Product Similar To:

KenCut™ MM • F2AL-WM • Ball Nose • 2 Flutes • Extended Neck • Long • Plain Shank • Metric

KenCut™ MM Solid Carbide End Mill for Finishing of Steels and Hard Materials

Material Number2657430

ISO Catalog IDF2AL0300AWM30E160ANSI Catalog IDF2AL0300AWM30E160

- P Steel

- H Hardened Materials

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Tool Dimensions: Flute Configuration: 2

Helix Angle: 30°

Corner Style: Ball Nose

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

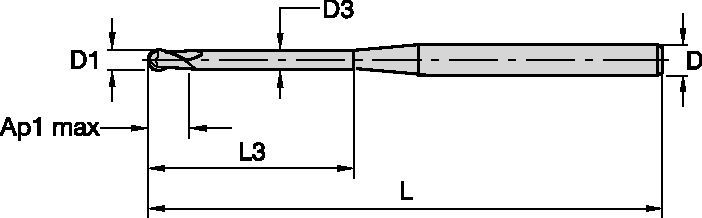

| Material Number | 2657430 |

| ISO Catalog ID | F2AL0300AWM30E160 |

| ANSI Catalog ID | F2AL0300AWM30E160 |

| Grade | KC639M |

| Adapter Style Machine Side | Straight-Cylindrical |

| [D1] Effective Cutting Diameter | 3 mm |

| [D1] Effective Cutting Diameter | .1181 in |

| [D] Adapter / Shank / Bore Diameter | 4 mm |

| [D] Adapter / Shank / Bore Diameter | .1575 in |

| [D3] Neck Diameter | 2.92 mm |

| [D3] Neck Diameter | .115 in |

| [AP1MAX] 1st Maximum Cutting Depth | 4.5 mm |

| [AP1MAX] 1st Maximum Cutting Depth | .1772 in |

| [L3] Usable Length | 16 mm |

| [L3] Usable Length | .6299 in |

| [L] Overall Length | 65 mm |

| [L] Overall Length | 2.559 in |

| [Z] Number of Flutes | 2 |

Workpiece Materials

- Steel

- Hardened Materials

Uses and application

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Tool Dimensions: Flute Configuration: 2

Helix Angle: 30°

Corner Style: Ball Nose

Grades

KC639M

PVD- (AlTiN) coated carbide on a submicron carbide substrate. This hard coating provides outstanding performance in milling hardened materials (58–65 HRC).

Features and benefits

- Centre cutting for plunging and ramping operations.

- Solid carbide end mill for micro machining and small parts machining.

- Solid carbide end mill for machining of steels and hardened steels up to 67HRC.

Create Solution to calculate Feeds and Speeds

After creating a solution just choose the Feeds & Speeds icon and our system will provide recommendations. You can customize the information by adding your machine and specifications or make adjustments using the sliders.

Tolerance

| End Mill Tolerances | |||

| D1 | tolerance e8 | D | tolerance h6 + / - |

| ≤3 | -0,014/-0,028 | ≤3 | +0/-0,006 |

| -0,020/-0,038 | +0/-0,008 | ||

| -0,025/-0,047 | +0/-0,009 | ||

| -0,032/-0,059 | +0/-0,011 | ||

| -0,040/-0,073 | +0/-0,013 | ||

Speeds & Feeds

|  | ||||||||||||||||

| Profiling | KC639M | Feed per Tooth — Roughing (A). | |||||||||||||||

| A | Cutting Speed | D1 | |||||||||||||||

| Material | ap | ae | Min | Max | mm | 0,3 | 0,4 | 0,5 | 0,6 | 0,8 | 1,0 | 1,5 | 2,0 | 2,5 | 3,0 | 4,0 | |

| P | 3 | 0,2 x D | 0,1 x D | 187 | 211 | fz | 0,0022 | 0,0030 | 0,0037 | 0,0044 | 0,0059 | 0,0075 | 0,0113 | 0,0152 | 0,0192 | 0,0232 | 0,0309 |

| 4 | 0,2 x D | 0,1 x D | 164 | 187 | fz | 0,0021 | 0,0028 | 0,0035 | 0,0042 | 0,0056 | 0,0070 | 0,0105 | 0,0141 | 0,0177 | 0,0213 | 0,0285 | |

| 1 | 0,15 x D | 0,1 x D | 126 | 176 | fz | 0,0031 | 0,0041 | 0,0052 | 0,0062 | 0,0083 | 0,0104 | 0,0157 | 0,0211 | 0,0265 | 0,0319 | 0,0426 | |

| H | 2 | 0,1 x D | 0,075 x D | 107 | 184 | fz | 0,0035 | 0,0047 | 0,0059 | 0,0070 | 0,0094 | 0,0118 | 0,0178 | 0,0238 | 0,0299 | 0,0360 | 0,0480 |

| 3 | 0,05 x D | 0,05 x D | 124 | 186 | fz | 0,0040 | 0,0053 | 0,0066 | 0,0080 | 0,0106 | 0,0133 | 0,0201 | 0,0269 | 0,0338 | 0,0408 | 0,0544 | |

| 4 | 0,05 x D | 0,05 x D | 104 | 145 | fz | 0,0027 | 0,0035 | 0,0044 | 0,0053 | 0,0071 | 0,0089 | 0,0134 | 0,0179 | 0,0226 | 0,0272 | 0,0362 | |

|  | ||||||||||||||||

| Profiling | KC639M | Feed per Tooth — Semi-Finishing (A). | |||||||||||||||

| A | Cutting Speed | D1 | |||||||||||||||

| Material | ap | ae | Min | Max | mm | 0,3 | 0,4 | 0,5 | 0,6 | 0,8 | 1,0 | 1,5 | 2,0 | 2,5 | 3,0 | 4,0 | |

| P | 3 | 0,1 x D | 0,05 x D | 245 | 275 | fz | 0,0050 | 0,0066 | 0,0083 | 0,0099 | 0,0133 | 0,0167 | 0,0253 | 0,0339 | 0,0428 | 0,0518 | 0,0690 |

| 4 | 0,1 x D | 0,05 x D | 214 | 245 | fz | 0,0046 | 0,0062 | 0,0077 | 0,0093 | 0,0124 | 0,0155 | 0,0235 | 0,0314 | 0,0396 | 0,0477 | 0,0636 | |

| 1 | 0,07 x D | 0,1 x D | 180 | 252 | fz | 0,0058 | 0,0077 | 0,0097 | 0,0116 | 0,0155 | 0,0194 | 0,0294 | 0,0393 | 0,0495 | 0,0596 | 0,0795 | |

| H | 2 | 0,05 x D | 0,04 x D | 145 | 248 | fz | 0,0050 | 0,0067 | 0,0084 | 0,0101 | 0,0135 | 0,0169 | 0,0255 | 0,0342 | 0,0430 | 0,0518 | 0,0690 |

| 3 | 0,03 x D | 0,03 x D | 157 | 235 | fz | 0,0045 | 0,0061 | 0,0076 | 0,0091 | 0,0122 | 0,0152 | 0,0230 | 0,0308 | 0,0387 | 0,0466 | 0,0621 | |

| 4 | 0,03 x D | 0,03 x D | 131 | 183 | fz | 0,0030 | 0,0040 | 0,0051 | 0,0061 | 0,0081 | 0,0102 | 0,0153 | 0,0205 | 0,0258 | 0,0311 | 0,0414 | |

|  | ||||||||||||||||

| Profiling | KC639M | Feed per Tooth — Finishing (A). | |||||||||||||||

| A | Cutting Speed | D1 | |||||||||||||||

| Material | ap | ae | Min | Max | mm | 0,3 | 0,4 | 0,5 | 0,6 | 0,8 | 1,0 | 1,5 | 2,0 | 2,5 | 3,0 | 4,0 | |

| P | 3 | 0,04 x D | 0,04 x D | 374 | 421 | fz | 0,0076 | 0,0102 | 0,0127 | 0,0153 | 0,0204 | 0,0256 | 0,0389 | 0,0522 | 0,0659 | 0,0796 | 0,1062 |

| 4 | 0,04 x D | 0,04 x D | 328 | 374 | fz | 0,0071 | 0,0095 | 0,0119 | 0,0143 | 0,0191 | 0,0239 | 0,0361 | 0,0484 | 0,0609 | 0,0734 | 0,0979 | |

| 1 | 0,03 x D | 0,03 x D | 261 | 365 | fz | 0,0076 | 0,0102 | 0,0127 | 0,0153 | 0,0204 | 0,0255 | 0,0386 | 0,0517 | 0,0650 | 0,0784 | 0,1045 | |

| H | 2 | 0,03 x D | 0,03 x D | 183 | 313 | fz | 0,0058 | 0,0077 | 0,0096 | 0,0116 | 0,0154 | 0,0193 | 0,0292 | 0,0391 | 0,0491 | 0,0592 | 0,0789 |

| 3 | 0,02 x D | 0,02 x D | 194 | 292 | fz | 0,0049 | 0,0065 | 0,0081 | 0,0097 | 0,0130 | 0,0163 | 0,0245 | 0,0328 | 0,0413 | 0,0497 | 0,0663 | |

| 4 | 0.02 x D | 0,02 x D | 162 | 227 | fz | 0,0032 | 0,0043 | 0,0054 | 0,0065 | 0,0087 | 0,0108 | 0,0164 | 0,0219 | 0,0275 | 0,0331 | 0,0442 | |

I have read and accepted the Terms & Conditions of use