A Slurry-Based, Wear-Resistant Surface Treatment from Kennametal

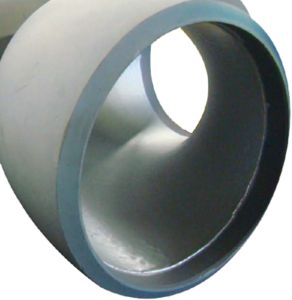

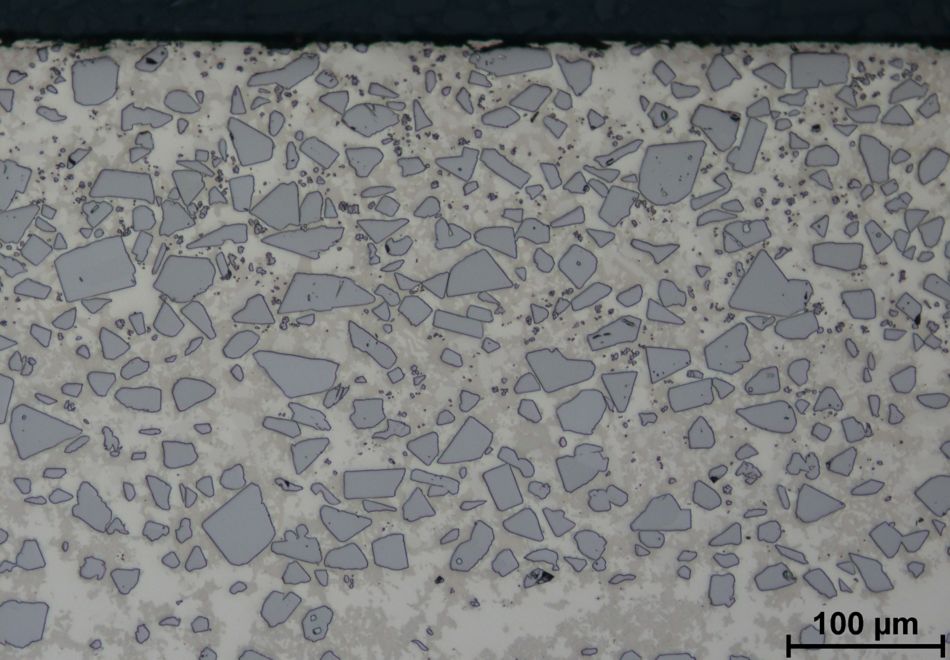

Available in both tungsten carbide (WC) and Stellite™ formulations, UltraFlex™ can be applied to a broad range of steel and nickel-based alloys. Ultraflex is a premium wear solution for cladding difficult geometries such as IDs and non-line-of-sight features that are difficult to protect with other hard facing solutions, such as weld overlays and thermal sprays.

Surface Quality

UltraFlex has a smooth to the touch surface quality that may benefit some applications. It is often used in petrochemical applications that involve multiple wear mechanisms.

In contrast to traditional welding, the UltraFlex process metallurgically brazes the wear system directly to the substrate in a vacuum furnace. This eliminates high localized heat and the associated heat affected zone (HAZ), essentially eliminating dilution of the cladding.