Product Similar To:

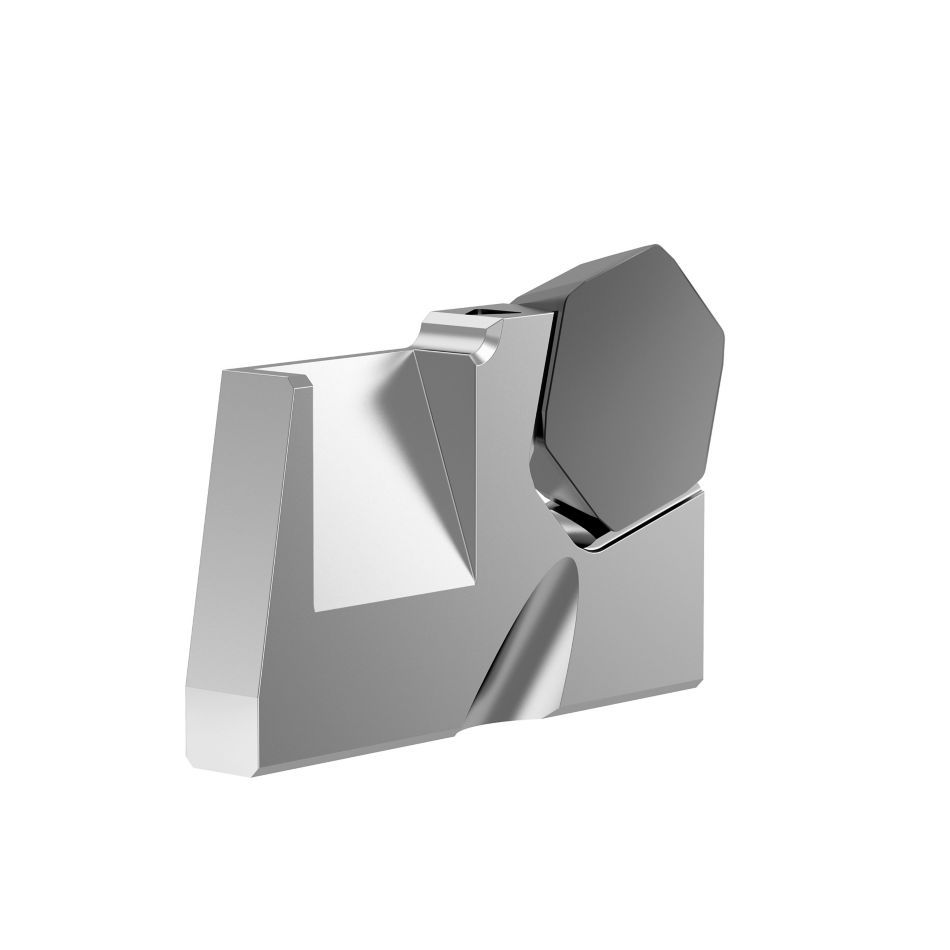

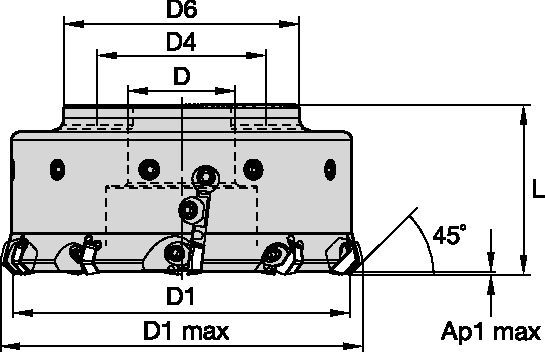

KCFM™ 45 • Shell Mill • Metric

Face Mill • Cast Iron Machining

Material Number6224239

ISO Catalog IDKCFM100R08HD07W2ANSI Catalog IDKCFM100R08HD07W2

- P Steel

- K Cast Iron

- N Non-Ferrous

- H Hardened Materials

Face Milling

Milling - Side and Face

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Overview

- Application Data

- Downloads

- Compatible Parts Machine Side

- Compatible Parts Workpiece Side

- Spare Parts

- Reviews

- Q&A

| Material Number | 6224239 |

| ISO Catalog ID | KCFM100R08HD07W2 |

| ANSI Catalog ID | KCFM100R08HD07W2 |

| [D1] Effective Cutting Diameter | 100 mm |

| [D1] Effective Cutting Diameter | 3.937 in |

| [D1MAX] Maximum Cutting Diameter | 109.53 mm |

| [D1MAX] Maximum Cutting Diameter | 4.312 in |

| [D] Adapter / Shank / Bore Diameter | 32 mm |

| [D] Adapter / Shank / Bore Diameter | 1.26 in |

| [D6] Hub Diameter | 101.4 mm |

| [D6] Hub Diameter | 3.992 in |

| [L] Overall Length | 49.97 mm |

| [L] Overall Length | 1.967 in |

| [AP1MAX] 1st Maximum Cutting Depth | 1.09 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .043 in |

| Number of Inserts | 8 |

| Number of Adjustable Inserts | 2 |

| Weight Kilograms | 2.41 |

| Max RPM | 8400 |

Workpiece Materials

- Steel

- Cast Iron

- Non-Ferrous

- Hardened Materials

Uses and application

Face Milling

Milling - Side and Face

Features and benefits

- Ap1 max = 1mm with wiper finishing cartridge for SD12 inserts.

- Ap1 max = 3mm with semi-finishing cartridge for HD07 inserts.

- Fixed pockets for semi-finishing inserts.

- Adjustable pockets for cartridges with finishing inserts or wiper inserts.

- Pocket seat numbering system for quick set-up time.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Feeds

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| -SR | 0,06 | 0,12 | -SR | |||||||||||||

| -ER | 0,10 | 0,18 | -ER | |||||||||||||

| Fine Finishing | Semi-Finishing | Roughing |

Speeds

| Material Group | KC514M | KBK50 | KY3500 | |||||||

| K | 1 | 950 | 625 | 445 | 3935 | 2625 | 1970 | 3165 | 2870 | 2560 |

| 2 | 740 | 525 | 375 | 3935 | 2625 | 1970 | 2495 | 2245 | 2085 | |

| 3 | 625 | 445 | 360 | 3935 | 2625 | 1970 | 2100 | 1870 | 1705 | |

| Material Group | KC514M | KBK50 | KY3500 | |||||||

| K | 1 | 760 | 500 | 355 | – | – | – | – | – | – |

| 2 | 590 | 420 | 300 | – | – | – | – | – | – | |

| 3 | 500 | 355 | 290 | – | – | – | – | – | – | |

Insert Selection

Insert Selection Guide

| – | Fine Finishing | Semi-Finishing | ||

| Material Group | Option 1: CBN | Option 2: Coated Carbide | Option 1: Advanced Material | Option 2: Coated Carbide |

| K1 | .S..R KBK50 | .E..R KC514M | .S..R KY3500/KBK50 | .E..R KC514M |

| K3 | – | .E..R KC514M | – | .E..R KC514M |

I have read and accepted the Terms & Conditions of use