头/刀柄/镗孔直径 | 9 mm |

| [D]适配接头/刀柄/镗孔直径 | .3543 in |

工件材料

- 非铁材质

Uses and application

Drilling: Stacked Plates

钻孔

钻孔: 斜退刀

刀具尺寸: 2个排屑槽/4个刃带/冷却

DIN号码6535

钻孔 — 贯通式冷却

贯通式冷却: MQL(微量润滑): 钻孔

刀柄— 圆柱 平面度 ≤h6

螺旋角: 30°

Drilling: Cross-Hole Drilling

Features and benefits

- HP 整体硬质合金深孔钻,内冷性能,用于钢、铸铁、以及非铁金属材料加工。

- 根据应用需求设计的整体硬质合金钻,钻孔深度可达 15 x D, 与常规 HSS 和枪钻产品相比,钻孔速度可以提高四倍。

- 市场上直径范围最为广泛的产品系列,直径范围为 2,383–16mm (.0938–.6299″)。

- 提供 KMH 非标钻尖槽型,特别适合曲轴加工应用。

- KCPK20™ 材质 (B27_HPG) 采用 AlCrN-TiAlN 涂层,具备卓越的耐磨性能。新型超细晶体硬质合金确保在钢铁材料高进给加工中有更好的可靠性。

- KN25™ Beyond 非涂层材质 (B27_HPS) 具有极佳的抛光度,在铝和高温合金材料加工中可确保出色的排屑性能,即使在低压冷却或微量润滑情况下也是如此。

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

公差

| TOLERANCE • Inch | ||||

| Drills *HPG, *SGL, *HPR | Drills *HPS | |||

| nominal size range | D1 tolerance h7 | D tolerance h6 | D1 tolerance h8 | D tolerance h6 |

| .0394 to .1181 | .0000/-.0004 | .0000/-.0002 | .0000/-.0006 | .0000/-.0002 |

| .1181 to .2362 | .0000/-.0005 | .0000/-.0003 | .0000/-.0007 | .0000/-.0003 |

| .2362 to .3937 | .0000/-.0006 | .0000/-.0004 | .0000/-.0009 | .0000/-.0004 |

| .3937 to .7087 | .0000/-.0007 | .0000/-.0004 | .0000/-.0011 | .0000/-.0004 |

| TOLERANCE • Metric | ||||

| Drills *HPG, *SGL, *HPR | Drills *HPS | |||

| nominal size range | D1 tolerance h7 | D tolerance h6 | D1 tolerance h8 | D tolerance h6 |

| .0394 to .1181 | 0,000/-0,010 | 0,000/-0,006 | 0,000/-0,014 | 0,000/-0,006 |

| .1181 to .2362 | 0,000/-0,012 | 0,000/-0,008 | 0,000/-0,018 | 0,000/-0,008 |

| .2362 to .3937 | 0,000/-0,015 | 0,000/-0,009 | 0,000/-0,022 | 0,000/-0,009 |

| .3937 to .7087 | 0,000/-0,018 | 0,000/-0,011 | 0,000/-0,027 | 0,000/-0,011 |

应用数据

| Malzeme grubu |  |  | |||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | |||

| N | 1 | 120 | 200 | 300 | mm/dev | 0,12 | 0,13 | 0,15 | 0,19 | 0,26 | 0,31 | 0,35 | 0,41 |

| 2 | 120 | 170 | 300 | mm/dev | 0,13 | 0,14 | 0,16 | 0,20 | 0,28 | 0,33 | 0,38 | 0,44 | |

| 3 | 100 | 150 | 300 | mm/dev | 0,13 | 0,14 | 0,16 | 0,20 | 0,28 | 0,33 | 0,38 | 0,44 | |

| 4 | 80 | 200 | 300 | mm/dev | 0,03 | 0,03 | 0,03 | 0,04 | 0,05 | 0,05 | 0,05 | 0,06 | |

| Malzeme grubu |  |  | |||||||||||

| Malzeme grubu | Kesme hızı | İnç | |||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 0.551 | 5/8 .625 | |||

| N | 1 | 390 | 660 | 980 | IPR | .005–.007 | .005–.007 | .006–.009 | .008–.011 | .010–.014 | .012–.016 | .014–.018 | .016–.020 |

| 2 | 390 | 560 | 980 | IPR | .005–.007 | .006–.008 | .006–.010 | .008–.012 | .011–.015 | .013–.017 | .015–.019 | .017–.021 | |

| 3 | 330 | 490 | 980 | IPR | .005–.007 | .006–.008 | .006–.010 | .008–.012 | .011–.015 | .013–.017 | .015–.019 | .017–.021 | |

| 4 | 260 | 660 | 980 | IPR | .001–.002 | .001–.002 | .001–.002 | .002–.002 | .002–.003 | .002–.003 | .002–.003 | .002–.004 | |

|  | ||||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Malzeme grubu | Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | ||

| N | 1 | 120 | 200 | 300 | mm/dev | 0,12–0,17 | 0,13–0,18 | 0,15–0,24 | 0,19–0,29 | 0,26–0,35 | 0,31–0,40 | 0,35–0,45 | 0,41–0,51 |

| 2 | 120 | 170 | 300 | mm/dev | 0,13–0,18 | 0,14–0,19 | 0,16–0,25 | 0,20–0,30 | 0,28–0,37 | 0,33–0,42 | 0,38–0,48 | 0,44–0,54 | |

| 3 | 100 | 150 | 300 | mm/dev | 0,13–0,18 | 0,14–0,19 | 0,16–0,25 | 0,20–0,30 | 0,28–0,37 | 0,33–0,42 | 0,38–0,48 | 0,44–0,54 | |

| 4 | 80 | 200 | 300 | mm/dev | 0,03–0,05 | 0,03–0,06 | 0,03–0,06 | 0,04–0,06 | 0,05–0,07 | 0,05–0,08 | 0,05–0,08 | 0,06–0,09 | |

I have read and accepted the Terms & Conditions of use