Welcome

Please confirm your preferences

Update Preferences

Product Suggestions

Product Family suggestions

Hi, User Name

Your Selected Account:

There is an issue with your account. Please contact customer support.

Sold To Account Change Account

Ship To Account Change Account

- Dashboard

- Manage Orders

- Manage Channels

- Address Book

Notifications

Mark all as read- Change Password

- My Profile

- Sign Out

Item(s) successfully added to cart

View Cart

View Cart

Take your shop to the next level. See Promotions

Item(s) successfully added to cart

View Cart

View Cart

Editing Solution

Adding Solution

Solution Name:{{SolutionName}}- Products

- /

- Metalworking Tools

- /

- Milling

- /

- Indexable Milling

- /

- Face Mills

- /

- KSOM Mini

- /

- Inserts for KSOM Mini • OFPT-HB

Product Similar To: [Product Name]

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

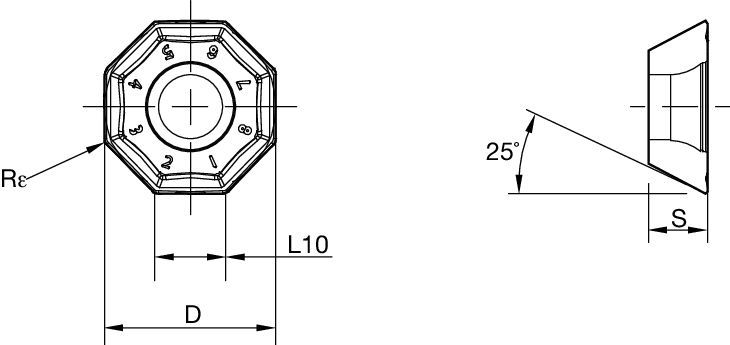

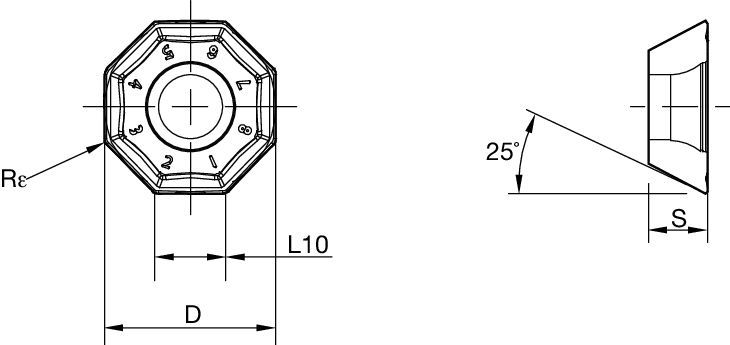

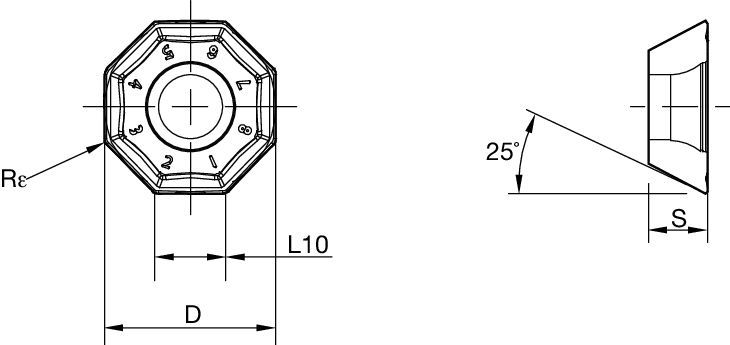

Inserts for KSOM Mini • OFPT-HB

Indexable Inserts

Features and benefits

- First choice for heavy roughing.

- -HB geometry with the strongest cutting edge is the first choice for roughing operations on steel and cast iron.

Insert Selection Guide

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | (Strong geometry) | ||||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | .E..NLB | KC725M | .E..NGB | KC725M | .S..NHB | KC725M |

| P3–P4 | .E..NLB | KCPK30 | .E..NGB | KCPK30 | .S..NHB | KCPK30 |

| P5–P6 | .E..NLB | KCPK30 | .E..NLB | KCPK30 | .E..NGB | KCPK30 |

| M1–M2 | .E..NLB | KC725M | .E..NGB | KC725M | .S..NHB | KC725M |

| M3 | .E..NLB | KCPK30 | .E..NLB | KCPK30 | .S..NLB | KC522M |

| K1–K2 | — | — | .S..NHB | KCPM20 | .S..NHB | KCPK30 |

| K3 | .E..NLB | KCPK30 | .E..NGB | KCPK30 | .S..NHB | KCPK30 |

| N1–N2 | — | — | — | — | — | — |

| N3 | — | — | — | — | — | — |

| S1–S2 | .E..NLB | KC725M | .E..NGB | KC725M | .S..NHB | KC725M |

| S3 | .E..NLB | KC725M | .E..NGB | KC725M | .S..NHB | KC725M |

| S4 | .E..NGB | KC725M | .S..NHB | KC725M | — | — |

| H1 | — | — | — | — | — | — |

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..NLB | 0,25 | 0,37 | 0,43 | 0,18 | 0,28 | 0,32 | 0,16 | 0,24 | 0,28 | 0,15 | 0,22 | 0,26 | 0,15 | 0,22 | 0,26 | .E..NLB |

| .S..NLB | 0,57 | 0,69 | 0,79 | 0,42 | 0,51 | 0,59 | 0,37 | 0,45 | 0,52 | 0,34 | 0,42 | 0,48 | 0,34 | 0,41 | 0,47 | .S..NLB |

| .E..NGB | 0,52 | 0,55 | 0,65 | 0,39 | 0,41 | 0,48 | 0,34 | 0,36 | 0,42 | 0,32 | 0,34 | 0,39 | 0,31 | 0,33 | 0,38 | .E..NGB |

| .S..NHB | 0,57 | 0,78 | 0,91 | 0,42 | 0,58 | 0,68 | 0,37 | 0,5 | 0,59 | 0,34 | 0,47 | 0,55 | 0,34 | 0,46 | 0,54 | .S..NHB |

| Light | General | Heavy |

Recommended Starting Speeds [m/min]

| Material Group | KCK15 | KC520M | KCPM20 | KC522M | KC725M | KCPK30 | |||||||||||||

| P | 1 | – | – | – | – | – | – | 660 | 580 | 535 | 395 | 345 | 325 | 315 | 275 | 255 | 545 | 475 | 440 |

| 2 | – | – | – | – | – | – | 410 | 370 | 330 | 330 | 290 | 240 | 260 | 230 | 195 | 335 | 305 | 275 | |

| 3 | – | – | – | – | – | – | 370 | 330 | 305 | 305 | 255 | 215 | 240 | 205 | 170 | 305 | 275 | 250 | |

| 4 | – | – | – | – | – | – | 275 | 255 | 230 | 270 | 225 | 180 | 215 | 180 | 145 | 225 | 210 | 190 | |

| 5 | – | – | – | – | – | – | 330 | 300 | 275 | 225 | 200 | 180 | 180 | 160 | 145 | 310 | 275 | 255 | |

| 6 | – | – | – | – | – | – | 230 | 200 | 175 | 200 | 150 | 120 | 160 | 120 | 95 | 190 | 165 | – | |

| M | 1 | – | – | – | – | – | – | 270 | 240 | 205 | 245 | 215 | 200 | 205 | 180 | 165 | 250 | 220 | 190 |

| 2 | – | – | – | – | – | – | 245 | 215 | 190 | 225 | 190 | 160 | 185 | 160 | 130 | 225 | 195 | 170 | |

| 3 | – | – | – | – | – | – | 195 | 175 | 150 | 170 | 145 | 115 | 140 | 120 | 95 | 175 | 160 | 140 | |

| K | 1 | 505 | 460 | 410 | 325 | 295 | 260 | 435 | 390 | 350 | 275 | 250 | 220 | – | – | – | – | – | – |

| 2 | 400 | 355 | 330 | 255 | 225 | 215 | 345 | 310 | 280 | 215 | 195 | 180 | – | – | – | – | – | – | |

| 3 | 335 | 300 | 275 | 215 | 190 | 170 | 290 | 255 | 240 | 180 | 160 | 145 | – | – | – | – | – | – | |

| N | 1 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | – | – | – | – | – | – | 50 | 45 | 35 | 45 | 35 | 30 | 45 | 35 | 30 |

| 2 | – | – | – | – | – | – | – | – | – | 50 | 45 | 35 | 45 | 35 | 30 | 45 | 35 | 30 | |

| 3 | – | – | – | – | – | – | – | – | – | 60 | 50 | 35 | 55 | 45 | 30 | 55 | 45 | 30 | |

| 4 | – | – | – | – | – | – | – | – | – | 85 | 60 | 45 | 75 | 55 | 35 | 75 | 55 | 35 | |

| H | 1 | – | – | – | – | – | – | 170 | 140 | 115 | 145 | 110 | 85 | – | – | – | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

Plunging

| max DOC Ap | mm | chipload (fz) |

| AP1 Max | 3,5 | 1 x fz |

| AP2 Max | 9,0 | 0,6 x fz |

Face Milling

| D1 mm | D1 max mm | max ap mm | ramping angle (°) | ramping length mm |

| 32 | 41,1 | 9 | 11,0 | 46,3 |

| 40 | 49,0 | 9 | 7,5 | 68,4 |

| 50 | 58,9 | 9 | 5,0 | 102,9 |

| 63 | 71,8 | 9 | 3,9 | 132,0 |

| 80 | 88,7 | 9 | 2,9 | 177,7 |

Ramping

| max plunging depth | mm |

| AP1 max | 3,2 |

Helical Interpolation

| hole diameter | ||||

| D1 mm | D1 max mm | min mm | max mm | Ap/rev mm |

| 32 | 41,1 | 61,7 | 81,7 | 4,7 |

| 40 | 49,0 | 77,5 | 97,6 | 4,7 |

| 50 | 58,9 | 97,4 | 117,4 | 4,7 |

| 63 | 71,8 | 123,3 | 143,3 | 4,7 |

| 80 | 88,7 | 157,2 | 177,2 | 4,7 |