Produit similaire à:

Plaquettes pour KSOM • OFPT-HB

Plaquettes indexables

Numéro de matériel2035688

Ref. ISO CatalogueOFPT07L6AFSNHBRef. ANSI CatalogueOFPT64AFSN6HB

- P Acier

- M Acier inoxydable

- S Alliages hautes températures

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

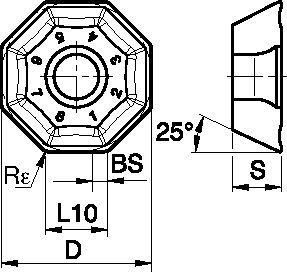

| Numéro de matériel | 2035688 |

| Ref. ISO Catalogue | OFPT07L6AFSNHB |

| Ref. ANSI Catalogue | OFPT64AFSN6HB |

| Nuance | KC725M |

| [D] Taille de plaquette CI | 18.7 mm |

| [D] Taille de plaquette CI | .736 in |

| [S] Épaisseur de la plaquette | 6 mm |

| [S] Épaisseur de la plaquette | .2362 in |

| [L10] Longueur d’arête de coupe de la plaquette | 7.5 mm |

| [L10] Longueur d’arête de coupe de la plaquette | .295 in |

| [Rε] Rayon de bec | 1.2 mm |

| [Rε] Rayon de bec | .0472 in |

| Épaisseur moyenne du copeau [HM] | 0.21 mm |

| Épaisseur moyenne du copeau [HM] | .0083 in |

| Arêtes de coupe par plaquette | 8 |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Alliages hautes températures

Features and benefits

- Premier choix pour les travaux lourds.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Guide de sélection des plaquettes

| Malzeme grubu | Hafif işleme | Genel amaçlı kullanım | Ağır işleme | |||

| (Hafif geometri) | – | (Sert geometri) | ||||

| Aşınma direnci |  | Tokluk | ||||

| Geometri | Kalite | Geometri | Kalite | Geometri | Kalite | |

| P1–P2 | .E..LB | KCPK30 | .E..GB | KCPM40 | .S..HB | KCPM40 |

| P3–P4 | .E..LB | KCPK30 | .E..GB | KCPK30 | .S..HB | KCPK30 |

| P5–P6 | .E..LB | KC725M | .E..GB | KC725M | .S..HB | KC725M |

| M1–M2 | .E..LB | KC725M | .E..GB | KC725M | .S..HB | KC725M |

| M3 | .E..LB | KCSM40 | .E..GB | KCSM40 | .S..HB | KCSM40 |

| K1–K2 | .E..LB | KCK15 | .E..GB | KC520M | .S..HB | KCK15 |

| K3 | .E..LB | KC520M | .E..GB | KC520M | .S..HB | KC520M |

| N1–N2 | .F..LNJ | KC410M | .F..LNJ | KC410M | .F..LNJ | KC410M |

| N3 | .F..LNJ | KC410M | .F..LNJ | KC410M | .F..LNJ | KC410M |

| S1–S2 | .E..LB | KC725M | .E..GB | KC725M | .S..HB | KC725M |

| S3 | .E..LB | KCSM40 | .E..GB | KCSM40 | .S..HB | KCSM40 |

| S4 | .E..LB | KCSM40 | .E..GB | KCSM40 | .S..HB | KCSM40 |

| H1 | – | – | – | – | – | – |

Feeds

Avances de départ recommandées [mm]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LNJ | 0,17 | 0,67 | 1,20 | 0,12 | 0,49 | 0,86 | 0,09 | 0,36 | 0,64 | 0,08 | 0,32 | 0,56 | 0,07 | 0,29 | 0,51 | .F..LNJ |

| .E..LB | 0,34 | 0,75 | 1,20 | 0,25 | 0,54 | 0,86 | 0,19 | 0,40 | 0,64 | 0,16 | 0,35 | 0,56 | 0,15 | 0,32 | 0,51 | .E..LB |

| .S..LB | 0,34 | 0,73 | 1,33 | 0,25 | 0,53 | 0,96 | 0,19 | 0,39 | 0,71 | 0,16 | 0,34 | 0,62 | 0,15 | 0,32 | 0,57 | .S..LB |

| .E..GB | 0,34 | 0,87 | 1,40 | 0,25 | 0,62 | 1,00 | 0,19 | 0,47 | 0,74 | 0,16 | 0,41 | 0,65 | 0,15 | 0,37 | 0,59 | .E..GB |

| .S..HB | 0,34 | 0,87 | 1,49 | 0,25 | 0,62 | 1,07 | 0,19 | 0,47 | 0,79 | 0,16 | 0,41 | 0,69 | 0,15 | 0,37 | 0,63 | .S..HB |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

Recommended Starting Feeds [IPT]

| Kesici uç geometrisi | Frezenin iş parçasına radyal giriş temasında (ae), diş başına başlangıç ilerleme (Fz) % oranı. | Kesici uç geometrisi | ||||||||||||||

| 5% | 10% | 20% | 30% | 40–100% | ||||||||||||

| .F..LNJ | .007 | .027 | .048 | .005 | .019 | .035 | .004 | .015 | .026 | .003 | .013 | .022 | .003 | .012 | .021 | .F..LNJ |

| .E..LB | .014 | .029 | .047 | .010 | .021 | .034 | .007 | .016 | .025 | .006 | .014 | .022 | .006 | .013 | .020 | .E..LB |

| .S..LB | .014 | .029 | .053 | .010 | .021 | .038 | .007 | .016 | .028 | .006 | .014 | .025 | .006 | .012 | .022 | .S..LB |

| .E..GB | .014 | .034 | .055 | .010 | .025 | .039 | .007 | .018 | .029 | .006 | .016 | .026 | .006 | .015 | .023 | .E..GB |

| .S..HB | .014 | .034 | .059 | .010 | .025 | .042 | .007 | .018 | .031 | .006 | .016 | .027 | .006 | .015 | .025 | .S..HB |

| Hafif işleme | Genel amaçlı kullanım | Ağır işleme |

Speeds

Vitesses de départ recommandées [m/mn]

| Malzeme grubu | KC410M | KC520M | KC522M | KC725M | KCK15 | KCPM20 | KCPK30 | |||||||||||||||

| P | 1 | – | – | – | – | – | – | 395 | 345 | 325 | 315 | 275 | 255 | – | – | – | 660 | 580 | 535 | 545 | 475 | 440 |

| 2 | – | – | – | – | – | – | 330 | 290 | 240 | 260 | 230 | 195 | – | – | – | 410 | 370 | 330 | 335 | 305 | 275 | |

| 3 | – | – | – | – | – | – | 305 | 255 | 215 | 240 | 205 | 170 | – | – | – | 370 | 330 | 305 | 305 | 275 | 250 | |

| 4 | – | – | – | – | – | – | 270 | 225 | 180 | 215 | 180 | 145 | – | – | – | 275 | 255 | 230 | 225 | 210 | 190 | |

| 5 | – | – | – | – | – | – | 225 | 200 | 180 | 180 | 160 | 145 | – | – | – | 330 | 300 | 275 | 310 | 275 | 255 | |

| 6 | – | – | – | – | – | – | 200 | 150 | 120 | 160 | 120 | 95 | – | – | – | 230 | 200 | 175 | 190 | 165 | – | |

| M | 1 | – | – | – | – | – | – | 245 | 215 | 200 | 205 | 180 | 165 | – | – | – | 270 | 240 | 205 | 250 | 220 | 190 |

| 2 | – | – | – | – | – | – | 225 | 190 | 160 | 185 | 160 | 130 | – | – | – | 245 | 215 | 190 | 225 | 195 | 170 | |

| 3 | – | – | – | – | – | – | 170 | 145 | 115 | 140 | 120 | 95 | – | – | – | 195 | 175 | 150 | 175 | 160 | 140 | |

| K | 1 | – | – | – | 325 | 295 | 260 | 275 | 250 | 220 | – | – | – | 505 | 460 | 410 | 435 | 390 | 350 | 355 | 320 | 285 |

| 2 | – | – | – | 255 | 225 | 215 | 215 | 195 | 180 | – | – | – | 400 | 355 | 330 | 345 | 310 | 280 | 280 | 255 | 230 | |

| 3 | – | – | – | 215 | 190 | 170 | 180 | 160 | 145 | – | – | – | 335 | 300 | 275 | 290 | 255 | 240 | 235 | 210 | 195 | |

| N | 1–2 | 1460 | 1300 | 1195 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 1300 | 1195 | 1100 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 50 | 45 | 35 | 45 | 35 | 30 | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 50 | 45 | 35 | 45 | 35 | 30 | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 60 | 50 | 35 | 55 | 45 | 30 | – | – | – | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 85 | 60 | 45 | 75 | 55 | 35 | – | – | – | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Recommended Starting Speeds [SFM]

| Malzeme grubu | KC410M | KC520M | KC522M | KC725M | KCK15 | KCPK30 | |||||||||||||

| P | 1 | – | – | – | – | – | – | 1300 | 1130 | 1060 | 1030 | 900 | 840 | – | – | – | 1780 | 1560 | 1450 |

| 2 | – | – | – | – | – | – | 1080 | 950 | 790 | 860 | 760 | 640 | – | – | – | 1100 | 1000 | 900 | |

| 3 | – | – | – | – | – | – | 1000 | 840 | 700 | 790 | 670 | 550 | – | – | – | 1000 | 900 | 820 | |

| 4 | – | – | – | – | – | – | 890 | 730 | 590 | 710 | 590 | 470 | – | – | – | 740 | 690 | 620 | |

| 5 | – | – | – | – | – | – | 730 | 660 | 590 | 590 | 530 | 470 | – | – | – | 1020 | 910 | 830 | |

| 6 | – | – | – | – | – | – | 650 | 490 | 400 | 520 | 400 | 310 | – | – | – | 620 | 540 | – | |

| M | 1 | – | – | – | – | – | – | 800 | 710 | 650 | 670 | 590 | 540 | – | – | – | 820 | 720 | 620 |

| 2 | – | – | – | – | – | – | 730 | 620 | 520 | 610 | 520 | 430 | – | – | – | 730 | 640 | 550 | |

| 3 | – | – | – | – | – | – | 550 | 480 | 370 | 460 | 400 | 310 | – | – | – | 570 | 520 | 460 | |

| K | 1 | – | – | – | 1060 | 960 | 850 | 900 | 820 | 720 | – | – | – | 1660 | 1510 | 1340 | 1160 | 1050 | 940 |

| 2 | – | – | – | 830 | 740 | 700 | 710 | 640 | 590 | – | – | – | 1310 | 1170 | 1090 | 920 | 830 | 760 | |

| 3 | – | – | – | 700 | 620 | 560 | 590 | 530 | 480 | – | – | – | 1100 | 980 | 900 | 770 | 690 | 640 | |

| N | 1–2 | 4790 | 4260 | 3920 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 3 | 4260 | 3920 | 3600 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | 160 | 140 | 110 | 140 | 120 | 100 | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | 200 | 160 | 110 | 180 | 140 | 100 | – | – | – | – | – | – | |

| 4 | – | – | – | – | – | – | 280 | 200 | 140 | 240 | 180 | 120 | – | – | – | – | – | – | |

| H | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

Données d'application

Plongée

| D1 mm | D1 maks mm | Ap maks | Rampalama açısı (°) | Rampalama uzunluğu mm |

| 63 | 74,2 | 9 | 5,5 | 121,5 |

| 80 | 91,1 | 9 | 4,0 | 167,3 |

| 100 | 111,0 | 9 | 3,0 | 223,2 |

| 125 | 135,9 | 9 | 2,3 | 291,3 |

| 160 | 170,8 | 9 | 1,7 | 394,2 |

Surfaçage

| max DOC Ap | mm | talaş yükleme (fz) |

| Ap1 maks. | 5,0 | 1 x fz |

| Ap2 maks | 11,0 | 0,6 x fz |

Ramping

| maksimum dalma derinliği | mm |

| Ap1 maks. | 4,2 |

Interpolation hélicoïdale

| D1 mm | D1 maks mm | Delik çapı | Ap/rev mm | |

| min mm | maks mm | |||

| 63 | 74,2 | 122,7 | 145,0 | 6,3 |

| 80 | 91,1 | 156,6 | 178,0 | 6,3 |

| 100 | 111,0 | 196,5 | 218,7 | 6,3 |

| 125 | 135,9 | 246,4 | 268,7 | 6,3 |

| 160 | 170,8 | 316,9 | 338,6 | 6,3 |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use