Bienvenue

Veuillez confirmer vos préférences

Mettre à jour les préférences

Suggestions de produit

Product Family suggestions

Nouveau client

Êtes-vous un nouveau client de Kennametal ? Créez un compte et commencez.

Créer un compteBonjour, User Name

Votre compte sélectionné :

Il y a un problème avec votre compte. Veuillez contacter le service client.

Compte Client Modifier le compte

Compte de livraison Modifier le compte

- Tableau de bord

- Gérer les commandes

- Gérer les canaux

- Carnet d’adresses

Notifications

Mark all as read- Modifier le mot de passe

- Mon profil

- Se déconnecter

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Usinez plus pour moins cher avec nos promotions! Achetez maintenant

Article(s) ajoutées avec succès au panier

Voir le panier

Voir le panier

Édition de la Solution

Ajout de Solution

Nom de la Solution:{{SolutionName}}Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

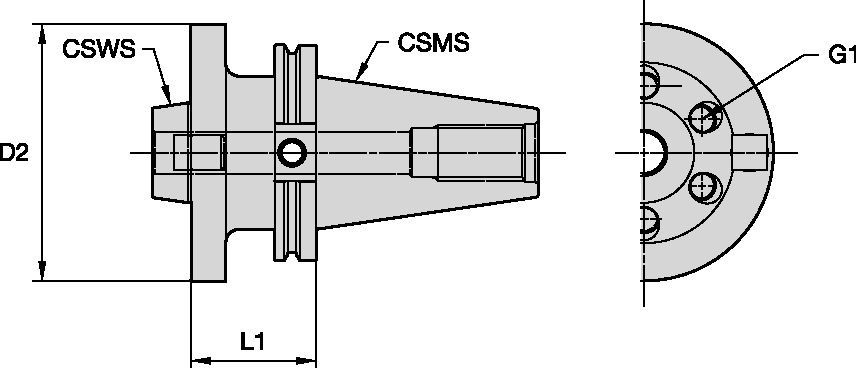

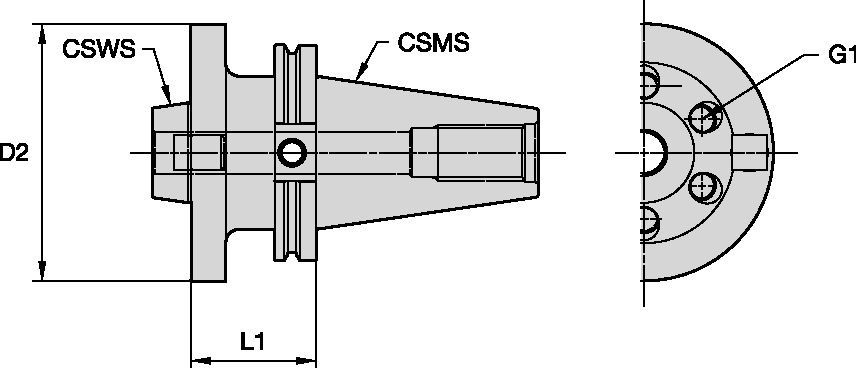

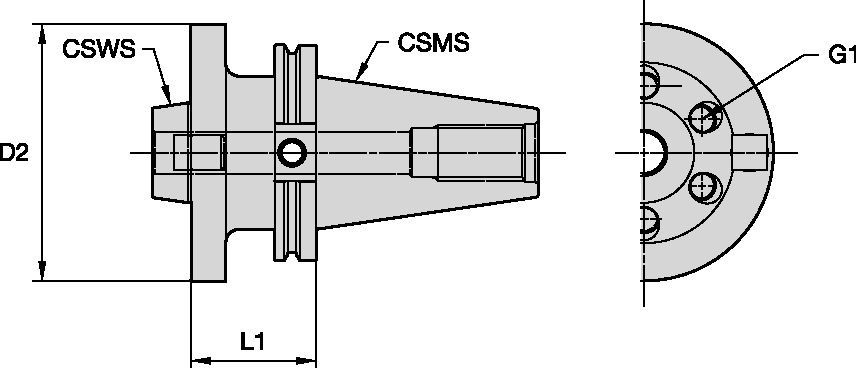

Fixation conique • CVF

Fixation conique • CVF

Features and benefits

- Designed for demanding applications like high-temperature alloy airframe structural parts machining.

- Higher stability than any straight flange connection, adding unequaled bending moment resistance.

- Large volume coolant supply through the center to support chip evacuation and to control heat in the cutting zone.

- Specially designed drive keys for maximum torque transmission.

- Six bolts for secure mounting.

- Taper pilot ensures maximum tool stabilization.

- Not interchangeable with CVKV-Taper Face Tooling.

Uses and application

Shank: Flange Mount

Équilibrage — G 6,3@ 15 000 t/mn

Arrosage interne : Entrée d'arrosage AD

48909

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| (Light geometry) | (Strong geometry) | |||||

| wear |  | toughness | ||||

| Geometry | Grade | Geometry | Grade | Geometry | Grade | |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| M1–M2 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| M3 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| S3 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| S4 | .S..GDH | KCSM40 | .S..GDH | KCSM40 | .S..GDH | KCSM40 |

| H1 | – | – | – | – | – | – |

Recommended Starting Feeds [IPT]

| Light | General | Heavy |

| Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | |||||||||||||||||

| Material | Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| P5 | .S..GDH | – | – | – | .007 | .012 | .018 | .006 | .010 | .016 | .005 | .008 | .013 | .003 | .005 | .007 | .S..GDH |

| P6 | .S..GDH | – | – | – | .007 | .010 | .015 | .006 | .009 | .013 | .005 | .007 | .011 | .003 | .004 | .006 | .S..GDH |

| M1 | .S..GDH | – | – | – | .007 | .011 | .017 | .006 | .010 | .015 | .005 | .008 | .012 | .003 | .004 | .007 | .S..GDH |

| M2 | .S..GDH | – | – | – | .007 | .011 | .017 | .006 | .010 | .015 | .005 | .008 | .012 | .003 | .004 | .007 | .S..GDH |

| M3 | .S..GDH | – | – | – | .007 | .010 | .015 | .006 | .009 | .013 | .005 | .007 | .011 | .003 | .004 | .006 | .S..GDH |

| S1 | .S..GDH | – | – | – | .007 | .008 | .012 | .006 | .007 | .011 | .005 | .006 | .009 | .003 | .003 | .005 | .S..GDH |

| S2 | .S..GDH | – | – | – | .007 | .008 | .012 | .006 | .007 | .011 | .005 | .006 | .009 | .003 | .003 | .005 | .S..GDH |

| S3 | .S..GDH | – | – | – | .007 | .009 | .014 | .006 | .008 | .012 | .005 | .007 | .010 | .003 | .004 | .006 | .S..GDH |

| S4 | .S..GDH | – | – | – | .007 | .011 | .017 | .006 | .010 | .015 | .005 | .008 | .012 | .003 | .004 | .007 | .S..GDH |

Recommended Starting Feeds [IPT]

| HARVI™ Ultra 8X • Recommended Starting Feeds [IPT] | ||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | |||||||||||

| 10% | 20% | 30% | 40–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| HARVI Ultra 8X - SNHJ....E..LEH | 0.004 | 0.007 | 0.008 | 0.003 | 0.005 | 0.006 | 0.002 | 0.004 | 0.005 | 0.002 | 0.004 | 0.005 |

| HARVI Ultra 8X - SNHJ....S..GDH | 0.005 | 0.008 | 0.010 | 0.004 | 0.006 | 0.008 | 0.003 | 0.005 | 0.007 | 0.003 | 0.005 | 0.006 |

| KSSM8+ - SNPJ…..S..GD | 0.007 | 0.015 | 0.023 | 0.005 | 0.011 | 0.017 | 0.004 | 0.009 | 0.015 | 0.004 | 0.009 | 0.014 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | ||||||||||||

Avances de départ recommandées [mm]

| Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | |||||||||||||||||

| Material | Insert Geometry | 5% | 10% | 20% | 30% | 40–100% | Insert Geometry | ||||||||||

| P5 | .S..GDH | – | – | – | 0,18 | 0,29 | 0,45 | 0,16 | 0,26 | 0,40 | 0,13 | 0,21 | 0,33 | 0,07 | 0,12 | 0,18 | .S..GDH |

| P6 | .S..GDH | – | – | – | 0,18 | 0,24 | 0,38 | 0,16 | 0,22 | 0,34 | 0,13 | 0,18 | 0,27 | 0,07 | 0,10 | 0,15 | .S..GDH |

| M1 | .S..GDH | – | – | – | 0,18 | 0,28 | 0,43 | 0,16 | 0,25 | 0,38 | 0,13 | 0,20 | 0,31 | 0,07 | 0,11 | 0,17 | .S..GDH |

| M2 | .S..GDH | – | – | – | 0,18 | 0,28 | 0,43 | 0,16 | 0,25 | 0,38 | 0,13 | 0,20 | 0,31 | 0,07 | 0,11 | 0,17 | .S..GDH |

| M3 | .S..GDH | – | – | – | 0,18 | 0,24 | 0,38 | 0,16 | 0,22 | 0,34 | 0,13 | 0,18 | 0,27 | 0,07 | 0,10 | 0,15 | .S..GDH |

| S1 | .S..GDH | – | – | – | 0,18 | 0,20 | 0,30 | 0,16 | 0,17 | 0,27 | 0,13 | 0,14 | 0,22 | 0,07 | 0,08 | 0,12 | .S..GDH |

| S2 | .S..GDH | – | – | – | 0,18 | 0,20 | 0,30 | 0,16 | 0,17 | 0,27 | 0,13 | 0,14 | 0,22 | 0,07 | 0,08 | 0,12 | .S..GDH |

| S3 | .S..GDH | – | – | – | 0,18 | 0,23 | 0,35 | 0,16 | 0,20 | 0,31 | 0,13 | 0,17 | 0,26 | 0,07 | 0,09 | 0,14 | .S..GDH |

| S4 | .S..GDH | – | – | – | 0,18 | 0,28 | 0,43 | 0,16 | 0,25 | 0,38 | 0,13 | 0,20 | 0,31 | 0,07 | 0,11 | 0,17 | .S..GDH |

| Light | General | Heavy |

Avances de départ recommandées [mm]

| HARVI™ Ultra 8X • Recommended Starting Feeds [mm/th] | ||||||||||||

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | |||||||||||

| 10% | 20% | 30% | 40–100% | |||||||||

| L | M | H | L | M | H | L | M | H | L | M | H | |

| HARVI Ultra 8X - SNHJ....E..LEH | 0.09 | 0.17 | 0.23 | 0.07 | 0.13 | 0.18 | 0.06 | 0.11 | 0.15 | 0.06 | 0.10 | 0.14 |

| HARVI Ultra 8X - SNHJ....S..GDH | 0.13 | 0.20 | 0.31 | 0.10 | 0.15 | 0.23 | 0.09 | 0.13 | 0.20 | 0.08 | 0.12 | 0.18 |

| KSSM8+ - SNPJ…..S..GD | 0,17 | 0,37 | 0,59 | 0,13 | 0,27 | 0,44 | 0,11 | 0,24 | 0,38 | 0,10 | 0,22 | 0,35 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | ||||||||||||

Recommended Starting Speeds [SFM]

| Material Group | KC725M | KCSM40 | |||||

| P | 1 | ||||||

| 2 | |||||||

| 3 | |||||||

| 4 | |||||||

| 5 | 390 | 355 | 315 | 820 | 450 | 410 | |

| 6 | 340 | 265 | 210 | 740 | 415 | 375 | |

| M | 1 | 450 | 390 | 355 | 885 | 415 | 375 |

| 2 | 410 | 340 | 290 | 885 | 415 | 375 | |

| 3 | 300 | 265 | 210 | 655 | 290 | 260 | |

| K | 1 | ||||||

| 2 | |||||||

| 3 | |||||||

| N | 1 | ||||||

| 2 | |||||||

| 3 | |||||||

| S | 1 | 90 | 80 | 65 | 195 | 90 | 75 |

| 2 | 90 | 80 | 65 | 165 | 90 | 70 | |

| 3 | 120 | 90 | 65 | 180 | 105 | 80 | |

| 4 | 145 | 120 | 80 | 260 | 150 | 115 | |

| H | 1 | ||||||

| 2 | |||||||

| 3 | |||||||

| HARVI™ Ultra 8X • Recommended Starting Speed [SFM] | |||||||||||||||||||

| Kalite | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | KCSM40 | |||||||||||||

| Chip Thickness hex Inch | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | |||||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | 855 | 755 | 705 | – | – | – | 1495 | 1295 | 1215 | – | – | – | 970 | 855 | 805 | 1150 | 1050 | 985 |

| 2 | 720 | 625 | 525 | – | – | – | 920 | 835 | 755 | – | – | – | 820 | 705 | 590 | 985 | 885 | 720 | |

| 3 | 655 | 560 | 460 | – | – | – | 835 | 755 | 675 | – | – | – | 755 | 640 | 525 | 920 | 785 | 640 | |

| 4 | 590 | 490 | 395 | – | – | – | 740 | 605 | 525 | – | – | – | 675 | 560 | 445 | 785 | 675 | 540 | |

| 5 | 490 | 445 | 395 | – | – | – | 625 | 560 | 490 | – | – | – | 560 | 510 | 445 | 655 | 590 | 525 | |

| 6 | 425 | 330 | 260 | – | – | – | 525 | 445 | 360 | – | – | – | 490 | 375 | 295 | 590 | 460 | 330 | |

| M | 1 | 560 | 490 | 445 | – | – | – | 675 | 605 | 510 | – | – | – | 640 | 560 | 510 | 855 | 690 | 605 |

| 2 | 510 | 425 | 360 | – | – | – | 605 | 525 | 460 | – | – | – | 575 | 490 | 410 | 770 | 590 | 475 | |

| 3 | 375 | 330 | 260 | – | – | – | 475 | 425 | 375 | – | – | – | 425 | 375 | 295 | 575 | 475 | 360 | |

| K | 1 | – | – | – | 1380 | 1265 | 1115 | 970 | 870 | 785 | 1180 | 950 | 805 | – | – | – | – | – | – |

| 2 | – | – | – | 1100 | 970 | 900 | 770 | 690 | 625 | 920 | 755 | 640 | – | – | – | – | – | – | |

| 3 | – | – | – | 920 | 820 | 755 | 640 | 575 | 525 | 690 | 575 | 460 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 165 | 130 | 80 |

| 2 | 115 | 100 | 80 | – | – | – | – | – | – | – | – | – | 130 | 115 | 100 | 180 | 130 | 80 | |

| 3 | 150 | 115 | 80 | – | – | – | – | – | – | – | – | – | 165 | 130 | 100 | 215 | 150 | 100 | |

| 4 | 165 | 150 | 100 | – | – | – | 165 | 150 | 115 | – | – | – | 180 | 165 | 115 | 245 | 195 | 130 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||

Vitesses de départ recommandées [m/mn]

| Material Group | KC725M | KCSM40 | |||||

| P | 1 | ||||||

| 2 | |||||||

| 3 | |||||||

| 4 | |||||||

| 5 | 120 | 110 | 95 | 250 | 138 | 125 | |

| 6 | 105 | 80 | 65 | 225 | 127 | 115 | |

| M | 1 | 135 | 120 | 110 | 270 | 127 | 115 |

| 2 | 125 | 105 | 90 | 270 | 127 | 115 | |

| 3 | 90 | 80 | 65 | 200 | 88 | 80 | |

| K | 1 | ||||||

| 2 | |||||||

| 3 | |||||||

| N | 1 | ||||||

| 2 | |||||||

| 3 | |||||||

| S | 1 | 30 | 25 | 20 | 60 | 25 | 23 |

| 2 | 30 | 25 | 20 | 50 | 23 | 21 | |

| 3 | 35 | 30 | 20 | 55 | 26 | 24 | |

| 4 | 45 | 35 | 25 | 80 | 39 | 35 | |

| H | 1 | ||||||

| 2 | |||||||

| 3 | |||||||

Vitesses de départ recommandées [m/mn]

| HARVI™ Ultra 8X • Recommended Starting Speed [m/min] | |||||||||||||||||||

| Kalite | KC725M | KCK15 | KCPK30 | KCK20B | KCPM40 | KCSM40 | |||||||||||||

| Talaş kalınlığı hex mm | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | Min. | Maks. | |||||||

| Malzeme grubu | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | Maks. | Başlangıç | Min. | |

| P | 1 | 260 | 230 | 215 | – | – | – | 455 | 395 | 370 | – | – | – | 295 | 260 | 245 | 350 | 320 | 300 |

| 2 | 220 | 190 | 160 | – | – | – | 280 | 255 | 230 | – | – | – | 250 | 215 | 180 | 300 | 270 | 220 | |

| 3 | 200 | 170 | 140 | – | – | – | 255 | 230 | 205 | – | – | – | 230 | 195 | 160 | 280 | 240 | 195 | |

| 4 | 180 | 150 | 120 | – | – | – | 225 | 185 | 160 | – | – | – | 205 | 170 | 135 | 240 | 205 | 165 | |

| 5 | 150 | 135 | 120 | – | – | – | 190 | 170 | 150 | – | – | – | 170 | 155 | 135 | 200 | 180 | 160 | |

| 6 | 130 | 100 | 80 | – | – | – | 160 | 135 | 110 | – | – | – | 150 | 115 | 90 | 180 | 140 | 100 | |

| M | 1 | 170 | 150 | 135 | – | – | – | 205 | 185 | 155 | – | – | – | 195 | 170 | 155 | 260 | 210 | 185 |

| 2 | 155 | 130 | 110 | – | – | – | 185 | 160 | 140 | – | – | – | 175 | 150 | 125 | 235 | 180 | 145 | |

| 3 | 115 | 100 | 80 | – | – | – | 145 | 130 | 115 | – | – | – | 130 | 115 | 90 | 175 | 145 | 110 | |

| K | 1 | – | – | – | 420 | 385 | 340 | 295 | 265 | 240 | 360 | 290 | 245 | – | – | – | – | – | – |

| 2 | – | – | – | 335 | 295 | 275 | 235 | 210 | 190 | 280 | 230 | 195 | – | – | – | – | – | – | |

| 3 | – | – | – | 280 | 250 | 230 | 195 | 175 | 160 | 210 | 175 | 140 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 50 | 40 | 25 |

| 2 | 35 | 30 | 25 | – | – | – | – | – | – | – | – | – | 40 | 35 | 30 | 55 | 40 | 25 | |

| 3 | 45 | 35 | 25 | – | – | – | – | – | – | – | – | – | 50 | 40 | 30 | 65 | 45 | 30 | |

| 4 | 50 | 45 | 30 | – | – | – | 50 | 45 | 35 | – | – | – | 55 | 50 | 35 | 75 | 60 | 40 | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| maks. orta boy min. | |||||||||||||||||||