Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Take your shop to the next level. See Promotions

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Holemaking

- /

- Solid Carbide Drills

- /

- HP Solid-Carbide Deep Hole Drills

- /

- KenDrill™ HPS • 20 x D • Internal Coolant • Straight Shank • Metric

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

KenDrill™ HPS • 20 x D • Internal Coolant • Straight Shank • Metric

Solid Carbide Deep Hole Drill for Non-Ferrous Materials

Features and benefits

- HP solid carbide deep-hole drills with through coolant for steel, cast iron, stainless steel, high-temperature alloys, and non-ferrous materials.

- Application-specific SC drill for drilling holes up to 20 x D up to 4x faster than conventional HSS and gun drills.

- Broadest diameter range on the market from .0938–.6299″ (2,383–16mm).

- KMH-point geometry is available as a semi-standard, especially for crankshaft applications.

- KN25™ Beyond uncoated grade (B27_HPS) with highly polished surface ensures superior chip evacuation and prevent built-up edge in aluminum and high-temp alloys, even when low-pressure coolant or MQL is applied.

Uses and application

Drilling: Stacked Plates

Drilling

Drilling: Inclined Exit

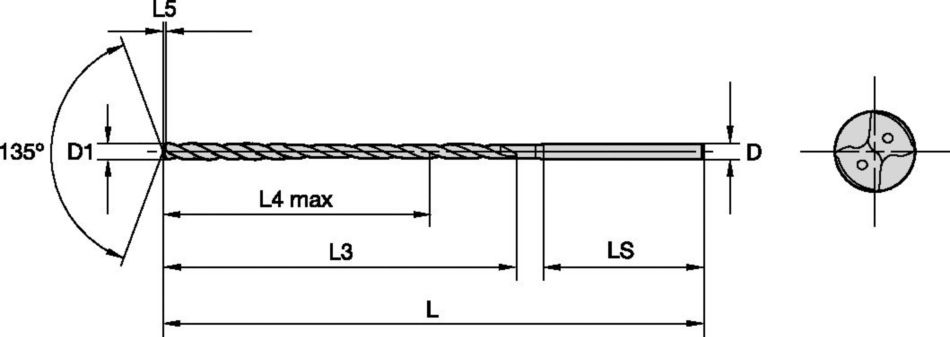

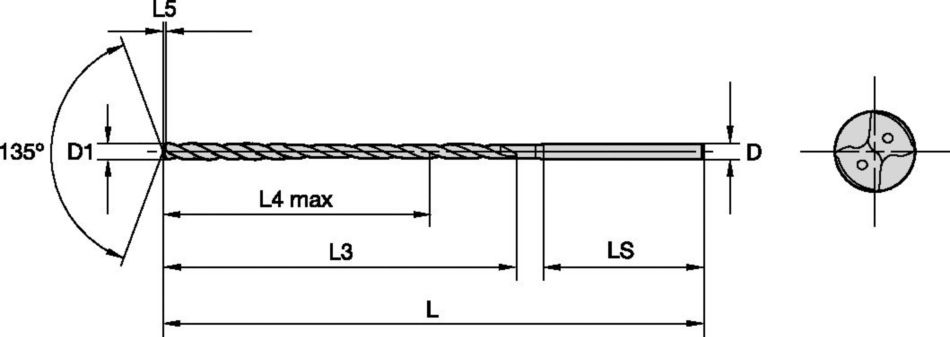

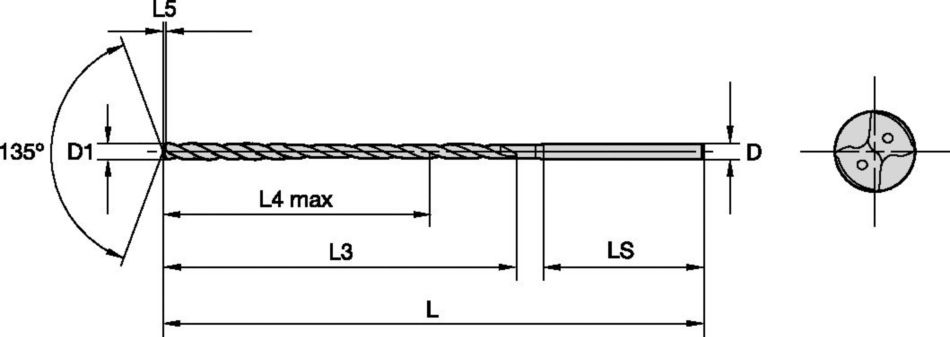

Tool Dimensions: 2flute/4margin/coolant

DIN number 6535

Drilling - Through Coolant

Through Coolant: MQL (Minimum Quantity Lubricant): Drilling

Shank - Cylindrical Plain ≤h6

Helix Angle: 30°

Drilling: Cross-Hole Drilling

| Tolerans • İnç | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| .0394–.1181 | .0000/-.0004 | .0000/-.0006 |

| .0002/.0006 | .0000/-.0003 | |

| .0002/.0008 | .0000/-.0004 | |

| .0003/.0010 | .0000/-.0004 | |

| .0003/.0011 | .0000/-.0005 | |

| Tolerans • Metrik | ||

| Anma ölçüsü aralığı | D1 Tolerans m7 | D Tolerans h6 |

| 1–3 | 0,000/-0,010 | 0,000/-0,014 |

| 0,004/0,016 | 0,000/-0,008 | |

| 0,006/0,021 | 0,000/-0,009 | |

| 0,007/0,025 | 0,000/-0,011 | |

| 0,008/0,029 | 0,000/-0,013 | |

| Malzeme grubu |  |  | |||||||||||

| Malzeme grubu | Kesme hızı | İnç | |||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 1/8 .125 | 3/16 .188 | 1/4 .250 | 5/16 .313 | 3/8 .375 | 1/2 .500 | 0.551 | 5/8 .625 | |||

| N | 1 | 390 | 660 | 980 | IPR | .005–.007 | .005–.007 | .006–.009 | .008–.011 | .010–.014 | .012–.016 | .014–.018 | .016–.020 |

| 2 | 390 | 560 | 980 | IPR | .005–.007 | .006–.008 | .006–.010 | .008–.012 | .011–.015 | .013–.017 | .015–.019 | .017–.021 | |

| 3 | 330 | 490 | 980 | IPR | .005–.007 | .006–.008 | .006–.010 | .008–.012 | .011–.015 | .013–.017 | .015–.019 | .017–.021 | |

| 4 | 260 | 660 | 980 | IPR | .001–.002 | .001–.002 | .001–.002 | .002–.002 | .002–.003 | .002–.003 | .002–.003 | .002–.004 | |

| Malzeme grubu |  |  | |||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | |||

| N | 1 | 120 | 200 | 300 | mm/dev | 0,12 | 0,13 | 0,15 | 0,19 | 0,26 | 0,31 | 0,35 | 0,41 |

| 2 | 120 | 170 | 300 | mm/dev | 0,13 | 0,14 | 0,16 | 0,20 | 0,28 | 0,33 | 0,38 | 0,44 | |

| 3 | 100 | 150 | 300 | mm/dev | 0,13 | 0,14 | 0,16 | 0,20 | 0,28 | 0,33 | 0,38 | 0,44 | |

| 4 | 80 | 200 | 300 | mm/dev | 0,03 | 0,03 | 0,03 | 0,04 | 0,05 | 0,05 | 0,05 | 0,06 | |

|  | ||||||||||||

| Kesme hızı | Metrik | ||||||||||||

| Aralık | Çap başına önerilen ilerleme oranı (f) | ||||||||||||

| Malzeme grubu | Min. | Başlangıç değeri | Maks. | 3,0 | 4,0 | 6,0 | 8,0 | 10,0 | 12,0 | 14,0 | 16,0 | ||

| N | 1 | 120 | 200 | 300 | mm/dev | 0,12–0,17 | 0,13–0,18 | 0,15–0,24 | 0,19–0,29 | 0,26–0,35 | 0,31–0,40 | 0,35–0,45 | 0,41–0,51 |

| 2 | 120 | 170 | 300 | mm/dev | 0,13–0,18 | 0,14–0,19 | 0,16–0,25 | 0,20–0,30 | 0,28–0,37 | 0,33–0,42 | 0,38–0,48 | 0,44–0,54 | |

| 3 | 100 | 150 | 300 | mm/dev | 0,13–0,18 | 0,14–0,19 | 0,16–0,25 | 0,20–0,30 | 0,28–0,37 | 0,33–0,42 | 0,38–0,48 | 0,44–0,54 | |

| 4 | 80 | 200 | 300 | mm/dev | 0,03–0,05 | 0,03–0,06 | 0,03–0,06 | 0,04–0,06 | 0,05–0,07 | 0,05–0,08 | 0,05–0,08 | 0,06–0,09 | |