Produkt ähnlich wie:

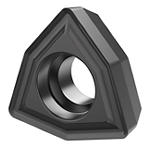

DFSP Schaft mit Flansch • Rechte Ausführung • 2 x D

Drill Fix™ DFSP™ Werkzeugkörper

Material Nummer5689602

ISO Katalog NummerDFSP0563R2SSF075ANSI Katalog NummerDFSP0563R2SSF075

- P Stahl

- M Rostfreier Stahl

- K Gusseisen

- N NE-Metalle

- S Hochwarmfeste Legierungen

Bohren

Bohren: Schräge Eintrittsfläche

Bohren: Schräge Austrittsfläche

Bohren: X-Verstellung

Bohren: Konvexe Eintrittsfläche

Zylinderschaft – mit Spannfläche und Flansch

Innere Kühlmittelzuführung: Radial: Bohren mit Wendeschneidplatten

Bohren: Sacklochbohrung

Chain Drilling

Drilling: Cross-Hole Drilling

Drilling: Half-Cylindrical Drilling

Drilling: Corner Drilling 45°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Überblick

- Anwendungsdaten

- Herunterladen

- Kompatible Teile Maschinenseite

- Kompatible Teile Werkstückseite

- Ersatzteile

- Bewertung

- F&A

| Material Nummer | 5689602 |

| ISO Katalog Nummer | DFSP0563R2SSF075 |

| ANSI Katalog Nummer | DFSP0563R2SSF075 |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 19.05 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | .75 in |

| [D1] Bohrerdurchmesser M | 14.3 mm |

| [D1] Bohrerdurchmesser M | .5625 in |

| [D1MAX] Bohrerdurchmesser max. | 15.301 mm |

| [D1MAX] Bohrerdurchmesser max. | .6024 in |

| [L1] Messlänge der Wendeschneidplatte | 52.37 mm |

| [L1] Messlänge der Wendeschneidplatte | 2.061 in |

| [L4] Maximale Bohrtiefe | 28.6 mm |

| [L4] Maximale Bohrtiefe | 1.126 in |

| [L5] Bohrerspitzenlänge | 0.35 mm |

| [L5] Bohrerspitzenlänge | .0138 in |

| [LS] Schaftlänge | 50.8 mm |

| [LS] Schaftlänge | 2 in |

| [CF] Kühlmittel radiale Größe | 1/8 - 27 NPT |

| [CS] Kühlmittelzufuhrgröße | 1/8 - 27 NPT |

| Wendeschneidplatten-Größe | SPGX0502. |

| Maß-Wendeschneidplatte 2 | DFTX202. |

Werkstoffe

- Stahl

- Rostfreier Stahl

- Gusseisen

- NE-Metalle

- Hochwarmfeste Legierungen

Uses and application

Bohren

Bohren: Schräge Eintrittsfläche

Bohren: Schräge Austrittsfläche

Bohren: X-Verstellung

Bohren: Konvexe Eintrittsfläche

Zylinderschaft – mit Spannfläche und Flansch

Innere Kühlmittelzuführung: Radial: Bohren mit Wendeschneidplatten

Bohren: Sacklochbohrung

Chain Drilling

Drilling: Cross-Hole Drilling

Drilling: Half-Cylindrical Drilling

Drilling: Corner Drilling 45°

Features and benefits

- DFSP vereint die wirtschaftliche quadratische Form der außen angeordneten Wendeschneidplatte mit den überlegenen Zentriereigenschaften der innen angeordneten Trigon-Wendeschneidplatte.

- Bohrer wird mit Wendeschneidplatten-Spannschrauben, Seitenrohrverschluss und Torxschlüssel geliefert.

- Wendeschneidplatten für DFSP müssen getrennt bestellt werden. Für Wendeschneidplatten siehe Seiten XX–XX.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Warnung

WARNUNG • Drill Fix DFR

| WARNUNG! Beim Austritt des Bohrers aus dem Werkstück entsteht eine Federscheibe. Bei drehendem Werkstück wird die Scheibe vom Werkstück weggeschleudert! Entsprechende Sicherheitsvorkehrungen sind erforderlich! |

Dimension

| ||||

| D | LS | CF | CS | Rohrverschlußstopfen |

| 0.750 | 2.00 | 1/8-27 NPT | R 1/8-27 NPT | 1025612 |

| 1.000 | 3.00 | 1/8-27 NPT | R 1/4-18 NPT | 1025612 |

| 1.250 | 3.25 | 1/8-27 NPT | R 1/4-18 NPT | 1025612 |

| 1.500 | 3.75 | 1/8-27 NPT | R 1/4-18 NPT | 1025612 |

| 2.000 | 4.00 | 1/8-27 NPT | R 1/4-18 NPT | 1025612 |

Anwendungsdaten

| Zoll | |||||||||||||||

| Werkstoffgruppe | Schnitt- bedingung | Plattensitz | Geometrie | Sorte | Schnittgeschwindigkeit | Empfohlene Vorschubrate (fz) pro Durchmesser | |||||||||

| Bereich | |||||||||||||||

| Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | ||||||

| P | 1 | S | O | MD | KCPK10 | 1017 | 1066 | 1181 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 656 | 705 | 754 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 426 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | MD | KCPK10 | 1017 | 1066 | 1181 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 656 | 705 | 754 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 426 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | MD | KCPK10 | 853 | 935 | 1050 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| I | MD | KC7140 | |||||||||||||

| U | O | FP | KCU25 | 590 | 640 | 722 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 361 | 394 | 459 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| 4 | S | O | FP | KCPK10 | 722 | 820 | 984 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU25 | 492 | 590 | 722 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 295 | 361 | 459 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| 5 | S | O | HP | KCU25 | 590 | 656 | 722 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 394 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 230 | 279 | 328 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| 6 | S | O | HP | KCU25 | 590 | 656 | 722 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 394 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 230 | 279 | 328 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | MD | KC7140 | |||||||||||||

| Zoll | |||||||||||||||

| Schnittgeschwindigkeit | |||||||||||||||

| Bereich | Empfohlene Vorschubrate (fz) pro Durchmesser | ||||||||||||||

| Werkstoffgruppe | Schnitt– bedingung | Plattensitz | Geometrie | Sorte | Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | |

| P | 1 | S | O | MD | KCPK10 | 1017 | 1066 | 1181 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 |

| 1 | S | I | MD | KC7140 | 1017 | 1066 | 1181 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 1 | U | O | FP | KCU25 | 656 | 705 | 754 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 1 | U | I | MD | KC7140 | 656 | 705 | 754 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 1 | I | O | HP | KCU40 | 426 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 1 | I | I | MD | KC7140 | 426 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 2 | S | O | MD | KCPK10 | 1017 | 1066 | 1181 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 2 | S | I | MD | KC7140 | 1017 | 1066 | 1181 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 2 | U | O | FP | KCU25 | 656 | 705 | 754 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 2 | U | I | MD | KC7140 | 656 | 705 | 754 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 2 | I | O | HP | KCU40 | 426 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 2 | I | I | MD | KC7140 | 426 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 3 | S | O | MD | KCPK10 | 853 | 935 | 1050 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 3 | S | I | MD | KC7140 | 853 | 935 | 1050 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 3 | U | O | FP | KCU25 | 590 | 640 | 722 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 3 | U | I | MD | KC7140 | 590 | 640 | 722 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 3 | I | O | HP | KCU40 | 361 | 394 | 459 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 3 | I | I | MD | KC7140 | 361 | 394 | 459 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 4 | S | O | FP | KCPK10 | 722 | 820 | 984 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 4 | S | I | MD | KC7140 | 722 | 820 | 984 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 4 | U | O | HP | KCU25 | 492 | 590 | 722 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 4 | U | I | MD | KC7140 | 492 | 590 | 722 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 4 | I | O | HP | KCU40 | 295 | 361 | 459 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 4 | I | I | MD | KC7140 | 295 | 361 | 459 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 5 | S | O | HP | KCU25 | 590 | 656 | 722 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 5 | S | I | MD | KC7140 | 590 | 656 | 722 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 5 | U | O | HP | KCU40 | 394 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 5 | U | I | MD | KC7140 | 394 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 5 | I | O | HP | KC7140 | 230 | 279 | 328 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 5 | I | I | MD | KC7140 | 230 | 279 | 328 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 6 | S | O | HP | KCU25 | 590 | 656 | 722 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 6 | S | I | MD | KC7140 | 590 | 656 | 722 | SFM | 0.0024–0.0043 | 0.0031–0.0055 | 0.0039–0.0071 | 0.0055–0.0098 | 0.0063–0.0118 | 0.0071–0.0118 | |

| 6 | U | O | HP | KCU40 | 394 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 6 | U | I | MD | KC7140 | 394 | 443 | 492 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 6 | I | O | HP | KC7140 | 230 | 279 | 328 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 6 | I | I | MD | KC7140 | 230 | 279 | 328 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| Zoll | |||||||||||||||

| Werkstoffgruppe | Schnitt- bedingung | Plattensitz | Geometrie | Sorte | Schnittgeschwindigkeit | Empfohlene Vorschubrate (fz) pro Durchmesser | |||||||||

| Bereich | |||||||||||||||

| Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | ||||||

| M | 1 | S | O | FP | KCU25 | 492 | 623 | 754 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KCU40 | 328 | 426 | 525 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0079 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 197 | 262 | 328 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0071 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | FP | KCU25 | 492 | 590 | 689 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| I | MD | KC7140 | |||||||||||||

| U | O | MD | KCU40 | 328 | 426 | 525 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0079 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 197 | 262 | 328 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0071 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | HP | KCU25 | 328 | 426 | 525 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 262 | 361 | 459 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0079 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | MD | KC7140 | 164 | 230 | 295 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0071 | ||

| I | MD | KC7140 | |||||||||||||

| Zoll | |||||||||||||||

| Schnittgeschwindigkeit | |||||||||||||||

| Bereich | Empfohlene Vorschubrate (fz) pro Durchmesser | ||||||||||||||

| Werkstoffgruppe | Schnitt– bedingung | Plattensitz | Geometrie | Sorte | Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | |

| M | 1 | S | O | FP | KCU25 | 492 | 623 | 754 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 |

| 1 | S | I | MD | KC7140 | 492 | 623 | 754 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 1 | U | O | MD | KCU40 | 328 | 426 | 525 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0079 | |

| 1 | U | I | MD | KC7140 | 328 | 426 | 525 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0079 | |

| 1 | I | O | MD | KC7140 | 197 | 262 | 328 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0071 | |

| 1 | I | I | MD | KC7140 | 197 | 262 | 328 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0071 | |

| 2 | S | O | FP | KCU25 | 492 | 590 | 689 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 2 | S | I | MD | KC7140 | 492 | 590 | 689 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 2 | U | O | MD | KCU40 | 328 | 426 | 525 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0079 | |

| 2 | U | I | MD | KC7140 | 328 | 426 | 525 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0079 | |

| 2 | I | O | MD | KC7140 | 197 | 262 | 328 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0071 | |

| 2 | I | I | MD | KC7140 | 197 | 262 | 328 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0071 | |

| 3 | S | O | HP | KCU25 | 328 | 426 | 525 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 3 | S | I | HP | KC7140 | 328 | 426 | 525 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 3 | U | O | HP | KCU40 | 262 | 361 | 459 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0079 | |

| 3 | U | I | HP | KC7140 | 262 | 361 | 459 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0079 | |

| 3 | I | O | MD | KC7140 | 164 | 230 | 295 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0071 | |

| 3 | I | I | MD | KC7140 | 164 | 230 | 295 | SFM | 0.0012–0.0020 | 0.0016–0.0028 | 0.0020–0.0035 | 0.0028–0.0051 | 0.0031–0.0063 | 0.0039–0.0071 | |

| Zoll | |||||||||||||||

| Werkstoffgruppe | Schnitt- bedingung | Plattensitz | Geometrie | Sorte | Schnittgeschwindigkeit | Empfohlene Vorschubrate (fz) pro Durchmesser | |||||||||

| Bereich | |||||||||||||||

| Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | ||||||

| K | 1 | S | O | FP | KCPK10 | 656 | 787 | 984 | SFM | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 |

| I | HP | KCU40 | |||||||||||||

| U | O | FP | KCU25 | 394 | 508 | 656 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | FP | KC7140 | 262 | 328 | 410 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | HP | KC7140 | |||||||||||||

| 2 | S | O | FP | KCPK10 | 590 | 722 | 853 | SFM | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 361 | 459 | 558 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 262 | 328 | 394 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | HP | KC7140 | |||||||||||||

| 3 | S | O | HP | KCPK10 | 590 | 722 | 853 | SFM | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| I | HP | KCU40 | |||||||||||||

| U | O | HP | KCU25 | 361 | 459 | 558 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KC7140 | 262 | 328 | 394 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | HP | KC7140 | |||||||||||||

| Zoll | |||||||||||||||

| Schnittgeschwindigkeit | |||||||||||||||

| Bereich | Empfohlene Vorschubrate (fz) pro Durchmesser | ||||||||||||||

| Werkstoffgruppe | Schnitt– bedingung | Plattensitz | Geometrie | Sorte | Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | |

| K | 1 | S | O | FP | KCPK10 | 656 | 787 | 984 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 |

| 1 | S | I | HP | KCU40 | 656 | 787 | 984 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 1 | U | O | FP | KCU25 | 394 | 508 | 656 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 1 | U | I | HP | KC7140 | 394 | 508 | 656 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 1 | I | O | FP | KC7140 | 262 | 328 | 410 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 1 | I | I | HP | KC7140 | 262 | 328 | 410 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 2 | S | O | FP | KCPK10 | 590 | 722 | 853 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 2 | S | I | HP | KCU40 | 590 | 722 | 853 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 2 | U | O | HP | KCU25 | 361 | 459 | 558 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 2 | U | I | HP | KC7140 | 361 | 459 | 558 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 2 | I | O | HP | KC7140 | 262 | 328 | 394 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 2 | I | I | HP | KC7140 | 262 | 328 | 394 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 3 | S | O | HP | KCPK10 | 590 | 722 | 853 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 3 | S | I | HP | KCU40 | 590 | 722 | 853 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 3 | U | O | HP | KCU25 | 361 | 459 | 558 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 3 | U | I | HP | KC7140 | 361 | 459 | 558 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 3 | I | O | HP | KC7140 | 262 | 328 | 394 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 3 | I | I | HP | KC7140 | 262 | 328 | 394 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| Zoll | |||||||||||||||

| Werkstoffgruppe | Schnitt- bedingung | Plattensitz | Geometrie | Sorte | Schnittgeschwindigkeit | Empfohlene Vorschubrate (fz) pro Durchmesser | |||||||||

| Bereich | |||||||||||||||

| Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | ||||||

| N | 1 | S | O | HP | KCPK10 | 1148 | 1640 | 2132 | SFM | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 |

| I | HP | KMF | |||||||||||||

| U | O | HP | KCU40 | 984 | 1312 | 1640 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | ||

| I | HP | KMF | |||||||||||||

| I | O | HP | KCU40 | 656 | 984 | 1312 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | HP | KMF | |||||||||||||

| 2 | S | O | HP | KCPK10 | 984 | 1312 | 1640 | SFM | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| I | HP | KMF | |||||||||||||

| U | O | HP | KCU40 | 820 | 1148 | 1476 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | ||

| I | HP | KMF | |||||||||||||

| I | O | HP | KCU40 | 574 | 820 | 1066 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | HP | KMF | |||||||||||||

| 3 | S | O | HP | KCPK10 | 984 | 1312 | 1640 | SFM | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| I | HP | KMF | |||||||||||||

| U | O | HP | KCU40 | 820 | 1148 | 1476 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | ||

| I | HP | KMF | |||||||||||||

| I | O | HP | KCU40 | 492 | 820 | 1148 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | HP | KMF | |||||||||||||

| 4 | S | O | HP | KCU25 | 984 | 1312 | 1640 | SFM | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| I | HP | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 820 | 1148 | 1476 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | ||

| I | HP | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 656 | 984 | 1312 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | HP | KC7140 | |||||||||||||

| 5 | S | O | HP | KCU40 | 1312 | 1476 | 1640 | SFM | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| I | HP | KMF | |||||||||||||

| U | O | HP | KCU40 | 820 | 1148 | 1476 | SFM | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | ||

| I | HP | KMF | |||||||||||||

| I | O | HP | KCU40 | 656 | 984 | 1312 | SFM | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | ||

| I | HP | KMF | |||||||||||||

| Zoll | |||||||||||||||

| Schnittgeschwindigkeit | |||||||||||||||

| Bereich | Empfohlene Vorschubrate (fz) pro Durchmesser | ||||||||||||||

| Werkstoffgruppe | Schnitt– bedingung | Plattensitz | Geometrie | Sorte | Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | |

| N | 1 | S | O | HP | KCPK10 | 1148 | 1640 | 2132 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 |

| 1 | S | I | HP | KMF | 1148 | 1640 | 2132 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 1 | U | O | HP | KCU40 | 984 | 1312 | 1640 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 1 | U | I | HP | KMF | 984 | 1312 | 1640 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 1 | I | O | HP | KCU40 | 656 | 984 | 1312 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 1 | I | I | HP | KMF | 656 | 984 | 1312 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 2 | S | O | HP | KCPK10 | 984 | 1312 | 1640 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 2 | S | I | HP | KMF | 984 | 1312 | 1640 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 2 | U | O | HP | KCU40 | 820 | 1148 | 1476 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 2 | U | I | HP | KMF | 820 | 1148 | 1476 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 2 | I | O | HP | KCU40 | 574 | 820 | 1066 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 2 | I | I | HP | KMF | 574 | 820 | 1066 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 3 | S | O | HP | KCPK10 | 984 | 1312 | 1640 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 3 | S | I | HP | KMF | 984 | 1312 | 1640 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 3 | U | O | HP | KCU40 | 820 | 1148 | 1476 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 3 | U | I | HP | KMF | 820 | 1148 | 1476 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 3 | I | O | HP | KCU40 | 492 | 820 | 1148 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 3 | I | I | HP | KMF | 492 | 820 | 1148 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 4 | S | O | HP | KCU25 | 984 | 1312 | 1640 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 4 | S | I | HP | KC7140 | 984 | 1312 | 1640 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 4 | U | O | HP | KCU40 | 820 | 1148 | 1476 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 4 | U | I | HP | KC7140 | 820 | 1148 | 1476 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 4 | I | O | HP | KCU40 | 656 | 984 | 1312 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 4 | I | I | HP | KC7140 | 656 | 984 | 1312 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 5 | S | O | HP | KCU40 | 1312 | 1476 | 1640 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 5 | S | I | HP | KMF | 1312 | 1476 | 1640 | sfm | 0.0028–0.0047 | 0.0039–0.0063 | 0.0047–0.0079 | 0.0063–0.0110 | 0.0071–0.0126 | 0.0079–0.0134 | |

| 5 | U | O | HP | KCU40 | 820 | 1148 | 1476 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 5 | U | I | HP | KMF | 820 | 1148 | 1476 | sfm | 0.0020–0.0035 | 0.0024–0.0047 | 0.0031–0.0059 | 0.0047–0.0079 | 0.0055–0.0098 | 0.0063–0.0110 | |

| 5 | I | O | HP | KCU40 | 656 | 984 | 1312 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| 5 | I | I | HP | KMF | 656 | 984 | 1312 | sfm | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | 0.0035–0.0059 | 0.0043–0.0071 | 0.0051–0.0098 | |

| Zoll | |||||||||||||||

| Werkstoffgruppe | Schnitt- bedingung | Plattensitz | Geometrie | Sorte | Schnittgeschwindigkeit | Empfohlene Vorschubrate (fz) pro Durchmesser | |||||||||

| Bereich | |||||||||||||||

| Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | ||||||

| S | 1 | S | O | HP | KCU40 | 197 | 230 | 246 | SFM | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 131 | 164 | 197 | SFM | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 82 | 98 | 131 | SFM | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | ||

| I | MD | KC7140 | |||||||||||||

| 2 | S | O | HP | KCU40 | 164 | 197 | 230 | SFM | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 98 | 131 | 164 | SFM | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 82 | 98 | 131 | SFM | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | ||

| I | MD | KC7140 | |||||||||||||

| 3 | S | O | HP | KCU40 | 230 | 262 | 295 | SFM | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 164 | 197 | 230 | SFM | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 98 | 131 | 164 | SFM | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | ||

| I | MD | KC7140 | |||||||||||||

| 4 | S | O | HP | KCU40 | 230 | 262 | 295 | SFM | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| I | MD | KC7140 | |||||||||||||

| U | O | HP | KCU40 | 164 | 197 | 230 | SFM | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | ||

| I | MD | KC7140 | |||||||||||||

| I | O | HP | KCU40 | 98 | 131 | 164 | SFM | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | ||

| I | MD | KC7140 | |||||||||||||

| Zoll | |||||||||||||||

| Schnittgeschwindigkeit | |||||||||||||||

| Bereich | Empfohlene Vorschubrate (fz) pro Durchmesser | ||||||||||||||

| Werkstoffgruppe | Schnitt– bedingung | Plattensitz | Geometrie | Sorte | Min. | Startwert | Max. | Ø | SPGX05 DFTX2 .563–.688 | SPGX06 DFT03 .703–.844 | SPGX07 DFT05 .875–1.000 | SPGX09 DFT05 1.025–1.250 | SPGX12 DFT06/..07 1.313–1.656 | SPGX15 DFT07/..09 1.688–2.125 | |

| S | 1 | S | O | HP | KCU40 | 197 | 230 | 246 | sfm | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 |

| 1 | S | I | MD | KC7140 | 197 | 230 | 246 | sfm | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| 1 | U | O | HP | KCU40 | 131 | 164 | 197 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 1 | U | I | MD | KC7140 | 131 | 164 | 197 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 1 | I | O | HP | KCU40 | 82 | 98 | 131 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 1 | I | I | MD | KC7140 | 82 | 98 | 131 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 2 | S | O | HP | KCU40 | 164 | 197 | 230 | sfm | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| 2 | S | I | MD | KC7140 | 164 | 197 | 230 | sfm | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| 2 | U | O | HP | KCU40 | 98 | 131 | 164 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 2 | U | I | MD | KC7140 | 98 | 131 | 164 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 2 | I | O | HP | KCU40 | 82 | 98 | 131 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 2 | I | I | MD | KC7140 | 82 | 98 | 131 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 3 | S | O | HP | KCU40 | 230 | 262 | 295 | sfm | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| 3 | S | I | MD | KC7140 | 230 | 262 | 295 | sfm | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| 3 | U | O | HP | KCU40 | 164 | 197 | 230 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 3 | U | I | MD | KC7140 | 164 | 197 | 230 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 3 | I | O | HP | KCU40 | 98 | 131 | 164 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 3 | I | I | MD | KC7140 | 98 | 131 | 164 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 4 | S | O | HP | KCU40 | 230 | 262 | 295 | sfm | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| 4 | S | I | MD | KC7140 | 230 | 262 | 295 | sfm | 0.0012–0.0024 | 0.0016–0.0031 | 0.0020–0.0039 | 0.0031–0.0047 | 0.0039–0.0059 | 0.0047–0.0071 | |

| 4 | U | O | HP | KCU40 | 164 | 197 | 230 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 4 | U | I | MD | KC7140 | 164 | 197 | 230 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 4 | I | O | HP | KCU40 | 98 | 131 | 164 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

| 4 | I | I | MD | KC7140 | 98 | 131 | 164 | sfm | 0.0008–0.0012 | 0.0008–0.0016 | 0.0012–0.0020 | 0.0016–0.0024 | 0.0020–0.0031 | 0.0024–0.0039 | |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use