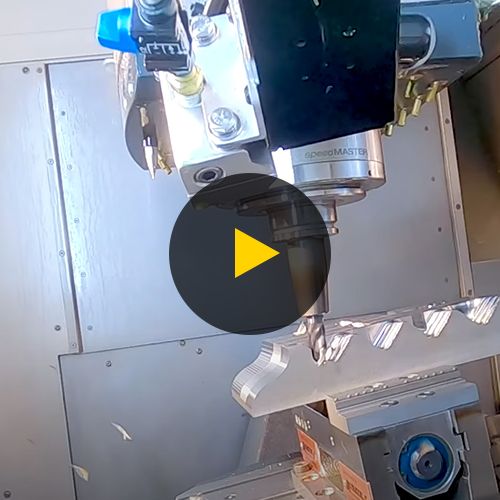

Chips From the Real World – KOR™5 Solid Carbide End Mill

Machining a particular aluminum part for a customer, Aluro CNC was using a competitor's end mill – a 16-millimeter diameter, 3 flute end mill. The application required the shop to open a hole in a block of aluminum starting with an 80-millimeter diameter hole. This took 5 minutes and 16 seconds. When using KOR5 the shop was able to shave machine time down to 1 minute and 54 seconds, saving over 3 minutes per part. The KOR5 freed up more time on their machine to make more chips. What can it do for your shop?