Product Similar To:

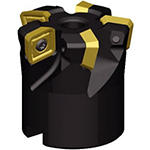

Beyond BLAST™ KSSM™ 45° • High-Feed • 14mm IC • Shell Mills • Metric

Shell Mills

Material Number100001857

Features and benefits

- Use PCT technology, coolant through the insert.

- Engineered to provide the maximum performance in titanium machining.

- Pocketing, ramping, plunging, and helical interpolation capabilities.

Face Milling

Helical Milling

Plunge Milling

Ramping: Blank

Slotting: Ball Nose

Side Milling/Shoulder Milling: Ball Nose

3D Profiling

Milling - Through Coolant

Milling - Side and Face

Pocketing

| Material Group | Light | General | Heavy | |||

| – | (Light geometry) | – | (Strong geometry) | |||

| – | wear |  | toughness | |||

| – | Geometry | Grade | Geometry | Grade | Geometry | Grade |

| P1–P2 | – | – | – | – | – | – |

| P3–P4 | – | – | – | – | – | – |

| P5–P6 | – | – | – | – | – | – |

| M1–M2 | – | – | – | – | – | – |

| M3 | – | – | – | – | – | – |

| K1–K2 | – | – | – | – | – | – |

| K3 | – | – | – | – | – | – |

| N1–N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1–S2 | – | – | – | – | – | – |

| S3 | – | – | – | – | – | – |

| S4 | .E..NGD2 | KC725M | .E..NGN | KC725M | .S..NGN | KC725M |

| H1 | – | – | – | – | – | – |

Recommended Starting Feeds [mm]

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..NGD2 | 0,88 | 1,70 | 2,85 | 0,65 | 1,26 | 2,09 | 0,57 | 1,10 | 1,82 | 0,53 | 1,02 | 1,69 | 0,52 | 1,00 | 1,66 | .E..NGD2 |

| .E..NGN | 0,88 | 1,70 | 2,85 | 0,65 | 1,26 | 2,09 | 0,57 | 1,10 | 1,82 | 0,53 | 1,02 | 1,69 | 0,52 | 1,00 | 1,66 | .E..NGN |

| .S..NGN | 1,04 | 2,03 | 3,41 | 0,78 | 1,50 | 2,49 | 0,68 | 1,30 | 2,16 | 0,63 | 1,22 | 2,01 | 0,62 | 1,19 | 1,97 | .S..NGN |

| Light | General | Heavy |

Recommended Starting Feeds [IPT]

| Light | General | Heavy |

| Insert Geometry | Recommended Starting Feed per Tooth (Fz) in Relation to % of Radial Engagement (ae) | Insert Geometry | ||||||||||||||

| 10% | 20% | 30% | 40% | 50–100% | ||||||||||||

| .E..NGD2 | .035 | .071 | .129 | .026 | .050 | .085 | .022 | .043 | .072 | .021 | .040 | .066 | .020 | .039 | .065 | .E..NGD2 |

| .E..NGN | .035 | .071 | .129 | .026 | .050 | .085 | .022 | .043 | .072 | .021 | .040 | .066 | .020 | .039 | .065 | .E..NGN |

| .S..NGN | .043 | .087 | .165 | .031 | .061 | .103 | .027 | .052 | .086 | .025 | .048 | .080 | .024 | .047 | .078 | .S..NGN |

Recommended Starting Speeds [m/min]

| Material Group | KC725M | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1 | – | – | – |

| 2 | – | – | – | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | 75 | 55 | 35 | |

| H | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

Recommended Starting Speeds [SFM]

| Material Group | KC725M | |||

| P | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | – | – | – | |

| 5 | – | – | – | |

| 6 | – | – | – | |

| M | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| K | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| N | 1 | – | – | – |

| 2 | – | – | – | |

| S | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

| 4 | 240 | 180 | 120 | |

| H | 1 | – | – | – |

| 2 | – | – | – | |

| 3 | – | – | – | |

General Programming Information

| cutter diameter | max ramping | Ap1 max | min hole diameter (DH) | min flat-bottom hole diameter (DH1) | max hole diameter no flat bottom |

| 50mm | 2.11° | 1,65 | 96,34 | 78,02 | 100 |

| 52mm | 1.97° | 1,65 | 100,34 | 82,02 | 104 |

| 63mm | 1.46° | 1,65 | 122,34 | 104,02 | 126 |

| 66mm | 1.37° | 1,65 | 128,34 | 110,02 | 132 |

| 80mm | 1.04° | 1,65 | 156,34 | 138,02 | 160 |

| 100mm | 0.78° | 1,65 | 196,34 | 178,02 | 200 |

| 125mm | 0.59° | 1,65 | 246,34 | 228,02 | 250 |

| Rt | Wt | t |

| 4,1 | 11,0 | 1,3 |

| cutter diameter | max ramping | Ap1 max | min hole diameter (DH) | min flat-bottom hole diameter (DH1) | max hole diameter no flat bottom |

| 2.0" | 2.05° | .065" | 3.856" | 3.134" | 4.0" |

| 2.5" | 1.45° | .065" | 4.856" | 4.134" | 5.0" |

| 3.0" | 1.11° | .065" | 5.856" | 5.134" | 6.0" |

| 4.0" | 0.76° | .065" | 7.856" | 7.134" | 8.0" |

| 5.0" | 0.58° | .065" | 9.856" | 9.134" | 10.0" |

| Rt | Wt | t |

| .161 | .433 | .051 |