Fix-Perfect™

If you are looking for world-class metalworking solutions that boost productivity and consistency, there is no substitute for Kennametal Fix Perfect tools. These tools feature state-of-the-art design, durable construction, and strong materials, helping you achieve success through all applications. Fix-Perfect is also optimal for producing true I.D. and O.D. cuts.

- P Steel (15)

- P0Low-Carbon Steels, Long Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(15)

- P1Low-Carbon Steels, Short Chipping C < .25%; <125 HB; <530 N/mm^2 UTS(15)

- P2Medium and High Carbon Steels C < .25%; <220 HB; <25 HRC; >530 N/mm^2 UTS(15)

- P3Alloy Steels & Tool Steels C > .25%; <330 HB; <35 HRC; 600-850 N/mm^2 UTS(15)

- P4Alloy Steels & Tool Steels C > .25%; 350-420 HB; 35-43 HRC; 850-1400 N/mm^2 UTS(15)

- P5Ferritic, Martensitic, and PH Stainless Steels <330 HB; <35 HRC; 600-900 N/mm^2 UTS(15)

- P6High Strength Ferritic, Martensitic, and PH Stainless Steels 350-450 HB; 35-43 HRC; 900-2400 N/mm^2 UTS(15)

- M Stainless Steel (10)

- M1Austenitic Stainless Steel 130-200 HB; <600 N/mm^2 UTS(10)

- M2High Strength Austenitic Stainless and Cast Stainless Steels 150-230 HB; <25 HRC; >600 N/mm^2 UTS(10)

- M3Duplex Stainless Steel 135-275 HB; <30 HRC; 500-1200 N/mm^2 UTS(10)

- K Cast Iron (15)

- K1Gray Cast Iron 120-290 HB; <32 HRC; 125-500 N/mm^2 UTS(15)

- K2Low and Medium Strength CGI and Ductile Irons 130-260 HB; <28 HRC; <600 N/mm^2 UTS(15)

- K3High Strength Ductile and Austempered Ductile Iron 180-350 HB; <43 HRC; >600 N/mm^2 UTS(15)

- N Non-Ferrous Materials (7)

- N1Wrought Aluminum (7)

- N2Low-Silicon Aluminum Alloys and Magnesium Alloys Si <12.2%(7)

- N4Copper, Brass, Zinc-based on machinability index range of 70-100 (7)

- N5Nylon, Plastics, Rubbers, Phenolics, Resins, Fiberglass (7)

- N6Carbon, Graphite Composites, CFRP (7)

- N7MMC's (7)

- S High-Temp Alloys (10)

- S1Iron-Based, Heat-Resistant Alloys 160-260 HB; 25-48 HRC; 500-1200 N/mm^2 UTS(10)

- S2Cobalt-Based, Heat-Resistant Alloys 250-450 HB; 25-48 HRC; 1000-1450 N/mm^2 UTS(10)

- S3Nickel-Based, Heat Resistant Alloys 160-450 HB; <48 HRC; 600-1700 N/mm^2 UTS(10)

- S4Titanium and Titanium Alloys 300-400 HB; 33-43 HRC; 900-1600 N/mm^2 UTS(10)

- H Hardened Materials (4)

- H1Hardened Materials 44-48 HRC(4)

- H2Hardened Materials 48-55 HRC(4)

- H3Hardened Materials 56-60 HRC(3)

- C CFRP Materials (7)

- C1CFRP, CFRP / CFRP (7)

- C2CFRP / Aluminium CFRP / Non-Ferrous (7)

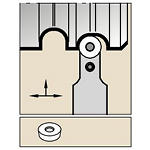

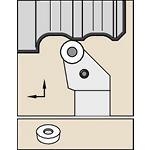

Facing (15)

Multiple Direction Cutting (15)

Profiling (6)

Turning (15)

- Heavily Interrupted Cut (12)

- Lightly Interrupted Cut (15)

- Smooth Cut (15)

- 5.906 in(6)

- 6.694 in(6)

- 9.843 in(3)

- 150.0 mm(6)

- 170.0 mm(6)

- 250.0 mm(3)

- 0.157 in(1)

- 0.197 in(2)

- 0.237 in(3)

- 0.313 in(3)

- 0.315 in(3)

- 0.394 in(3)

- 0.492 in(3)

- 4.0 mm(1)

- 5.0 mm(2)

- 6.0 mm(3)

- 7.95 mm(3)

- 8.0 mm(3)

- 10.0 mm(3)

- 12.5 mm(3)

- 13E (8)

- AC5 (6)

- CG4 (3)

- CL4 (5)

- CM3 (12)

- CM5 (11)

- CPX (6)

- GX (3)

- K313 (7)

- K420 (5)

- K68 (7)

- KC5010 (10)

- KC5025 (7)

- KC5410 (4)

- KC730 (7)

- KC732 (4)

- KC8050 (12)

- KC810 (1)

- KC850 (7)

- KC910 (4)

- KC9110 (14)

- KC9125 (14)

- KC9240 (9)

- KC9240NEW (9)

- KC9315 (12)

- KC9320 (3)

- KCD25 (1)

- KCK15 (6)

- KCK15B (9)

- KCK20 (7)

- KCK20B (7)

- KCM25 (7)

- KCM25B (3)

- KCP10 (13)

- KCP10B (13)

- KCP25 (14)

- KCP25B (15)

- KCP25C (15)

- KCP30 (11)

- KCP30B (7)

- KCPK05 (9)

- KCS10 (10)

- KCS10B (7)

- KCU10 (10)

- KCU10B (7)

- KCU25 (10)

- KCU25B (4)

- KM1 (3)

- KY1615 (11)

- MC2 (6)

- NL300 (3)

- NL920 (3)

- TN7035 (3)

- L (4)

- N (6)

- R (5)

- 16.5 mm(1)

- 17.5 mm(1)

- 18.5 mm(1)

- 20.5 mm(1)

- 26.0 mm(1)

- 30.0 mm(1)

- 32.0 mm(4)

- 32.5 mm(1)

- 40.0 mm(2)

- 50.0 mm(2)

- 0.65 in(1)

- 0.69 in(1)

- 0.728 in(1)

- 0.807 in(1)

- 1.024 in(1)

- 1.181 in(1)

- 1.26 in(4)

- 1.28 in(1)

- 1.575 in(2)

- 1.969 in(2)

- B (14)

- S (1)

- 0.63 in(1)

- 0.946 in(2)

- 1.26 in(1)

- 1.299 in(1)

- 3.071 in(1)

- 16.0 mm(1)

- 24.0 mm(2)

- 32.0 mm(1)

- 33.0 mm(1)

- 78.0 mm(1)

- C A (11)

- H T (11)

- H W (15)

- 0.984 in(6)

- 1.26 in(6)

- 1.575 in(3)

- 25.0 mm(6)

- 32.0 mm(6)

- 40.0 mm(3)

- 0.984 in(9)

- 1.26 in(3)

- 1.575 in(3)

- 25.0 mm(9)

- 32.0 mm(3)

- 40.0 mm(3)