Produit similaire à:

KDMB • Ball Nose Finisher • End Mills • Inch

Indexable Ball Nose Finisher

Numéro de matériel2878448

Ref. ISO CatalogueKDMB0750R748A075STRef. ANSI CatalogueKDMB0750R748A075ST

- P Acier

- M Acier inoxydable

- K Fonte

- N Non ferreux

- S Alliages hautes températures

- H Matériaux trempés

Ramping : Ébauche

Rainurage : Bout hémisphérique

Fraisage de côté/avec épaulement : Bout hémisphérique

Profilage 3D

Queue — Cylindrique Classique

Usinage de poches

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Aperçu

- Données d'application

- Téléchargements

- Pièces compatibles côté machine

- Pièces compatibles côté pièce

- Pièces de rechange

- Révision

- FAQ

| Numéro de matériel | 2878448 |

| Ref. ISO Catalogue | KDMB0750R748A075ST |

| Ref. ANSI Catalogue | KDMB0750R748A075ST |

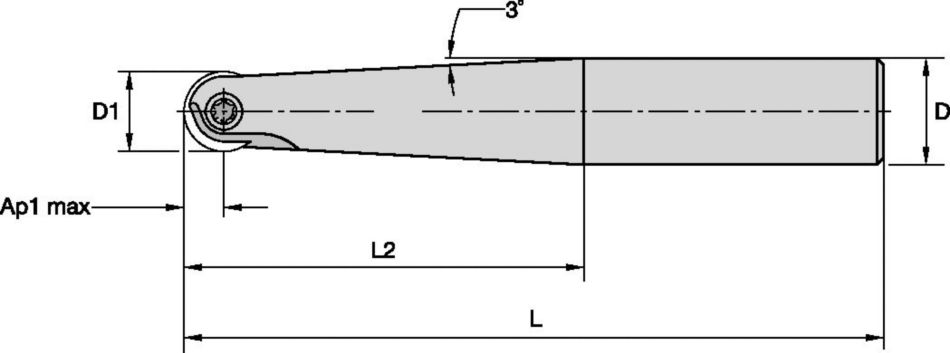

| [D1] Diamètre effectif de coupe | 19.05 mm |

| [D1] Diamètre effectif de coupe | 0.75 in |

| [D] Adaptateur / Queue / Diamètre d’alésage | 25.4 mm |

| [D] Adaptateur / Queue / Diamètre d’alésage | 1 in |

| [L] Longueur totale | 190 mm |

| [L] Longueur totale | 7.48 in |

| [L2] Longueur de tête | 80 mm |

| [L2] Longueur de tête | 3.15 in |

| [AP1MAX] 1re profondeur de coupe maximale | 9.525 mm |

| [AP1MAX] 1re profondeur de coupe maximale | 0.375 in |

| Nombre de plaquettes | 1 |

| [Z] Nombre de goujures | 2 |

| Angle de ramping maximum | 3 |

| T/Min max | 40000 |

| Plaquette étalon | KDMB0750. |

| Poids Livres | 1.41 |

Matériaux de pièce à usiner

- Acier

- Acier inoxydable

- Fonte

- Non ferreux

- Alliages hautes températures

- Matériaux trempés

Uses and application

Ramping : Ébauche

Rainurage : Bout hémisphérique

Fraisage de côté/avec épaulement : Bout hémisphérique

Profilage 3D

Queue — Cylindrique Classique

Usinage de poches

Features and benefits

- Available diameters: .312–1.250".

- Ball nose finishers for 3D milling applications.

- Suitable for roughing and finishing operations.

- Tapered version ideal for 5-axis applications.

- High precision and runout accuracy.

- Can be used with heat shrink technology, h6 shank tolerance.

Créez une Solution pour calculer les avances et vitesses

Après avoir créé une Solution, choisissez simplement l'icône "Avances et Vitesses" et notre système vous fournira ses recommandations. Vous pouvez les personnaliser en ajoutant votre machine et vos spécifications techniques, ou en ajustant votre demande à l'aide des curseurs.

Feeds

KDMB Ball Nose • .250"

| Diamètre de coupe (Dw) à profondeur de coupe axiale (ap) | ||||

| D1 maxi | 0.125 | 0.050 | 0.025 | 0.013 |

| 0.250 | 0.250 | 0.200 | 0.150 | 0.109 |

At .125 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .050 Axial Depth of Cut (ap)

| Travaux légers | Applications générales | Travaux lourds |

At .025 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

At .013 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..LD |

| .E..GP | .006 | .008 | .015 | .004 | .006 | .011 | .004 | .005 | .010 | .004 | .005 | .009 | .004 | .005 | .009 | .E..GP |

KDMB Ball Nose • .312"

| Diamètre de coupe (Dw) à profondeur de coupe axiale (ap) | ||||

| D1 maxi | 0.156 | 0.047 | 0.031 | 0.016 |

| 0.313 | 0.313 | 0.223 | 0.188 | 0.136 |

At .156 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .047 Axial Depth of Cut (ap)

| Travaux légers | Applications générales | Travaux lourds |

At .031 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

At .016 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

KDMB Ball Nose • .375"

| Diamètre de coupe (Dw) à profondeur de coupe axiale (ap) | ||||

| D1 maxi | 0.188 | 0.056 | 0.038 | 0.019 |

| 0.375 | 0.375 | 0.268 | 0.225 | 0.163 |

At .188 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .056 Axial Depth of Cut (ap)

| Travaux légers | Applications générales | Travaux lourds |

At .038 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

At .019 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

KDMB Ball Nose • .500"

| Diamètre de coupe (Dw) à profondeur de coupe axiale (ap) | ||||

| D1 maxi | 0.250 | 0.075 | 0.050 | 0.025 |

| 0.500 | 0.500 | 0.357 | 0.300 | 0.218 |

At .250 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .075 Axial Depth of Cut (ap)

| Travaux légers | Applications générales | Travaux lourds |

At .050 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

At .025 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • .625"

| Diamètre de coupe (Dw) à profondeur de coupe axiale (ap) | ||||

| D1 maxi | 0.313 | 0.094 | 0.063 | 0.031 |

| 0.625 | 0.625 | 0.446 | 0.375 | 0.272 |

At .313 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .094 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .063 Axial Depth of Cut (ap)

| Travaux légers | Applications générales | Travaux lourds |

At .031 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • .750"

| Diamètre de coupe (Dw) à profondeur de coupe axiale (ap) | ||||

| D1 maxi | 0.375 | 0.113 | 0.075 | 0.038 |

| 0.750 | 0.750 | 0.536 | 0.450 | 0.327 |

At .375 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .113 Axial Depth of Cut (ap)

| Travaux légers | Applications générales | Travaux lourds |

At .075 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .038 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • 1.00"

| Diamètre de coupe (Dw) à profondeur de coupe axiale (ap) | ||||

| D1 maxi | 0.500 | 0.150 | 0.100 | 0.050 |

| 1.000 | 1.000 | 0.714 | 0.600 | 0.436 |

At .500 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

| .E..GN | .007 | .010 | .018 | .005 | .008 | .013 | .004 | .007 | .011 | .004 | .006 | .011 | .004 | .006 | .011 | .E..GN |

| .E..HC | .007 | .014 | .024 | .005 | .010 | .018 | .004 | .009 | .015 | .004 | .008 | .014 | .004 | .008 | .014 | .E..HC |

At .150 Axial Depth of Cut (ap)

| Travaux légers | Applications générales | Travaux lourds |

At .100 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

| .E..GN | .009 | .014 | .025 | .007 | .011 | .019 | .006 | .009 | .016 | .006 | .009 | .015 | .006 | .008 | .015 | .E..GN |

| .E..HC | .009 | .019 | .034 | .007 | .014 | .025 | .006 | .012 | .021 | .006 | .011 | .020 | .006 | .011 | .020 | .E..HC |

At .050 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

| .E..GN | .016 | .024 | .042 | .012 | .017 | .031 | .010 | .015 | .026 | .009 | .014 | .025 | .009 | .014 | .024 | .E..GN |

| .E..HC | .016 | .032 | .057 | .012 | .023 | .041 | .010 | .020 | .035 | .009 | .019 | .033 | .009 | .018 | .032 | .E..HC |

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| .E..GN | .011 | .017 | .030 | .008 | .013 | .022 | .007 | .011 | .019 | .007 | .010 | .018 | .007 | .010 | .018 | .E..GN |

| .E..HC | .011 | .023 | .041 | .008 | .017 | .030 | .007 | .015 | .026 | .007 | .014 | .024 | .007 | .013 | .023 | .E..HC |

KDMB Ball Nose • 1.25"

| Diamètre de coupe (Dw) à profondeur de coupe axiale (ap) | ||||

| D1 maxi | 0.625 | 0.188 | 0.125 | 0.063 |

| 1.250 | 1.250 | 0.893 | 0.750 | 0.545 |

At .625 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..LD |

| .E..GP | .005 | .007 | .012 | .004 | .005 | .009 | .003 | .004 | .008 | .003 | .004 | .007 | .003 | .004 | .007 | .E..GP |

At .188 Axial Depth of Cut (ap)

| Travaux légers | Applications générales | Travaux lourds |

At .125 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..LD |

| .E..GP | .011 | .016 | .028 | .008 | .012 | .020 | .007 | .010 | .018 | .007 | .009 | .016 | .006 | .009 | .016 | .E..GP |

At .063 Axial Depth of Cut (ap)

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..LD |

| .E..GP | .008 | .011 | .020 | .006 | .008 | .015 | .005 | .007 | .013 | .005 | .007 | .012 | .005 | .007 | .012 | .E..GP |

| Géométrie de plaquette | Avance par dent de départ recommandée (Fz) en relation avec le % de l'Engagement Radial (ae) | Géométrie de plaquette | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..LD | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..LD |

| .E..GP | .007 | .009 | .017 | .005 | .007 | .012 | .004 | .006 | .011 | .004 | .006 | .010 | .004 | .006 | .010 | .E..GP |

Speeds

Recommended Starting Speeds [SFM]

| Groupe Matières | K115M | KC505M | KC515M | KC530M | |||||||||

| P | 1 | – | – | – | – | – | – | 1080 | 960 | 840 | 900 | 780 | 660 |

| 2 | – | – | – | – | – | – | 1020 | 900 | 780 | 780 | 660 | 540 | |

| 3 | – | – | – | – | – | – | 900 | 780 | 660 | 660 | 600 | 540 | |

| 4 | – | – | – | 1180 | 860 | 710 | 780 | 660 | 540 | 600 | 540 | 480 | |

| 5 | – | – | – | 1180 | 860 | 710 | 660 | 540 | 420 | 540 | 480 | 420 | |

| 6 | – | – | – | 1140 | 780 | 620 | 540 | 420 | 360 | 420 | 360 | 300 | |

| M | 1 | – | – | – | – | – | – | 1080 | 900 | 780 | 900 | 720 | 600 |

| 2 | – | – | – | – | – | – | 900 | 720 | 540 | 600 | 480 | 420 | |

| 3 | – | – | – | – | – | – | 720 | 600 | 480 | 480 | 420 | 360 | |

| K | 1 | 720 | 600 | 480 | – | – | – | 1440 | 1080 | 720 | – | – | – |

| 2 | 600 | 480 | 360 | – | – | – | 1080 | 840 | 600 | – | – | – | |

| 3 | 360 | 300 | 240 | – | – | – | 480 | 360 | 240 | – | – | – | |

| N | 1–2 | 1440 | 1080 | 720 | – | – | – | – | – | – | – | – | – |

| 3 | 960 | 720 | 600 | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | |

| 4 | 300 | 230 | 160 | – | – | – | – | – | – | 260 | 200 | 170 | |

| H | 1 | – | – | – | 860 | 670 | 550 | 550 | 400 | 310 | – | – | – |

KDMB Ball Nose Platform • .250"

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| – | (géomètrie légère) | – | (géomètrie solide) | |||

| – | résistance à l’usure |  | ténacité | |||

| – | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | – | – | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC515M | .E..GP | KC515M | – | – |

KDMB Ball Nose Platform • .312"

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| – | (géomètrie légère) | – | (géomètrie solide) | |||

| – | résistance à l’usure |  | ténacité | |||

| – | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .375"

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| – | (géomètrie légère) | – | (géomètrie solide) | |||

| – | résistance à l’usure |  | ténacité | |||

| – | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | – | – |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .500"

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| – | (géomètrie légère) | – | (géomètrie solide) | |||

| – | résistance à l’usure |  | ténacité | |||

| – | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • .625"

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| – | (géomètrie légère) | – | (géomètrie solide) | |||

| – | résistance à l’usure |  | ténacité | |||

| – | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

KDMB Ball Nose Platform • .750"

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| – | (géomètrie légère) | – | (géomètrie solide) | |||

| – | résistance à l’usure |  | ténacité | |||

| – | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • 1.00"

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| – | (géomètrie légère) | – | (géomètrie solide) | |||

| – | résistance à l’usure |  | ténacité | |||

| – | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..HC | KC530M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..HC | KC530M |

| M1–M2 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| M3 | .E..GP | KC515M | .E..HC | KC530M | .E..HC | KC530M |

| K1–K2 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| K3 | .E..GP | KC515M | .E..GN | KC515M | .E..GN | KC515M |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | .E..HC | KC530M |

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GN | KC515M |

KDMB Ball Nose Platform • 1.25"

| Groupe Matières | Travaux légers | Applications générales | Travaux lourds | |||

| – | (géomètrie légère) | – | (géomètrie solide) | |||

| – | résistance à l’usure |  | ténacité | |||

| – | Géométrie | Nuance | Géométrie | Nuance | Géométrie | Nuance |

| P1–P2 | .E..GP | KC515M | .E..GP | KC515M | .E..GP | KC515M |

| P3–P4 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| P5–P6 | .E..GP | KC505M | .E..GP | KC515M | .E..GP | KC515M |

| M1–M2 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| M3 | .E..GP | KC515M | .E..GP | KC515M | – | – |

| K1–K2 | .E..GP | KC515M | – | – | – | – |

| K3 | .E..GP | KC515M | – | – | – | – |

| N1–N2 | .E..LD | K115M | .E..LD | K115M | – | – |

| N3 | .E..LD | K115M | .E..LD | K115M | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..LD | K115M | .E..GP | KC515M | ||

| H1 | .E..GP | KC505M | .E..GP | KC505M | .E..GP | KC515M |

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use