Wear. A Small Word That Describes a Big Problem.

Wear translates to expensive equipment repair and replacement costs and can cause significant downtime.

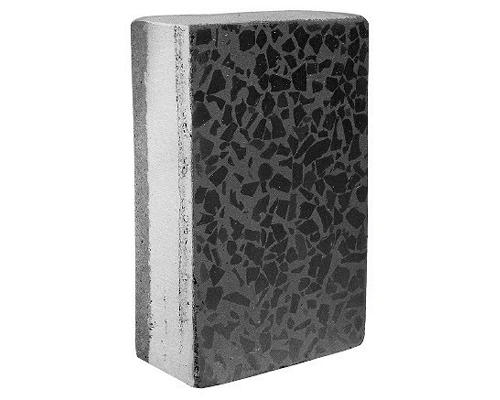

At Kennametal, we understand the importance of preventing wear damage to your equipment. That’s why our wear experts developed KenCast. KenCast helps equipment last longer, whether you’re working above ground or underground, on the road or in the pit, crushing rock or pushing snow. With KenCast protection, you can avoid costly repairs and downtime.

KenCast wear parts are proven to withstand extreme abrasive and high-impact applications. KenCast is extremely versatile and can fit nearly any machine for nearly any application. It is easily welded or attached mechanically into position.