Produkt ähnlich wie:

T651 • Metrisch DIN 376 • Form C-Anschnitt • Für Windenergie-Bauteile

Beyond™ HSS-E-PM Gewindebohrer • Sacklochbohrungen

Material Nummer4153884

ISO Katalog NummerT651M240X300R6HX-D6ANSI Katalog NummerT651M240X300R6HX-D6

- P Stahl

Gewindedrehen: Sacklochbohrung

Toleranzklasse: 6HX

DIN 376

Anschnitt Form C (2–3)

HSS-E-PM

Innere Kühlmittelzuführung: Axial: Gewindebohren

Herstellerspezifikationen: M

Spiralwinkel Gewindebohrer: 15°

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

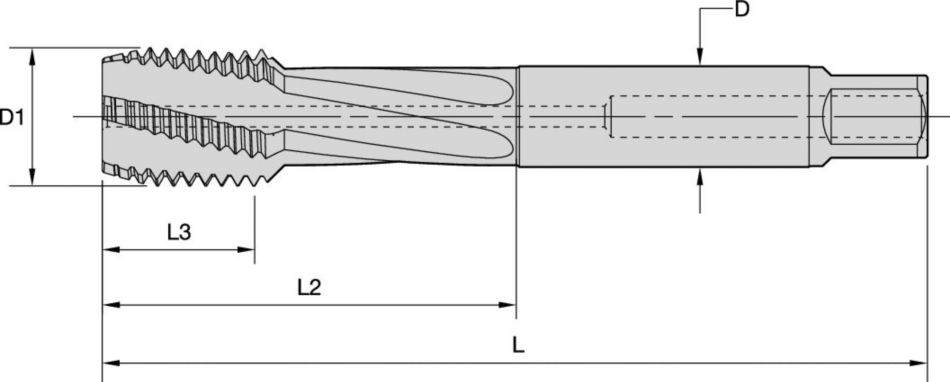

| Material Nummer | 4153884 |

| ISO Katalog Nummer | T651M240X300R6HX-D6 |

| ANSI Katalog Nummer | T651M240X300R6HX-D6 |

| Sorte | KP6525 |

| [D1-TDZ] Gewindedurchmessergröße | M24 X 3 |

| [L] Gesamtlänge | 160 mm |

| [L] Gesamtlänge | 6.3 in |

| [L3] Gewindelänge | 30 mm |

| [L3] Gewindelänge | 1.18 in |

| [L2] Nutzbare Länge | 77 mm |

| [L2] Nutzbare Länge | 3.03 in |

| [D] Adapter/Schaft/Bohrungsdurchmesser | 18 mm |

| [D] Adapter/Schaft/Bohrungsdurchmesser | .7087 in |

| [Z] Anzahl der Spannuten | 4 |

| Abmessungsstandard | DIN 376 |

| Gewindetoleranzklasse ISO | 6HX-I |

Werkstoffe

- Stahl

Uses and application

Gewindedrehen: Sacklochbohrung

Toleranzklasse: 6HX

DIN 376

Anschnitt Form C (2–3)

HSS-E-PM

Innere Kühlmittelzuführung: Axial: Gewindebohren

Herstellerspezifikationen: M

Spiralwinkel Gewindebohrer: 15°

Grades

KP6525

Beschichtetes HSS-E-PM. PVD – beschichtet mit einer warm- und verschleißfesten Beschichtung mit hohem Vanadiumgehalt. HSS-Substrat aus Kobaltmetallpulver beschichtet mit einer verschleißfesten TiCN-Basisschicht und einer reibungsarmen TiN-Deckschicht. Anwendung in Stahl, Gusseisen und Aluminiumguss mit Silizium.

Features and benefits

- KP6525 TiCN + TiN für das Gewindebohren in Stahl und Gusseisen.

Lösung erstellen, um Vorschübe und Geschwindigkeiten zu berechnen

Nachdem Sie eine Lösung erstellt haben, wählen Sie einfach das Symbol für Vorschübe und Geschwindigkeiten und unser System gibt Ihnen Empfehlungen. Sie können die Informationen anpassen, indem Sie Ihre Maschine und Spezifikationen hinzufügen oder Anpassungen mithilfe der Schieberegler vornehmen.

Toleranz

Toleranzen

| Schaft Toleranz | |

| D | Toleranz h6 + / - |

| 12 | +0, -0,011 |

| 20 | +0, -0,013 |

| 32 | +0, -0,016 |

DIN 371

| D1 | Steigung | D | L | L3* | L2 | L5 | S10 |

| M3 | 0,5 | 3,5 | 56 | 11 | 18 | 6 | 2,7 |

| M3,5 | 0,6 | 4 | 56 | 12 | 20 | 6 | 3 |

| M4 | 0,7 | 4,5 | 63 | 13 | 21 | 6 | 3,4 |

| M4,5 | 0,75 | 6 | 70 | 16 | 25 | 8 | 4,9 |

| M5 | 0,8 | 6 | 70 | 16 | 25 | 8 | 4,9 |

| M6 | 1 | 6 | 80 | 19 | 30 | 8 | 4,9 |

| M7 | 1 | 7 | 80 | 19 | 30 | 8 | 5,5 |

| M8 | 0,75 | 8 | 80 | 18 | 30 | 9 | 6,2 |

| M8 | 1,25 | 8 | 90 | 22 | 35 | 9 | 6,2 |

| M9 | 0,75 | 9 | 80 | 18 | 30 | 10 | 7 |

| M9 | 1,25 | 9 | 90 | 22 | 35 | 10 | 7 |

| M10 | 1 | 10 | 90 | 20 | 35 | 11 | 8 |

| M10 | 1,5 | 10 | 100 | 24 | 39 | 11 | 8 |

DIN 374

| Steigung | |||||||

| D1 | Minimum | Maximum | D | L | L3* | L5 | S10 |

| M8 | 0,2 | 0,75 | 6 | 80 | 18 | 8 | 4,9 |

| M8 | — | 1 | 6 | 90 | 22 | 8 | 4,9 |

| M9 | 0,2 | 0,75 | 7 | 80 | 18 | 8 | 5,5 |

| M9 | — | 1 | 7 | 90 | 22 | 8 | 5,5 |

| M10 | 0,2 | 1 | 7 | 90 | 20 | 8 | 5,5 |

| M10 | — | 1,25 | 7 | 100 | 24 | 8 | 5,5 |

| M11 | 0,35 | 1 | 8 | 90 | 20 | 9 | 6,2 |

| M12 | 0,35 | 1,5 | 9 | 100 | 22 | 10 | 7 |

| M14 | 0,35 | 1,5 | 11 | 100 | 22 | 12 | 9 |

| M16 | 0,35 | 1,5 | 12 | 100 | 22 | 12 | 9 |

| M16 | — | 2 | 12 | 110 | 32 | 12 | 9 |

| M18 | 0,35 | 1,5 | 14 | 110 | 25 | 14 | 11 |

| M18 | — | 2 | 14 | 125 | 34 | 14 | 11 |

| M20 | 0,35 | 1,5 | 16 | 125 | 25 | 15 | 12 |

| M20 | — | 2 | 16 | 140 | 34 | 15 | 12 |

| M22 | 0,35 | 1,5 | 18 | 125 | 25 | 17 | 14,5 |

| M22 | — | 2 | 18 | 140 | 34 | 17 | 14,5 |

| M24 | 0,35 | 2 | 18 | 140 | 28 | 17 | 14,5 |

| M27 | 0,35 | 2 | 20 | 140 | 28 | 19 | 16 |

| M30 | 0,35 | 2 | 22 | 150 | 28 | 21 | 18 |

| M30 | — | 3 | 22 | 180 | 45 | 21 | 18 |

DIN 376

| D1 | Steigung | D | L | L3* | L5 | S10 |

| M8 | 1,25 | 6 | 90 | 22 | 8 | 4,9 |

| M9 | 1,25 | 7 | 90 | 22 | 8 | 5,5 |

| M10 | 1,5 | 7 | 100 | 24 | 8 | 5,5 |

| M11 | 1,5 | 8 | 100 | 24 | 9 | 6,2 |

| M12 | 1,75 | 9 | 110 | 28 | 10 | 7 |

| M14 | 2 | 11 | 110 | 30 | 12 | 9 |

| M16 | 2 | 12 | 110 | 32 | 12 | 9 |

| M18 | 2,5 | 14 | 125 | 34 | 14 | 11 |

| M20 | 2,5 | 16 | 140 | 34 | 15 | 12 |

| M22 | 2,5 | 18 | 140 | 34 | 17 | 14,5 |

| M24 | 3 | 18 | 160 | 38 | 17 | 14,5 |

| M27 | 3 | 20 | 160 | 38 | 19 | 16 |

| M30 | 3,5 | 22 | 180 | 45 | 21 | 18 |

| M33 | 3,5 | 25 | 180 | 50 | 23 | 20 |

| M36 | 4 | 28 | 200 | 56 | 25 | 22 |

| M39 | 4 | 32 | 200 | 60 | 27 | 24 |

| M42 | 4,5 | 32 | 200 | 60 | 27 | 24 |

| M45 | 4,5 | 36 | 220 | 65 | 32 | 29 |

JIS, Typ 3, metrisch, Normalgewinde

| D1 | Steigung | D | L | L3 | L5 | S10 |

| M8 | 1,25 | 6,2 | 70 | 22 | 8 | 5 |

| M9 | 1,25 | 7 | 72 | 22 | 8 | 5,5 |

| M10 | 1,5 | 7 | 75 | 24 | 8 | 5,5 |

| M11 | 1,5 | 8 | 80 | 25 | 9 | 6 |

| M12 | 1,75 | 8,5 | 82 | 29 | 9 | 6,5 |

| M14 | 2 | 10,5 | 88 | 30 | 11 | 8 |

| M16 | 2 | 12,5 | 95 | 32 | 13 | 10 |

| M18 | 2,5 | 14 | 100 | 37 | 14 | 11 |

| M20 | 2,5 | 15 | 105 | 37 | 15 | 12 |

| M22 | 2,5 | 17 | 115 | 38 | 16 | 13 |

| M24 | 3 | 19 | 120 | 45 | 18 | 15 |

Anwendungsdaten

| HSS-E-PM Taps • Grades KP6505 KP6525 KM6515 | ||||||||||||||||

| Tapping Operation | Ausführung des Gewindebohrers | Grade1 | Schnittgeschwindigkeit | |||||||||||||

| Startwert | ||||||||||||||||

| m/min | 3 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | |||

| SFM | 10 | 16 | 33 | 49 | 66 | 82 | 98 | 115 | 131 | 148 | 164 | 180 | 197 | |||

| P1 • Low-Carbon Steels, Long Chipping • Content: C 0.25% • Tensile Strength RM (MPa*): 530 • Hardness (HB) or HRC: 125 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 38 | 30 | 45 | |||||||||||

| 125 | 98 | 148 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 23 | 18 | 27 | |||||||||||

| 75 | 59 | 89 | ||||||||||||||

| P2 • Low-Carbon Steels, Free Machining, and Short Chipping • Content C 0.25% • Tensile Strength RM (MPa*): 650 • Hardness (HB) or HRC: 220 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 33 | 25 | 40 | |||||||||||

| 108 | 82 | 131 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 20 | 15 | 25 | |||||||||||

| 65 | 49 | 82 | ||||||||||||||

| P3 • Medium- and High-Plain Carbon Steels, Low-Alloyed • Content C | ||||||||||||||||

| Through Holes | T620 | KP6525 | 28 | 20 | 35 | |||||||||||

| 92 | 66 | 115 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 17 | 12 | 21 | |||||||||||

| 55 | 59 | 69 | ||||||||||||||

| P5 • Ferritic, Martensitic, and PH Stainless Steels • Content C= 0-0.4% • Tensile Strength RM (MPa*): 600–850 • Hardness (HB) HRC: 330 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 18 | 10 | 25 | |||||||||||

| 59 | 33 | 82 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 11 | 6 | 15 | |||||||||||

| 35 | 20 | 49 | ||||||||||||||

| P6 • High-Strength Ferritic, Martensitic, and PH Stainless Steels • Content C=0.1-0.6% • Tensile Strength RM (MPa*): 900-1350 • Hardness (HB) HRC: 350–450 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 10 | 5 | 15 | |||||||||||

| 33 | 16 | 49 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 6 | 3 | 9 | |||||||||||

| 20 | 10 | 30 | ||||||||||||||

| M1 • Austenitic Stainless Steel • Content C=0.05-0.15% • Tensile Strength RM (MPa*): 650 • Hardness (HB) or HRC: 130-200 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| M2 • High-Strength Austenitic Stainless and Cast Stainless Steels • Content C=0.05-0.15% • Tensile Strength RM (MPa*): 500 - 700 • Hardness (HB) or HRC: 150-230 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| M3 • Duplex Steel • Content C=0.05-0.2 % • Tensile Strength RM (MPa*): 900 • Hardness (HB) HRC: 135-275 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| K1 • Cast and Low-Strength Ductile Irons • Tensile Strength RM (MPa*): 150-400 • Hardness (HB) or HRC: 120-290 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 45 | 30 | 60 | |||||||||||

| 148 | 98 | 197 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 27 | 18 | 36 | |||||||||||

| 90 | 59 | 118 | ||||||||||||||

| K2 • Low- and Medium-Strength CGI and Ductile Irons • Tensile Strength RM (MPa*): 400-600 • Hardness (HB) or HRC: 130-260 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 38 | 25 | 50 | |||||||||||

| 125 | 82 | 164 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 23 | 15 | 30 | |||||||||||

| 75 | 49 | 98 | ||||||||||||||

| K3 • High-Strength Ductile and Austempered Ductile Iron • Tensile Strength RM (MPa*): 600-900 • Hardness (HB) or HRC: 180-350 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 30 | 20 | 40 | |||||||||||

| 98 | 66 | 131 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 18 | 12 | 25 | |||||||||||

| 59 | 39 | 82 | ||||||||||||||

| HSS-E-PM Taps • Grades KP6505 KP6525 KM6515 | ||||||||||||||||

| Tapping Operation | Ausführung des Gewindebohrers | Sorte | Schnittgeschwindigkeit | |||||||||||||

| Startwert | ||||||||||||||||

| m/min | 3 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | |||

| SFM | 10 | 16 | 33 | 49 | 66 | 82 | 98 | 115 | 131 | 148 | 164 | 180 | 197 | |||

| P1 • Low-Carbon Steels, Long Chipping • Content: C 0.25% • Tensile Strength RM (MPa*): 530 • Hardness (HB) or HRC: 125 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 38 | 30 | 45 | |||||||||||

| 125 | 98 | 148 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 23 | 18 | 27 | |||||||||||

| 75 | 59 | 89 | ||||||||||||||

| P2 • Low-Carbon Steels, Free Machining, and Short Chipping • Content C 0.25% • Tensile Strength RM (MPa*): 650 • Hardness (HB) or HRC: 220 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 33 | 25 | 40 | |||||||||||

| 108 | 82 | 131 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 20 | 15 | 25 | |||||||||||

| 65 | 49 | 82 | ||||||||||||||

| P3 • Medium- and High-Plain Carbon Steels, Low-Alloyed • Content C | ||||||||||||||||

| Through Holes | T620 | KP6525 | 28 | 20 | 35 | |||||||||||

| 92 | 66 | 115 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 17 | 12 | 21 | |||||||||||

| 55 | 59 | 69 | ||||||||||||||

| P5 • Ferritic, Martensitic, and PH Stainless Steels • Content C= 0-0.4% • Tensile Strength RM (MPa*): 600–850 • Hardness (HB) HRC: 330 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 18 | 10 | 25 | |||||||||||

| 59 | 33 | 82 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 11 | 6 | 15 | |||||||||||

| 35 | 20 | 49 | ||||||||||||||

| P6 • High-Strength Ferritic, Martensitic, and PH Stainless Steels • Content C=0.1-0.6% • Tensile Strength RM (MPa*): 900-1350 • Hardness (HB) HRC: 350–450 | ||||||||||||||||

| Through Holes | T620 | KP6525 | 10 | 5 | 15 | |||||||||||

| 33 | 16 | 49 | ||||||||||||||

| Blind Holes | T630 | KP6525 | 6 | 3 | 9 | |||||||||||

| 20 | 10 | 30 | ||||||||||||||

| M1 • Austenitic Stainless Steel • Content C=0.05-0.15% • Tensile Strength RM (MPa*): 650 • Hardness (HB) or HRC: 130-200 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| M2 • High-Strength Austenitic Stainless and Cast Stainless Steels • Content C=0.05-0.15% • Tensile Strength RM (MPa*): 500 - 700 • Hardness (HB) or HRC: 150-230 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| M3 • Duplex Steel • Content C=0.05-0.2 % • Tensile Strength RM (MPa*): 900 • Hardness (HB) HRC: 135-275 | ||||||||||||||||

| Through Holes | T620 | KM6515 | 15 | 10 | 20 | |||||||||||

| 49 | 33 | 66 | ||||||||||||||

| Blind Holes | T630 | KM6515 | 9 | 6 | 12 | |||||||||||

| 30 | 20 | 39 | ||||||||||||||

| K1 • Cast and Low-Strength Ductile Irons • Tensile Strength RM (MPa*): 150-400 • Hardness (HB) or HRC: 120-290 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 45 | 30 | 60 | |||||||||||

| 148 | 98 | 197 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 27 | 18 | 36 | |||||||||||

| 90 | 59 | 118 | ||||||||||||||

| K2 • Low- and Medium-Strength CGI and Ductile Irons • Tensile Strength RM (MPa*): 400-600 • Hardness (HB) or HRC: 130-260 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 38 | 25 | 50 | |||||||||||

| 125 | 82 | 164 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 23 | 15 | 30 | |||||||||||

| 75 | 49 | 98 | ||||||||||||||

| K3 • High-Strength Ductile and Austempered Ductile Iron • Tensile Strength RM (MPa*): 600-900 • Hardness (HB) or HRC: 180-350 | ||||||||||||||||

| Through Holes | T640 | KP6525 | 30 | 20 | 40 | |||||||||||

| 98 | 66 | 131 | ||||||||||||||

| Blind Holes | T640 | KP6525 | 18 | 12 | 25 | |||||||||||

| 59 | 39 | 82 | ||||||||||||||

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use