HexaCut™ 45° • Cast Iron

HexaCut 45° roughing and semi-finishing face milling operations are a terrific solution for use on cast and ductile iron materials as well CGI (Compacted Graphite Iron). Proven to be very effective in special automotive applications, the HexaCut milling platform can be a problem solver for difficult milling operations. Twelve cutting edges on each insert drastically reduce cost per edge and increase tool life. The comprehensive insert geometries match every application for light, medium, and heavy machining. Additionally, the 45° lead cutter bodies are engineered with fixed pockets for roughing applications up to Ap1 max = 6mm.

- P Steel (9)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(8)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(8)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(8)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(8)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(9)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(8)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(8)

- M Stainless Steel (8)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(8)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(8)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(8)

- K Cast Iron (35)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(34)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(34)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(35)

- N Non-Ferrous Materials (8)

- N1Wrought Aluminum (8)

- N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2%(8)

- N3High-Silicon Aluminum Alloys Si >12.2%(8)

- S High-Temp Alloys (8)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(8)

- H Hardened Materials (8)

- H1Hardened Materials 44-48 HRC(8)

Face Milling (7)

- 3.15 in(1)

- 3.938 in(1)

- 4.0 in(2)

- 4.921 in(1)

- 5.0 in(1)

- 6.299 in(1)

- 80.0 mm(1)

- 100.0 mm(1)

- 101.601 mm(2)

- 125.0 mm(1)

- 127.0 mm(1)

- 160.0 mm(1)

- 92.801 mm(1)

- 112.801 mm(1)

- 114.301 mm(2)

- 137.8 mm(1)

- 139.701 mm(1)

- 172.8 mm(1)

- 3.654 in(1)

- 4.441 in(1)

- 4.5 in(2)

- 5.425 in(1)

- 5.5 in(1)

- 6.803 in(1)

- 6.5 mm(7)

- 0.256 in(7)

- 1.969 in(2)

- 1.971 in(1)

- 2.0 in(1)

- 2.38 in(1)

- 2.48 in(2)

- 50.0 mm(2)

- 50.051 mm(1)

- 50.801 mm(1)

- 60.45 mm(1)

- 63.0 mm(2)

- 45.0 (7)

- A-Socket Head Cap Screw (3)

- B-Cutter Retention Screw (3)

- SHCS or RetScrw Or BoltCircle (1)

- 10 (1)

- 14 (2)

- 18 (2)

- 22 (1)

- 7 (1)

- 1.969 in(2)

- 1.971 in(1)

- 2.0 in(1)

- 2.38 in(1)

- 2.48 in(2)

- 50.0 mm(2)

- 50.051 mm(1)

- 50.801 mm(1)

- 60.45 mm(1)

- 63.0 mm(2)

- 0.0 in(10)

- 0.016 in(7)

- 0.031 in(9)

- 0.047 in(9)

- 0.063 in(16)

- 0.079 in(13)

- 0.119 in(13)

- 0.0 mm(10)

- 0.4 mm(7)

- 0.8 mm(9)

- 1.201 mm(9)

- 1.6 mm(16)

- 2.0 mm(13)

- 3.0 mm(13)

- KC514M (7)

- KC524M (8)

- KC907M (7)

- KC914M (7)

- KC917M (7)

- KC924M (7)

- KCK15 (17)

- KCK20B (18)

- KCKP10 (8)

- KCPK30 (8)

- KD200 (8)

- KY3500 (10)

- R (7)

- N (28)

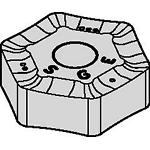

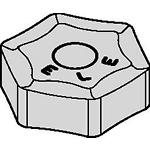

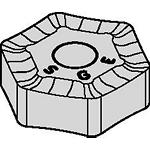

- H-HEXAGON 120 (28)

- 15.875 mm(3)

- 16.2 mm(25)

- 0.625 in(3)

- 0.638 in(25)

- 8.9 mm(2)

- 9.175 mm(3)

- 9.35 mm(23)

- 0.351 in(2)

- 0.361 in(3)

- 0.368 in(23)

- GE (16)

- LE (3)

- MCI (2)

- MH (1)

- MR (2)

- B L (1)

- C N (3)

- H W (24)

- E (4)

- G (3)

- H (12)

- P (9)

- SHELL MILL (7)

- 27.0 mm(1)

- 31.75 mm(2)

- 32.0 mm(1)

- 38.1 mm(1)

- 40.0 mm(2)

- 1.063 in(1)

- 1.25 in(2)

- 1.26 in(1)

- 1.5 in(1)

- 1.575 in(2)