Producto similar a:

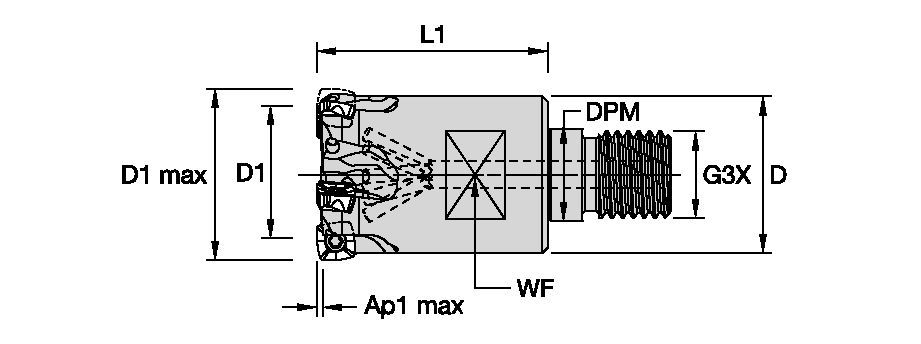

7792VXP06 Series • End Mill • Screw-On • Metric

High-Feed copy milling cutter for multiple materials.

Número de material5681122

Referencia ISO7792VXP06SA020Z3R35Referencia ANSI7792VXP06SA020Z3R35

- P Acero

- M Acero inoxidable

- K Fundición

- N Materiales no ferrosos

- S Aleaciones de alta temperatura

- H Materiales endurecidos

Spiral Circular

Slotting: Shoulder

Planeado

Fresado helicoidal

Rectificado en rampa: Material en bruto

Mecanizado de alojamientos

Avellanado

Vaciado: Nariz de bola

Inclined Square End Mill

Sending to {{cadTool}} in progress...

Downloaded file will be available after import in the {{cadTool}} tool library.

- Información general

- Datos de aplicación

- Descargas

- Piezas compatibles Lado máquina

- Piezas compatibles Lado de la pieza

- Piezas de recambio

- Comentarios

- Preguntas y Respuestas

| Número de material | 5681122 |

| Referencia ISO | 7792VXP06SA020Z3R35 |

| Referencia ANSI | 7792VXP06SA020Z3R35 |

| Calidad | S |

| Diámetro de corte máximo [D1MAX] | 20 mm |

| Diámetro de corte máximo [D1MAX] | .787 in |

| Diámetro de corte efectivo [D1] | 11.6 mm |

| Diámetro de corte efectivo [D1] | .457 in |

| Longitud de cabeza [L2] | 35 mm |

| Longitud de cabeza [L2] | 1.378 in |

| Tamaño de rosca de conexión externo [G3X] | M10 |

| Diámetro piloto Lateral de la máquina [DPM] | 10.5 mm |

| Diámetro piloto Lateral de la máquina [DPM] | .4134 in |

| 1.ª profundidad de corte máxima [AP1MAX] | 0.9 mm |

| 1.ª profundidad de corte máxima [AP1MAX] | .035 in |

| Número de canales [Z] | 3 |

Materiales de la pieza de trabajo

- Acero

- Acero inoxidable

- Fundición

- Materiales no ferrosos

- Aleaciones de alta temperatura

- Materiales endurecidos

Uses and application

Spiral Circular

Slotting: Shoulder

Planeado

Fresado helicoidal

Rectificado en rampa: Material en bruto

Mecanizado de alojamientos

Avellanado

Vaciado: Nariz de bola

Inclined Square End Mill

Features and benefits

- Internal coolant supply

- Positive design to support low cutting forces and applications with long overhang

Crear una solución para calcular la velocidad y el avance

Después de crear una solución, sólo tiene que elegir el icono Avance y Velocidad y nuestro sistema le ofrecerá recomendaciones. Puede personalizar la información añadiendo su máquina y especificaciones o realizar ajustes utilizando los controles deslizantes.

Insert Selection

Guía de selección de plaquitas • IC 06

| 7792 Series • IC06 • Insert Selection Guide | ||||||

| Grupo de materiales | Mecanizado ligero | Aplicaciones generales | Mecanizado intensivo | |||

| – | (Geometría ligera) | – | (Geometría fuerte) | |||

| – | resistencia |  | tenacidad | |||

| – | Geometría | Calidad | Geometría | Calidad | Geometría | Calidad |

| P1-P2 | ...M41 | KCPM40 | ...D41 | SP6519 | ...D41 | X400 |

| P3-P4 | ...M41 | KCPM40 | …D | KC522M | …D | KCPM40 |

| P5-P6 | ...M41 | KCPM40 | ...D41 | X500 | ...D41 | X500 |

| M1-M2 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| M3 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| K1-K2 | …D | KCPK30 | …D | KCPK30 | …D | KCPK30 |

| K3 | …D | KCPK30 | …D | KCPK30 | …D | KCPK30 |

| N1-N2 | – | – | – | – | – | – |

| N3 | – | – | – | – | – | – |

| S1-S2 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| S3 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| S4 | ...M41 | KCSM40 | ...D41 | KCSM40 | ...D41 | KCSM40 |

| H1 | …D | KCKP10 | …D | KCKP10 | …D | KCPM40 |

Feeds

| Avances iniciales recomendados [mm] • Alto avance | |||||||

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | ||||||

| DOC | 30% | 40–100% | |||||

| (mm) | L | M | H | L | M | H | |

| .S..D | 0,9 | 0,31 | 0,62 | 0,92 | 0,28 | 0,56 | 0,84 |

| .S..D | 0,6 | 0,35 | 0,70 | 1,04 | 0,32 | 0,64 | 0,94 |

| .S..D | 0,5 | 0,38 | 0,75 | 1,12 | 0,34 | 0,69 | 1,02 |

| .E..D41 | 0,9 | 0,17 | 0,46 | 0,77 | 0,16 | 0,42 | 0,70 |

| .E..D41 | 0,6 | 0,19 | 0,52 | 0,87 | 0,18 | 0,48 | 0,79 |

| .E..D41 | 0,5 | 0,21 | 0,56 | 0,94 | 0,19 | 0,52 | 0,85 |

| .E..M41 | 0,8 | 0,17 | 0,46 | 0,77 | 0,16 | 0,42 | 0,70 |

| .E..M41 | 0,6 | 0,19 | 0,52 | 0,87 | 0,18 | 0,48 | 0,79 |

| .E..M41 | 0,5 | 0,21 | 0,56 | 0,94 | 0,19 | 0,52 | 0,85 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||

| 7792 Series • IC06 • Recommended Starting Feeds for Plunging [mm/th] | ||||

| Geometría de plaquita |  | Avance por diente programado (fz) | ||

| L | M | H | ||

| .S..D | 0,10 | 0,20 | 0,30 | |

| .E..D41 | 0,06 | 0,15 | 0,25 | |

| .E..M41 | 0,06 | 0,15 | 0,25 | |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | ||||

| 7792 Series • IC06 • Recommended Starting Feeds for Plunging [IPT] | ||||

| Geometría de plaquita |  | Avance por diente programado (fz) | ||

| L | M | H | ||

| .S..D | 0.004 | 0.008 | 0.012 | |

| .E..D41 | 0.002 | 0.006 | 0.010 | |

| .E..M41 | 0.002 | 0.006 | 0.010 | |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | ||||

| Avances iniciales recomendados [mm] • Alto avance | |||||||

| Geometría de plaquita | Avance inicial recomendado por diente (Fz) en relación con % de contacto radial (ae) | ||||||

| DOC | 30% | 40–100% | |||||

| (Inch) | L | M | H | L | M | H | |

| .S..D | 0.035 | 0.012 | 0.024 | 0.036 | 0.011 | 0.022 | 0.033 |

| .S..D | 0.025 | 0.014 | 0.029 | 0.043 | 0.013 | 0.026 | 0.039 |

| .S..D | 0.02 | 0.016 | 0.032 | 0.048 | 0.015 | 0.029 | 0.043 |

| .E..D41 | 0.035 | 0.007 | 0.019 | 0.031 | 0.006 | 0.017 | 0.028 |

| .E..D41 | 0.025 | 0.008 | 0.022 | 0.037 | 0.007 | 0.020 | 0.033 |

| .E..D41 | 0.02 | 0.009 | 0.025 | 0.041 | 0.008 | 0.022 | 0.037 |

| .E..M41 | 0.031 | 0.007 | 0.019 | 0.031 | 0.006 | 0.017 | 0.028 |

| .E..M41 | 0.025 | 0.008 | 0.022 | 0.037 | 0.007 | 0.020 | 0.033 |

| .E..M41 | 0.02 | 0.009 | 0.025 | 0.041 | 0.008 | 0.022 | 0.037 |

| L = Light Machining; M = Medium Machining; H = Heavy Machining NOTE: Use Light Machining values as starting feed rate. | |||||||

Speeds

Velocidades iniciales recomendadas (m/min)

| 7792 Series IC06 • Recommended Starting Speed [m/min] | |||||||||||||||||||||||||||||||

| Calidad | KC510M | KC522M | KCPK30 | KCKP10 | KCPM40 | KCSM40 | SP6519 | SC6525 | X400 | X500 | |||||||||||||||||||||

| Grosor de viruta hex mm | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | |||||||||||

| Grupo de materiales | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | |

| P | 1 | – | – | – | 330 | 285 | 270 | 455 | 395 | 370 | 300 | 295 | 260 | 295 | 260 | 245 | 350 | 320 | 300 | 295 | 215 | 130 | 371 | 254 | 142 | 260 | 190 | 120 | 270 | 200 | 130 |

| 2 | – | – | – | 275 | 240 | 200 | 280 | 255 | 230 | 310 | 275 | 240 | 250 | 215 | 180 | 300 | 270 | 220 | 260 | 190 | 115 | 325 | 225 | 121 | 230 | 170 | 105 | 240 | 280 | 115 | |

| 3 | – | – | – | 255 | 215 | 175 | 255 | 230 | 205 | 275 | 240 | 205 | 230 | 195 | 160 | 280 | 240 | 195 | 230 | 165 | 100 | 292 | 200 | 104 | 200 | 150 | 95 | 210 | 155 | 100 | |

| 4 | 245 | 200 | 170 | 225 | 185 | 150 | 225 | 185 | 160 | 240 | 205 | 160 | 205 | 170 | 135 | 240 | 205 | 165 | 175 | 125 | 75 | 208 | 146 | 79 | 150 | 110 | 70 | 160 | 120 | 75 | |

| 5 | – | – | – | 185 | 170 | 150 | 190 | 170 | 150 | 205 | 160 | 125 | 170 | 155 | 135 | 200 | 180 | 160 | 140 | 105 | 70 | 158 | 121 | 79 | – | – | – | 130 | 100 | 70 | |

| 6 | – | – | – | 165 | 125 | 100 | 160 | 135 | 110 | 160 | 125 | 110 | 150 | 115 | 90 | 180 | 140 | 100 | 120 | 85 | 50 | 142 | 100 | 58 | – | – | – | 110 | 80 | 50 | |

| M | 1 | – | – | – | 205 | 180 | 165 | 205 | 185 | 155 | – | – | – | 195 | 170 | 155 | 260 | 210 | 185 | 270 | 195 | 115 | 192 | 154 | 121 | – | – | – | 250 | 185 | 115 |

| 2 | – | – | – | 185 | 160 | 130 | 185 | 160 | 140 | – | – | – | 175 | 150 | 125 | 235 | 180 | 145 | 235 | 170 | 105 | 258 | 183 | 108 | – | – | – | 220 | 160 | 100 | |

| 3 | – | – | – | 140 | 120 | 95 | 145 | 130 | 115 | – | – | – | 130 | 115 | 90 | 175 | 145 | 110 | 195 | 140 | 85 | 208 | 150 | 92 | – | – | – | 180 | 130 | 80 | |

| K | 1 | 295 | 265 | 240 | 230 | 205 | 185 | 295 | 265 | 240 | 410 | 330 | 240 | – | – | – | – | – | – | – | – | – | 392 | 271 | 146 | – | – | – | – | – | – |

| 2 | 230 | 205 | 190 | 180 | 160 | 150 | 235 | 210 | 190 | 280 | 245 | 190 | – | – | – | – | – | – | – | – | – | 304 | 208 | 117 | – | – | – | – | – | – | |

| 3 | 195 | 175 | 160 | 150 | 135 | 120 | 195 | 175 | 160 | 240 | 195 | 160 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1 | 640 | 570 | 525 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 580 | 535 | 490 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 580 | 535 | 490 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 30 | 50 | 40 | 25 | 55 | 40 | 20 | – | – | – | – | – | – | 45 | 35 | 25 |

| 2 | – | – | – | 40 | 35 | 25 | – | – | – | – | – | – | 40 | 35 | 30 | 55 | 40 | 25 | 45 | 35 | 20 | – | – | – | – | – | – | 45 | 30 | 20 | |

| 3 | – | – | – | 50 | 40 | 25 | – | – | – | – | – | – | 50 | 40 | 30 | 65 | 45 | 30 | 55 | 40 | 25 | – | – | – | – | – | – | 50 | 40 | 25 | |

| 4 | – | – | – | 50 | 45 | 35 | 50 | 45 | 35 | – | – | – | 55 | 50 | 35 | 75 | 60 | 40 | 80 | 55 | 35 | – | – | – | – | – | – | 60 | 50 | 35 | |

| H | 1 | 130 | 105 | 80 | 120 | 90 | 70 | – | – | – | 140 | 110 | 90 | – | – | – | – | – | – | – | – | – | – | – | – | 95 | 70 | 45 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 80 | 60 | 35 | – | – | – | |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||||||||||||||

| 7792 Series IC06 • Recommended Starting Speed [SFM] | |||||||||||||||||||||||||||||||

| Calidad | KC510M | KC522M | KCPK30 | KCKP10 | KCPM40 | KCSM40 | SP6519 | SC6525 | X400 | X500 | |||||||||||||||||||||

| Chip Thickness hex Inch | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | Mín | Máx. | |||||||||||

| Grupo de materiales | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | Máx. | Inicio | Mín | |

| P | 1 | – | – | – | 1085 | 935 | 885 | 1495 | 1295 | 1215 | 985 | 970 | 855 | 970 | 855 | 805 | 1150 | 1050 | 985 | 970 | 705 | 425 | 1217 | 833 | 458 | 855 | 625 | 395 | 885 | 655 | 425 |

| 2 | – | – | – | 900 | 785 | 655 | 920 | 835 | 755 | 1015 | 900 | 785 | 820 | 705 | 590 | 985 | 885 | 720 | 855 | 625 | 375 | 1067 | 742 | 396 | 755 | 560 | 345 | 785 | 920 | 375 | |

| 3 | – | – | – | 835 | 705 | 575 | 835 | 755 | 675 | 900 | 785 | 675 | 755 | 640 | 525 | 920 | 785 | 640 | 755 | 540 | 330 | 950 | 654 | 346 | 655 | 490 | 310 | 690 | 510 | 330 | |

| 4 | 805 | 655 | 560 | 740 | 605 | 490 | 740 | 605 | 525 | 785 | 675 | 525 | 675 | 560 | 445 | 785 | 675 | 540 | 575 | 410 | 245 | 692 | 475 | 258 | 490 | 360 | 230 | 525 | 395 | 245 | |

| 5 | – | – | – | 605 | 560 | 490 | 625 | 560 | 490 | 675 | 525 | 410 | 560 | 510 | 445 | 655 | 590 | 525 | 460 | 345 | 230 | 525 | 396 | 258 | – | – | – | 425 | 330 | 230 | |

| 6 | – | – | – | 540 | 410 | 330 | 525 | 445 | 360 | 525 | 410 | 360 | 490 | 375 | 295 | 590 | 460 | 330 | 395 | 280 | 165 | 458 | 329 | 196 | – | – | – | 360 | 260 | 165 | |

| M | 1 | – | – | – | 675 | 590 | 540 | 675 | 605 | 510 | – | – | – | 640 | 560 | 510 | 855 | 690 | 605 | 885 | 640 | 375 | 625 | 508 | 396 | – | – | – | 820 | 605 | 375 |

| 2 | – | – | – | 605 | 525 | 425 | 605 | 525 | 460 | – | – | – | 575 | 490 | 410 | 770 | 590 | 475 | 770 | 560 | 345 | 854 | 604 | 358 | – | – | – | 720 | 525 | 330 | |

| 3 | – | – | – | 460 | 395 | 310 | 475 | 425 | 375 | – | – | – | 425 | 375 | 295 | 575 | 475 | 360 | 640 | 460 | 280 | 692 | 492 | 296 | – | – | – | 590 | 425 | 260 | |

| K | 1 | 970 | 870 | 785 | 755 | 675 | 605 | 970 | 870 | 785 | 1345 | 1085 | 785 | – | – | – | – | – | – | – | – | – | 1279 | 883 | 475 | – | – | – | – | – | – |

| 2 | 755 | 675 | 625 | 590 | 525 | 490 | 770 | 690 | 625 | 920 | 805 | 625 | – | – | – | – | – | – | – | – | – | 1000 | 692 | 375 | – | – | – | – | – | – | |

| 3 | 640 | 575 | 525 | 490 | 445 | 395 | 640 | 575 | 525 | 785 | 640 | 525 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| N | 1 | 2100 | 1870 | 1725 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| 2 | 1905 | 1755 | 1610 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| 3 | 1905 | 1755 | 1610 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | |

| S | 1 | – | – | – | 130 | 115 | 80 | – | – | – | – | – | – | 130 | 115 | 100 | 165 | 130 | 80 | 180 | 130 | 65 | – | – | – | – | – | – | 150 | 115 | 80 |

| 2 | – | – | – | 130 | 115 | 80 | – | – | – | – | – | – | 130 | 115 | 100 | 180 | 130 | 80 | 150 | 115 | 65 | – | – | – | – | – | – | 150 | 100 | 65 | |

| 3 | – | – | – | 165 | 130 | 80 | – | – | – | – | – | – | 165 | 130 | 100 | 215 | 150 | 100 | 180 | 130 | 80 | – | – | – | – | – | – | 165 | 130 | 80 | |

| 4 | – | – | – | 165 | 150 | 115 | 165 | 150 | 115 | – | – | – | 180 | 165 | 115 | 245 | 195 | 130 | 260 | 180 | 115 | – | – | – | – | – | – | 195 | 165 | 115 | |

| H | 1 | 425 | 345 | 260 | 395 | 295 | 230 | – | – | – | 460 | 360 | 295 | – | – | – | – | – | – | – | – | – | – | – | – | 310 | 230 | 150 | – | – | – |

| 2 | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 260 | 195 | 115 | – | – | – | |

| Recommended Starting Speed are pointing to 90° Shoulder Milling . Starting Speed for Face and Copy Milling can be Increased by 20 %. As the average chip thickness increases, speed should be decreased. Material groups P, M, K and H show recommended starting speeds for dry machining. For wet machining, reduce speed by 20%. Material groups N and S show recommended starting speeds for wet machining. Not recommended for dry machining. | |||||||||||||||||||||||||||||||

Datos de aplicación

| 7792 Series IC06 • Ramping Application Data • Straight-Edged Inserts • Metric | |||||

| D1 máx | Ángulo de fresado descendente(°) | ae máx | Paso de planeado | DH min [mm] - (min hole diameter) | DH mín (diámetro de agujero mín.) |

| 16 | 7.0° | 3 | 7.6 | 22 | 30 |

| 20 | 4.3° | 3 | 11.6 | 30 | 38 |

| 25 | 2.6° | 3 | 16.6 | 42 | 50 |

| 32 | 1.7° | 3 | 23.6 | 54 | 62 |

| 35 | 1.3° | 3 | 23.6 | 60 | 68 |

| NOTE: Maximum ramp angle decreases as nose radius increases. | |||||

| 7792 Series IC06 • Ramping Application Data • Curved Edges • Metric | |||||

| D1 máx | Ángulo de fresado descendente(°) | ae máx | Paso de planeado | DH min [mm] - (min hole diameter) | DH mín (diámetro de agujero mín.) |

| 16 | 5.9° | 3 | 7,6 | 22 | 30 |

| 20 | 3.4° | 3 | 11,6 | 30 | 38 |

| 25 | 2.2° | 3 | 16,6 | 42 | 50 |

| 32 | 1.4° | 3 | 23,6 | 54 | 62 |

| 35 | 1.3° | 3 | 23,6 | 60 | 68 |

| NOTE: Maximum ramp angle decreases as nose radius increases. | |||||

| 7792 Series IC06 • Ramping Application Data • Curved Edges • Inch | |||||

| D1 máx | Ángulo de fresado descendente(°) | ae máx | Paso de planeado | DH min [Inch] - (min hole diameter) | DH mín (diámetro de agujero mín.) |

| 0.63 | 8.2° | 0.118 | 0.26 | 0.856 | 1.171 |

| 0.75 | 6.7° | 0.118 | 0.38 | 1.106 | 1.421 |

| 1.00 | 4.3° | 0.118 | 0.63 | 1.606 | 1.921 |

| 1.25 | 2.6° | 0.118 | 0.88 | 2.106 | 2.421 |

| NOTE: Maximum ramp angle decreases as nose radius increases. | |||||

| 7792 Series IC06 • Ramping Application Data • Straight-Edged Inserts • Inch | |||||

| D1 máx | Ángulo de fresado descendente(°) | ae máx | Paso de planeado | DH min [Inch] - (min hole diameter) | DH mín (diámetro de agujero mín.) |

| 0.63 | 7.2° | 0.118 | 0.282 | 0.856 | 1.171 |

| 0.75 | 4.8° | 0.118 | 0.380 | 1.106 | 1.421 |

| 1.00 | 2.5° | 0.118 | 0.630 | 1.606 | 1.921 |

| 1.25 | 1.7° | 0.118 | 0.880 | 2.106 | 2.421 |

| NOTE: Maximum ramp angle decreases as nose radius increases. | |||||

| 7792 Series IC06 • Programing Data • Curved Edges • Metric [mm] | |||

| IC | Radio de esquina | R | L |

| 06 | 0,8 | 1,37 | 0,4 |

| 09 | 0,8 | 2,01 | 0,73 |

| 1,2 | 2,27 | 0,67 | |

| 12 | 0,8 | 2,5 | 1,02 |

| 1,2 | 2,73 | 0,97 | |

| 16 | 1,2 | 4,18 | 1,46 |

| 7792 Series IC06 • Programing Data • Straight-Edged Inserts • Metric [mm] | |||

| IC | Radio de esquina | R | L |

| 06 | 0,8 | 1,46 | 0,529 |

| 09 | 0,8 | 2,13 | 1,025 |

| 1,2 | 2,25 | 0,95 | |

| 12 | 0,8 | 2,46 | 1,33 |

| 1,2 | 2,79 | 1,27 | |

| 2 | 3,42 | 1,13 | |

| 16 | 1,2 | 3,56 | 1,82 |

| CNC Program • Corner Radius Definition The use of common CAD/CAM systems requires a round insert dimension to be known for cavity machining. For finish pass applications: Wiper facet for finishing use max. feed 0,8mm. | |||

| 7792 Series IC06 • Programing Data • Curved Edges • Inch [inch] | |||

| IC | Radio de esquina | R | L |

| 06 | 0.031 | 0.057 | 0.016 |

| 09 | 0.031 | 0.079 | 0.028 |

| 0.047 | 0.089 | 0.026 | |

| 12 | 0.031 | 0.098 | 0.040 |

| 0.047 | 0.107 | 0.038 | |

| 16 | 0.047 | 0.164 | 0.057 |

| 7792 Series IC06 • Programing Data • Straight-Edged Inserts • Inch [inch] | |||

| IC | Radio de esquina | R | L |

| 06 | 0.031 | 0.057 | 0.021 |

| 09 | 0.031 | 0.084 | 0.040 |

| 0.047 | 0.088 | 0.037 | |

| 12 | 0.031 | 0.097 | 0.052 |

| 0.047 | 0.109 | 0.050 | |

| 0.079 | 0.134 | 0.044 | |

| 16 | 0.047 | 0.140 | 0.072 |

| CNC Program • Corner Radius Definition The use of common CAD/CAM systems requires a round insert dimension to be known for cavity machining. For finish pass applications: Wiper facet for finishing use max. feed 0.031". | |||

CAD Drawings Models

Can’t find the file type you’re looking for?

Product data

I have read and accepted the Terms & Conditions of use