High performance parts start with high performance materials

Kennametal is a global leader in the development and production of gas-atomized cobalt, nickel and iron-based alloy powders optimized for additive manufacturing. Our metal additive powders are field proven in a variety of additive processes, including powder bed fusion, direct energy deposition, and binder jet technology (BJT).

Metal additive manufacturing processes (metal 3D printing) represent the next generation in design freedom, manufacturing cost reduction, and supply chain optimization. These proven processes are being leveraged across a variety of industries and applications to develop and deploy high-performing parts both quickly and efficiently.

We offer our metal additive powders direct to customers for use in aerospace, oil and gas, automotive, energy, and medical 3D printing applications—or in combination with our end-to-end AM capabilities to produce fully-finished components and tooling.

AM Metal Powder Portfolio

Kennametal Stellite™ powders can be tailored to meet your particle size distribution requirements.

With superior process control, we achieve exceptional powder flowability and sphericity.

AM Metal Powder Applications

Our additive powder portfolio offers a range of metal powders with the material characteristics needed for use in industries such as aerospace, automotive, oil and gas, power generation, medical, dental, tool and die, and other general processing industries.

STELLITE™ Additive Powder

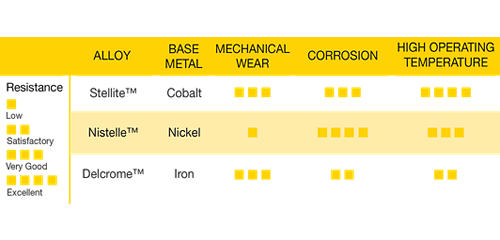

The cobalt-based Stellite™ alloys are some of the most well-known and successful alloys in the world, with outstanding “all-round” properties. They combine excellent mechanical wear resistance, especially at high temperatures, with good corrosion resistance. The Stellite™ alloys are mostly cobalt-based with additions of Cr, C, W, and/or Mo.

Nominal Composition (mass %)

Material | Co | Ni | Cr | W | Mo | C | Fe | Si | B | Others |

Stellite™ 6 | Bal. | -- | 28.5 | 4.6 | -- | 12 | -- | -- | -- | -- |

Stellite™ 21 | Bal. | 2.6 | 27.5 | -- | 5.4 | 0.3 | -- | -- | -- | -- |

NISTELLE™ Additive Powder

The nickel-based Nistelle™ alloys are designed to be corrosion resistant rather than wear resistant, particularly in aggressive chemical environments where their high chromium and molybdenum contents provide excellent pitting resistance. As a class, they are also generally resistant to high-temperature oxidation and hot gas corrosion.

Nominal Composition (mass %)

Material | Co | Ni | Cr | W | Mo | C | Fe | Si | B | Others |

Nistelle™ 625 | -- | Bal. | 21.5 | -- | 9.0 | -- | -- | -- | -- | -- |

Nistelle™ 718 | -- | Bal. | 21.5 | 3.0 | 13.5 | -- | 4.0 | -- | -- | -- |

DELCROME™ Additive Powder

The iron-based Delcrome™ alloys were developed to resist abrasive wear at lower temperatures, typically up to 200º C. These alloys also provide moderate corrosion resistance and metal to metal wear resistance.

Nominal Composition (mass %)

Material | Co | Ni | Cr | W | Mo | C | Fe | Si | B | Others |

Delcrome™ 316L | -- | 13.0 | 18.0 | -- | 2.6 | -- | Bal. | 1.8 | -- | -- |

Delcrome™ 17-4 | -- | 4.0 | 16.5 | -- | -- | -- | Bal. | 1.0 | -- | -- |

Delcrome™ H13 | -- | 0.3 | 5.0 | -- | 1.5 | 0.3 | Bal. | 1.0 | -- | -- |