Boring Bar Deflection:

Calculating boring bar deflection, provides a means for analyzing a boring bar’s performance characteristics, prior to machining a part. Deflection can affect the surface finish or in extreme circumstances the part’s dimensional tolerances. To minimize deflection select a boring bar that offers the most rigidity with the shortest overhang.

Boring Bar Deflection (y) Formula:

y = FL33EI

F = Cutting force [lbf or N]

Cutting force = unit of power constant x d x f x Kp x C

unit of power constant = 396,000 (Imperial) or 60,000 (Metric)

d = DOC [inch or mm]

f = feed rate [inch per minute or mm per minute]

Kp = power constant [hp/inch3/minute or kW/mm3/minute]

C = feed rate factor for the power constant adjustment

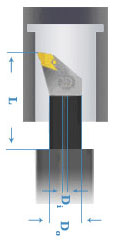

L = Unsupported length (overhang) of the boring bar [inch or mm]

E = Modulus of elasticity (in tension) for the boring bar material [psi or N/mm²]

Steel Modulus of elasticity = 30,000,000 psi

Steel Modulus of elasticity = 206,843 N/mm2

Heavy Metal (Tungsten alloy) modulus of elasticity = 48,000,000 psi

Heavy Metal (Tungsten alloy) modulus of elasticity = 330,948 N/mm2

Carbide Modulus of elasticity = 80,000,000 psi

Carbide Modulus of elasticity = 551,581 N/mm2

Note: The stated values are specific to Kennametal boring bars.

I = Moment of inertia for the boring bar cross-sectional area

Moment of Inertia for a solid cylindrical bar = π × DOD4 ÷ 64

Moment of Inertia for a hollow cylindrical bar = π × (DOD4 - DID4) ÷ 64

To use the boring bar deflection formula you must calculate the required cutting force (F), measure the boring bar’s overhang (L), select the correct modulus of elasticity for the boring bar (E), and calculate the moment of inertia for the boring bar’s cross-sectional area (I). Once those items are input into the formula the resulting outcome will be the amount of deflection (given as a distance).

If the resulting deflection is unacceptable; recalculate using a boring bar with a greater modulus of elasticity or a boring bar with a larger moment of inertia.

Deflection should be minimized but balanced against what is possible, based on the intended boring operation (depth and width).