Mill 1-14™ • Carbide Insert • EDCT-LD • Light Machining

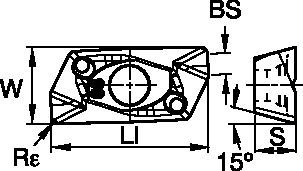

Shoulder milling insert with two cutting edges per insert, precision ground

物料号2983278

公制样本编号EDCT140408PDERLD英制样本编号EC1408ELD

- P 钢

- M 不锈钢

- K 铸铁

- S 高温合金

- H 淬火材料

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

| 物料号 | 2983278 |

| 公制样本编号 | EDCT140408PDERLD |

| 英制样本编号 | EC1408ELD |

| 材质 | KC522M |

| [LI] 刀片长度 | 17.5 mm |

| [LI] 刀片长度 | .689 in |

| [L10] 刀片切削刃长度 | 15.281 mm |

| [L10] 刀片切削刃长度 | .6016 in |

| [S] 刀片厚度 | 4.5 mm |

| [S] 刀片厚度 | .1772 in |

| [W] 刀片宽度 | 8.399 mm |

| [W] 刀片宽度 | .3307 in |

| [BS] 刀尖刃口长度 | 2.56 mm |

| [BS] 刀尖刃口长度 | .101 in |

| [Rε] 刀尖半径 | 3.1 mm |

| [Rε] 刀尖半径 | .122 in |

| 平均切屑厚度 [HM] | 0.038 mm |

| 平均切屑厚度 [HM] | .0015 in |

| 每个刀片的切削刃 | 2 |

工件材料

- 钢

- 不锈钢

- 铸铁

- 高温合金

- 淬火材料

Features and benefits

- Precision ground insert for best surface finish.

通过创建解决方案计算速度和进给

创建解决方案后,只需选择进给和速度图标,我们的系统将提供建议。您可以通过添加您的机床和参数来定制信息,或者使用滑块进行调整。

High Performance Combination Tools

刀片选择指南

| Malzeme grubu | Hafif işleme | Orta | Ağır işleme | |||

| P1–P2 | .E..GD | KCPM40 | .S..GD2 | KCPM40 | .E..HD2 | KCPM40 |

| P3–P4 | .E..GD | KCPM40 | .S..GD2 | KCPK30 | .E..HD2 | KCPK30 |

| P5–P6 | .E..GD | KC725M | .S..GD2 | KC725M | .E..HD2 | KC725M |

| M1–M2 | .E..LD | KC522M | .E..GD | KCSM40 | .E..HD2 | KC522M |

| M3 | .E..GD | KCSM40 | .S..GD2 | KCPM40 | .E..HD2 | KCPM40 |

| K1–K2 | .S..GD2 | KCK20B | .E..HD2 | KCK20B | .E..HD2 | KCK15 |

| K3 | .S..GD2 | KCK20B | .E..HD2 | KCK20B | .E..HD2 | KCK15 |

| N1–N2 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LDJ | KC422M |

| N3 | .F..LDJ | KC410M | .F..LDJ | KC410M | .E..LDJ | KC422M |

| S1–S2 | .E..GD | KC725M | .S..GD2 | KC725M | .E..HD2 | KC725M |

| S3 | .E..GD | KCSM40 | .S..GD2 | KC725M | .E..HD2 | KC725M |

| S4 | .E..GD | KCSM40 | .S..GD2 | KC725M | .E..HD2 | KC522M |

| H1 | – | – | – | – | – | – |

I have read and accepted the Terms & Conditions of use