High performance parts start with high performance materials

Kennametal is a global leader in the development and production of gas-atomized cobalt, nickel and iron-based alloy powders optimized for additive manufacturing. Our metal additive powders are field proven in a variety of additive processes, including powder bed fusion, direct energy deposition, and binder jet technology (BJT).

Metal additive manufacturing processes (metal 3D printing) represent the next generation in design freedom, manufacturing cost reduction, and supply chain optimization. These proven processes are being leveraged across a variety of industries and applications to develop and deploy high-performing parts both quickly and efficiently.

We offer our metal additive powders direct to customers for use in aerospace, oil and gas, automotive, energy, and medical 3D printing applications—or in combination with our end-to-end AM capabilities to produce fully-finished components and tooling.

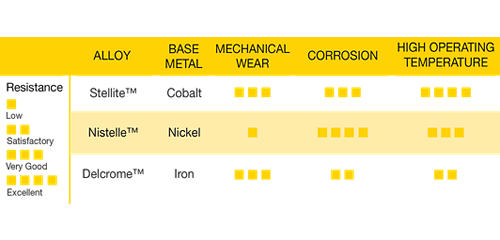

AM Metal Powder Portfolio

Kennametal Stellite™ powders can be tailored to meet your particle size distribution requirements. With superior process control, we achieve exceptional powder flowability and sphericity.